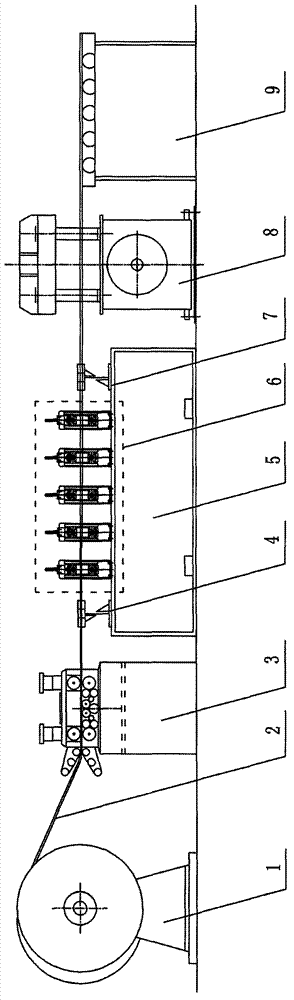

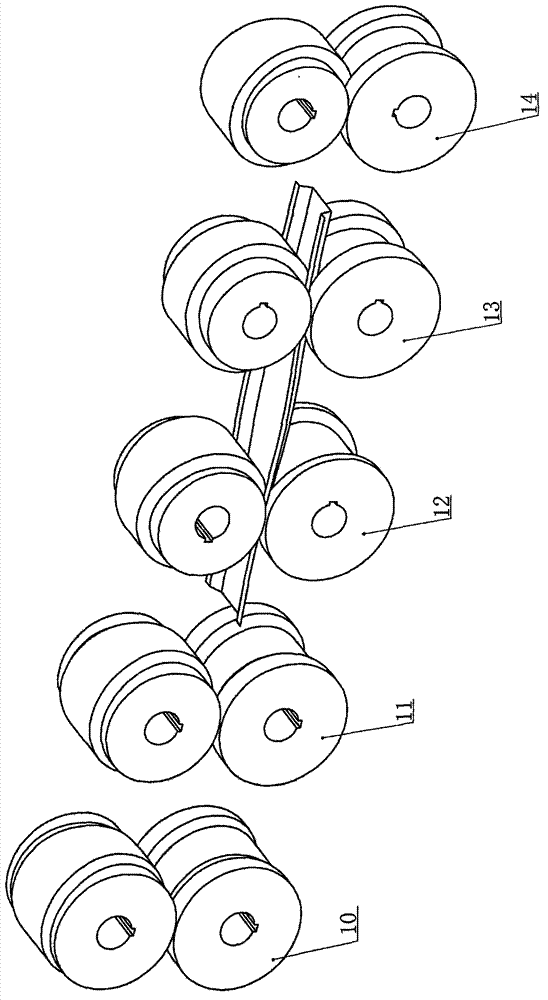

Roll bending forming method and device of cap-shaped sectional material with variable cross section

A technology of variable cross-section and roll bending, which is applied in the field of roll forming and device of variable cross-section hat-shaped profiles, can solve the problems of high cost and low production efficiency, and achieve the effects of low cost, high production efficiency, and easy assembly and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

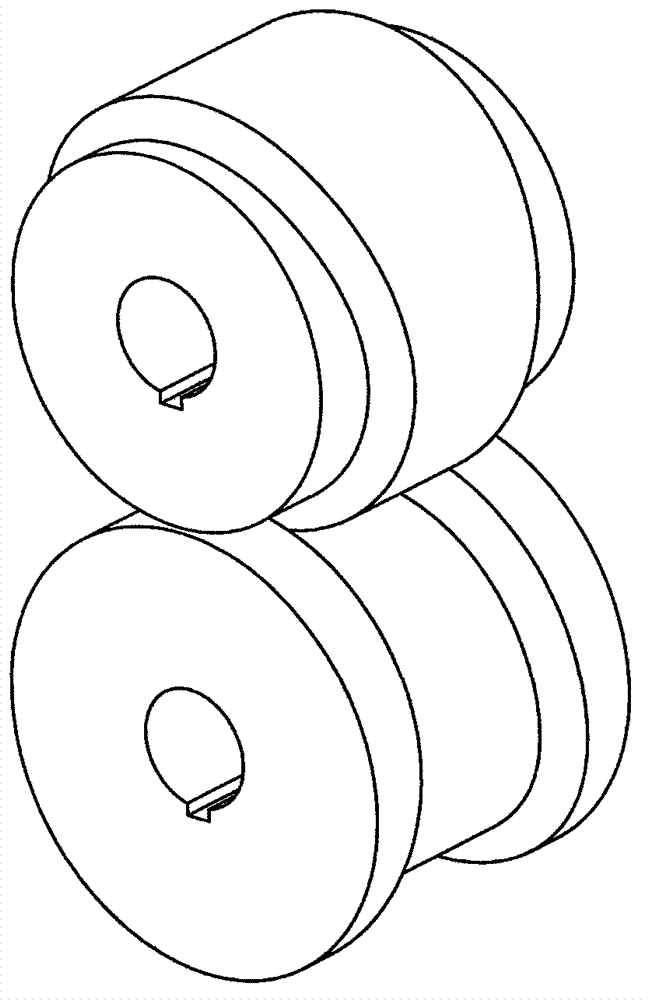

Method used

Image

Examples

Embodiment 1

[0026] Adopt the variable cross-section hat-shaped profile roll forming device of the present invention, the section of formed profile is as follows Figure 5 shown. The metal sheet used is 446 ferritic stainless steel with a forming thickness of about 1.5mm. The forming speed can be set to 300mm / s according to the characteristics of the plate material to be processed, and the rolling speed of the roll can be set by the forming speed. After roll forming, the Figure 5 Variable-section hat profiles of the cross-sectional shape shown.

[0027] To sum up, the rolling forming device for variable-section hat-shaped profiles according to the present invention is easy to assemble and debug, and has high production efficiency and low cost for mass production of hat-shaped variable-section profiles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com