Fixture on lockset perforating machine

A punching machine and fixture technology, applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of low processing efficiency and processing accuracy, affecting the accuracy of punching, affecting the qualification rate of locks, etc., to improve the processing efficiency. Efficiency and machining accuracy, novel structure, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

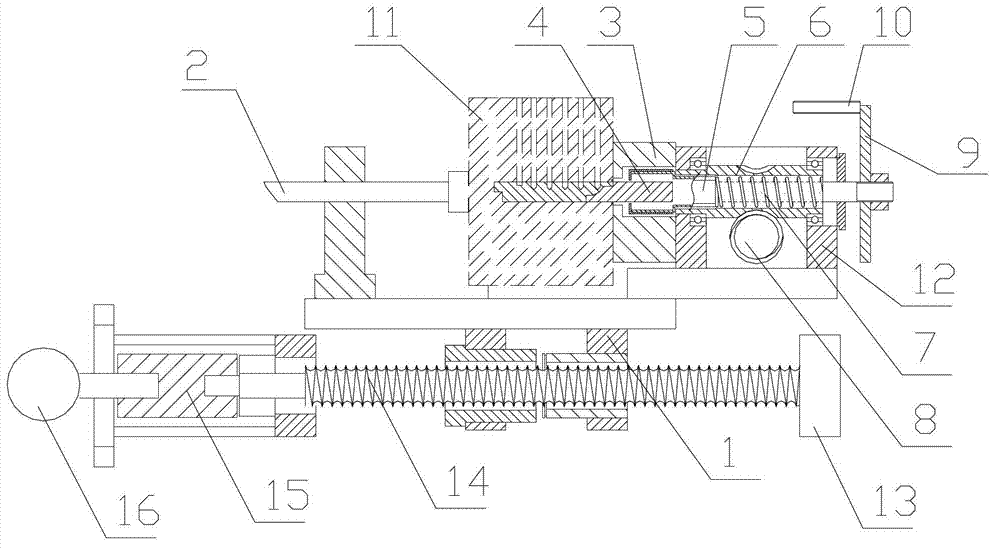

[0009] Attached below figure 1 The present invention is further described.

[0010] like figure 1 The clamp on the lock drilling machine shown is composed of a clamp moving device and a position adjusting device, and the position adjusting device is installed on the clamp moving device.

[0011] Fixture moving device comprises motor 16, coupling 15, screw mandrel 14, mounting frame 13, slide block 1, movable clamping block 2 and fixed clamping block 3, and screw mandrel 14 is contained on the mounting frame 13, and motor 16 passes through joint. The shaft device 15 is connected with the screw mandrel 13, the slide block 1 is installed on the screw mandrel 13, the motor 16 drives the slide block 1 to move through the screw mandrel 14, the movable clamping block 2 and the fixed clamping block 3 are assembled on the slide block 1, to be The processed lockset 11 is between the movable clamping block 2 and the fixed clamping block 3 .

[0012] The position adjustment device incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com