Hydraulic cold-pressed encryption equipment

An encryption machine, hydraulic technology, applied in the direction of recycling technology, plastic recycling, etc., can solve the problems of time-consuming, laborious, harmful gas, affecting production efficiency, etc., to achieve the effect of easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

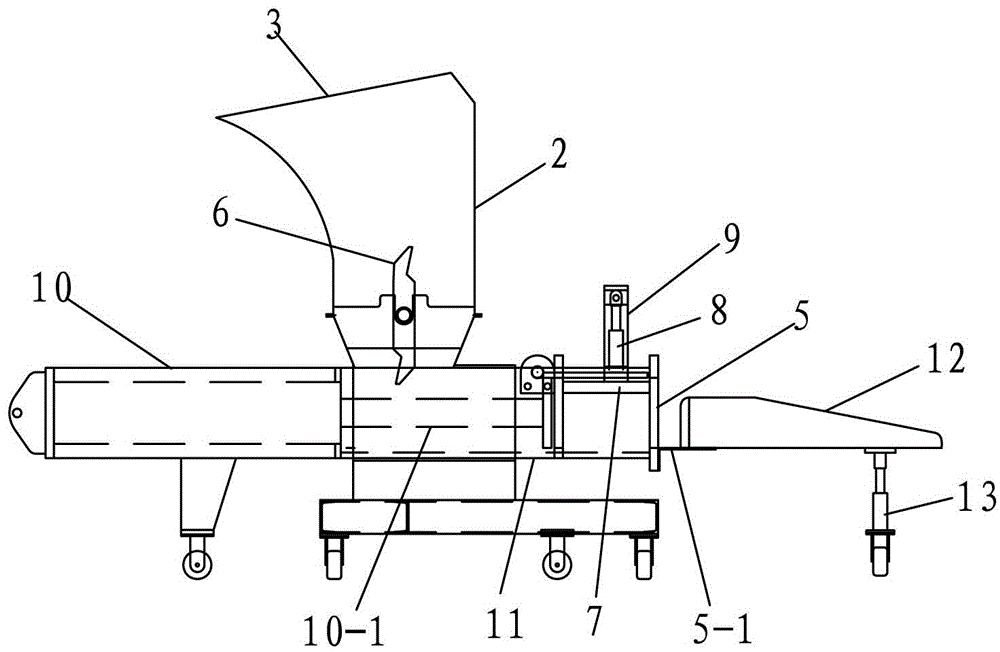

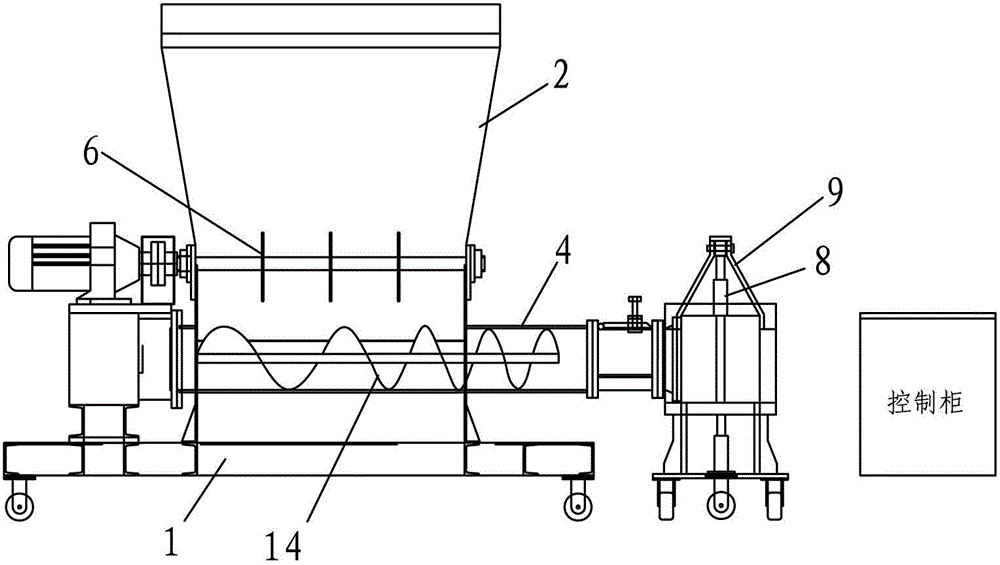

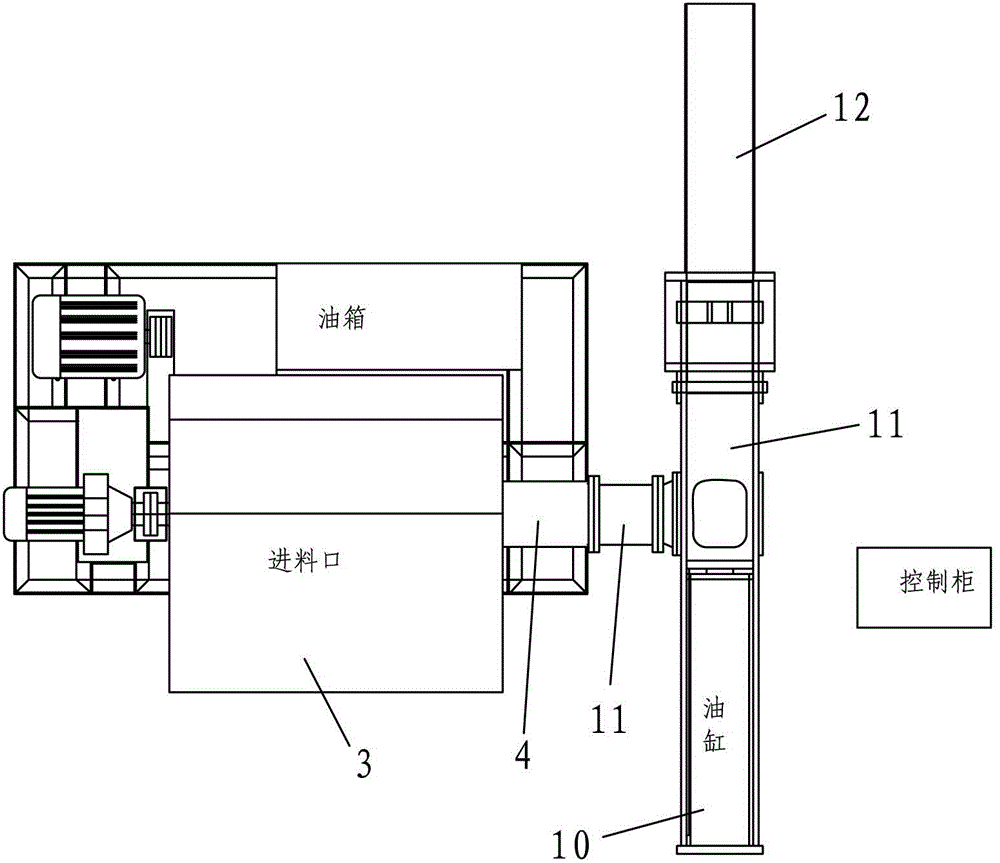

[0034] Such as Figures 1 to 7 , the hydraulic cold-press encryption machine of the present embodiment comprises: the machine case 2 and the frame 1 that are arranged up and down, the top of machine case 2 is provided with feed inlet 3, is provided with in the machine case 2 by the motor that distributes up and down. Driven crushing device 6 and feeding barrel 4, the feeding barrel 4 is provided with a screw rod 14 driven by a motor for sending the material crushed by the crushing device out of the barrel, and the feeding barrel 4 is coaxially arranged with the screw rod 14.

[0035] During specific implementation, the screw drive motor is connected to the screw drive through a gearbox, and the crushing motor is connected to the main shaft in the crushing device through a reduction motor.

[0036] The discharge port of the feeding cylinder 4 is connected to the material inlet on the cylinder side wall of a pressing cylinder 11, and one end of the pressing cylinder 11 is provid...

Embodiment 2

[0048] The working method of the hydraulic cold-press encryption machine in the above-mentioned embodiment 1, it comprises:

[0049] A. The material is crushed by the crushing device and sent to the feeding barrel, and the screw sends the material in the feeding barrel to the pressing barrel;

[0050] B. The piston of the hydraulic cylinder presses the material in the press cylinder from the material inlet of the press cylinder to the filler outlet of the press cylinder, and the filler outlet is closed with a baffle when it is initially working; when it is adjacent to the When the material density in the packing material outlet reaches a preset value or the pressure on the piston reaches a preset value, the baffle is opened, and the piston pushes out the material adjacent to the packing material outlet;

[0051] C. The screw continues to send the material in the feeding barrel into the pressing barrel, and the piston presses the material at the inlet of the pressing barrel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com