Inkjet printer

一种喷墨打印机、喷墨头的技术,应用在印刷等方向,能够解决无法耐受、保湿液喷出头难以批量生产、制造成本增加等问题,达到减少倒流的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, an inkjet printer to which the present invention is applied will be described with reference to the drawings.

[0035] (the whole frame)

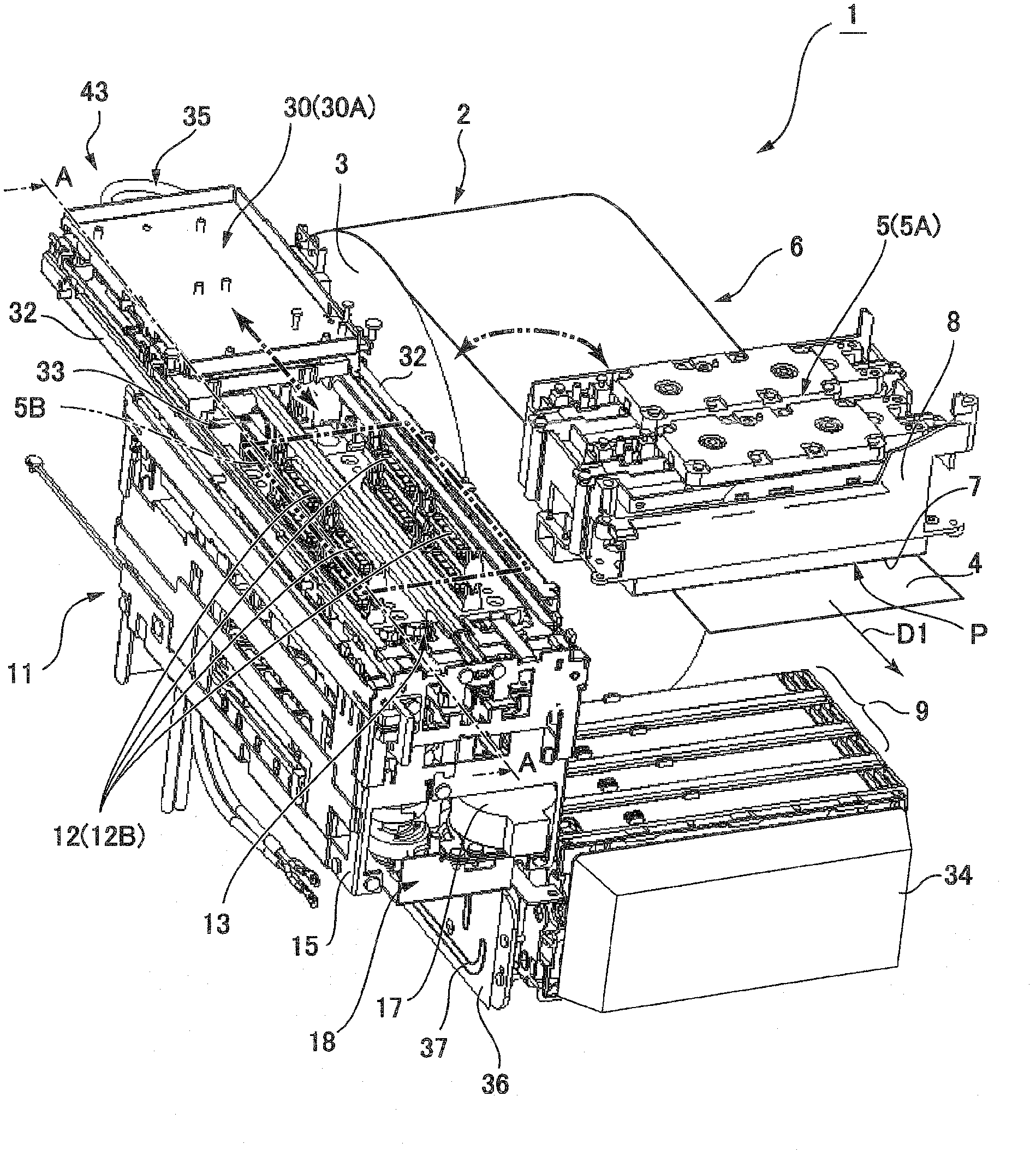

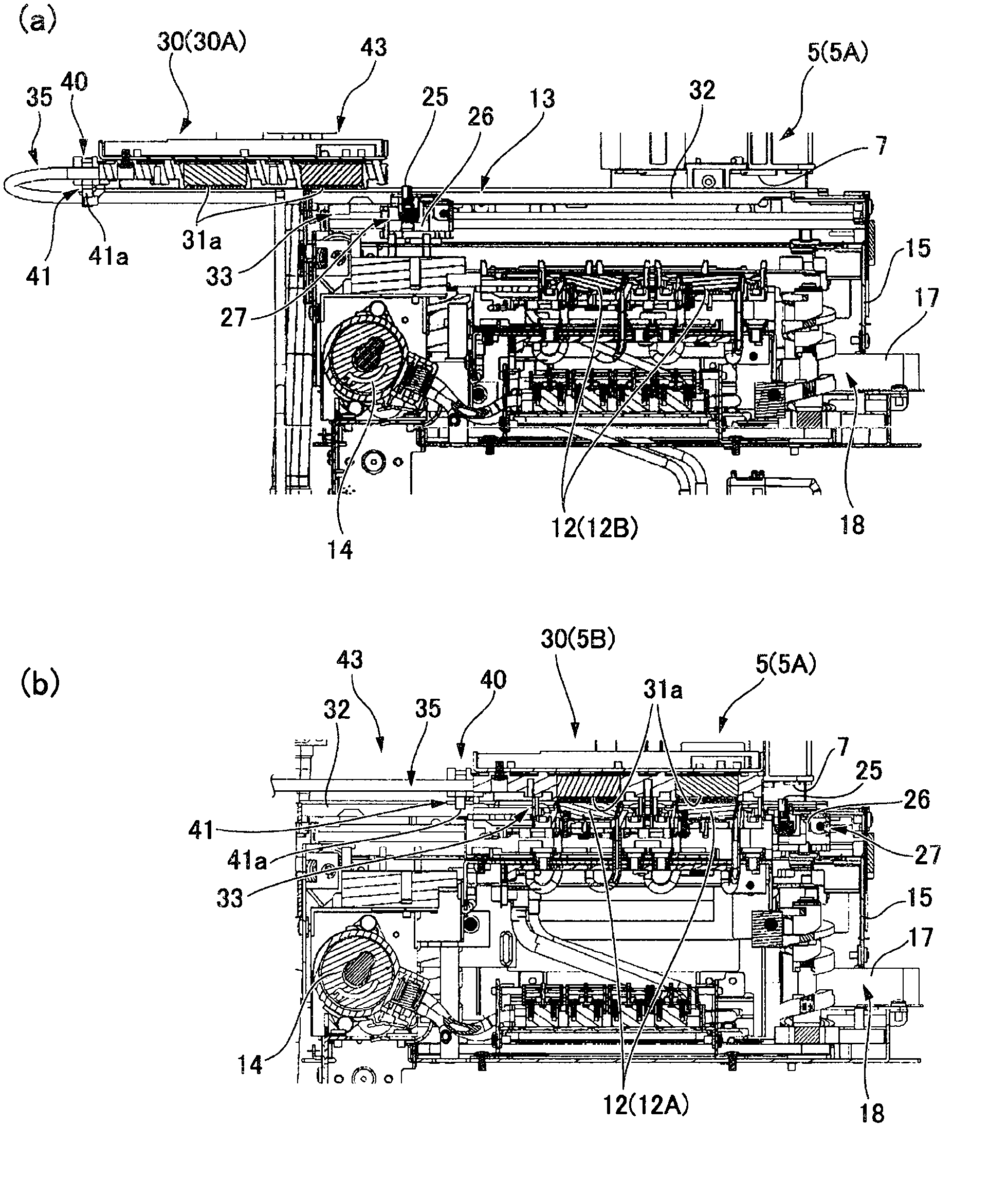

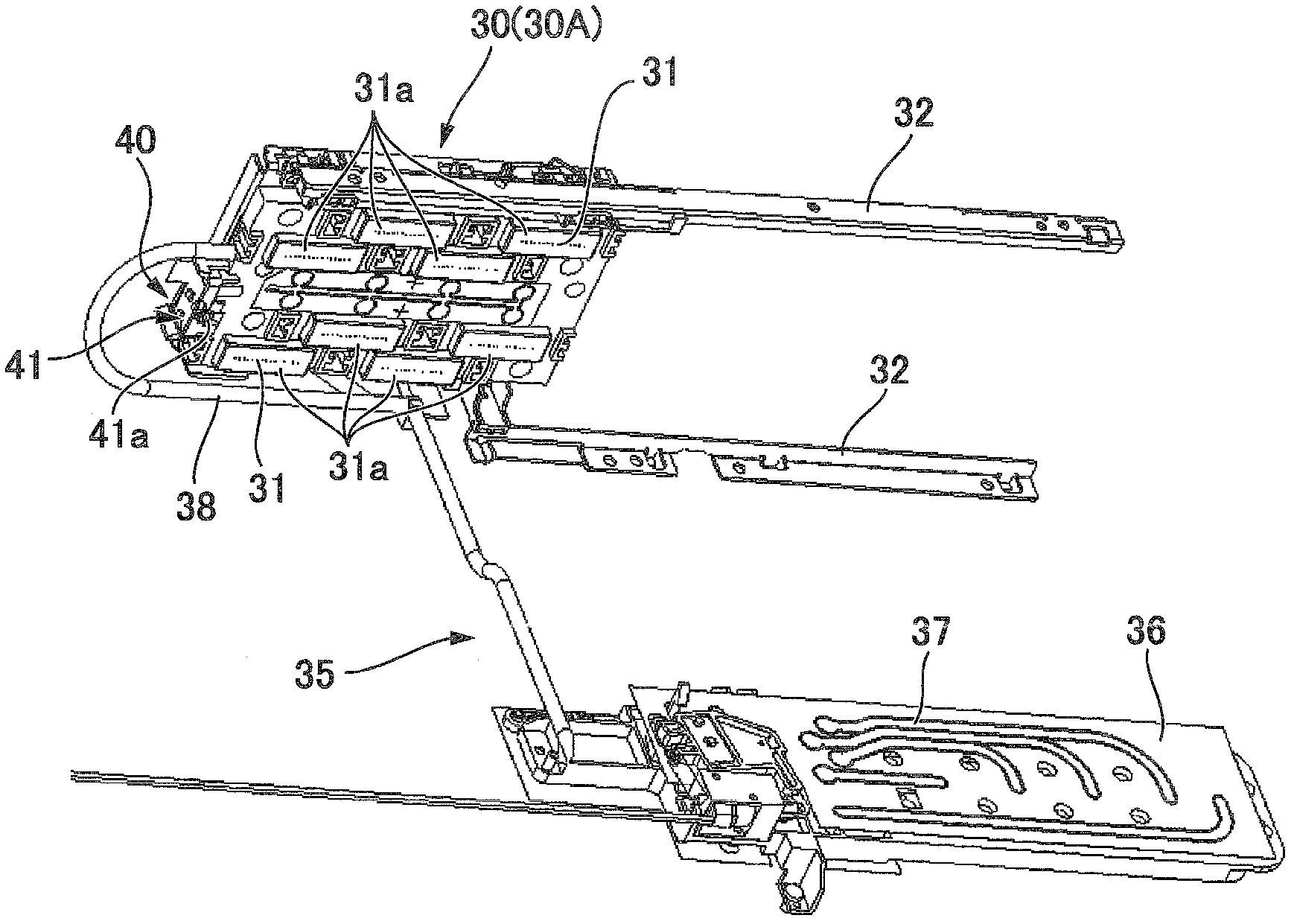

[0036] figure 1 It is a schematic perspective view showing main parts of the inkjet printer according to this embodiment, and shows a state where the printer case is removed. figure 2 yes figure 1 A sectional view at line A-A of figure 2 (a) shows the state in which the moisturizing liquid discharge head is arranged at the maintenance standby position, figure 2 (b) shows the state in which the moisturizing liquid discharge head is arranged at the maintenance position. image 3 It is a perspective view of the moisturizing liquid discharge head, moisturizing liquid supply path and guide rail seen from the lower side at the rear of the device.

[0037] Such as figure 1 As shown, the inkjet printer 1 conveys the recording paper 4 fed from the roll paper 3 in the conveying direction D1 toward the front of the device al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com