Sponge urban road in which comprehensive pipe rack is designed and road construction method

A technology of sponge city and comprehensive pipe gallery, applied in the field of construction engineering, can solve the problems of poor anti-seepage ability of pipe gallery, achieve the effect of reducing rainwater leakage, reducing water storage requirements, and improving water storage utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

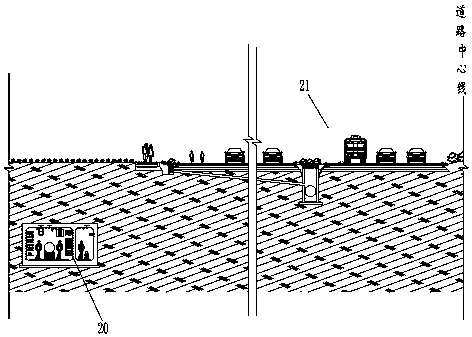

[0073] Example 1, such as Figure 1-5 Shown:

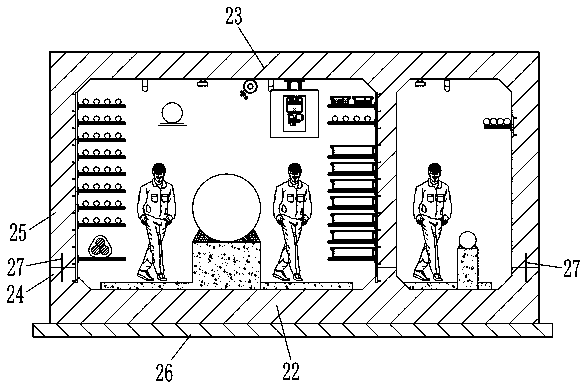

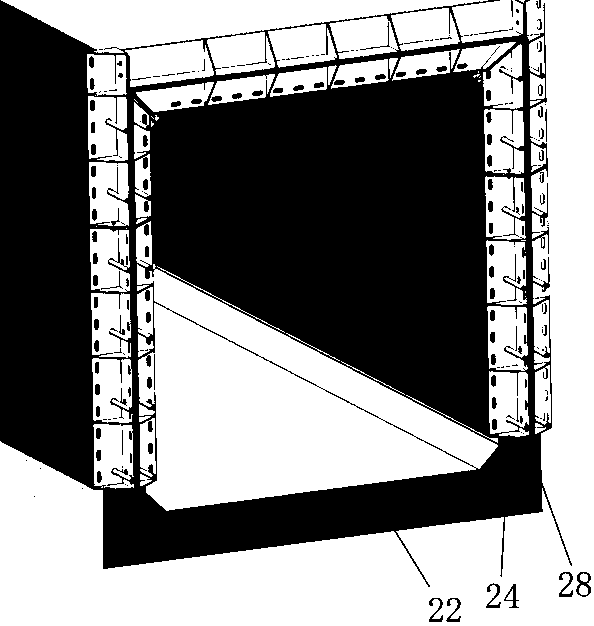

[0074] A sponge city road designed with a comprehensive pipe gallery, including a pipe gallery structure 20, the pipe gallery structure 20 includes a bottom plate 22, a side wall and a roof 23, and the side wall is vertically divided into an upper wall 25 located above and the lower wall 24 below the upper wall 25, the upper edge of the lower wall 24 is in contact with the lower edge of the upper wall 25, and the lower wall 24 is cast integrally with the bottom plate 22, so The upper wall body 25 and the top plate 23 are poured integrally.

[0075] In the cast-in-place construction of the pipe gallery, the current usual method is: first pour the bottom plate 22 in the trench of the excavated pipe gallery, and after the bottom plate 22 is hardened, arrange the formwork bracket 29 and the side wall formwork on the bottom plate 22, and then carry out For the pouring construction of the side wall, after the side wall is hardened, se...

Embodiment 2

[0082] Example 2, such as Figure 1-7 Shown:

[0083] A sponge city road designed with a comprehensive pipe gallery. On the basis of Example 1, the sponge city road also includes a road structure 21, and the pipe gallery structure 20 is located on the side of the road structure 21, and is connected to the The road structure 21 is parallel, and the road structure 21 includes: a roadway 1 and a first green space structure 2 arranged on the side of the roadway 1, and the first green space structure 2 is along the roadway 1. Set in the length direction, the first green space structure 2 includes a first green space foundation pit 3 excavated in parallel along the roadway 1, on the bottom and side walls of the first green space foundation pit 3, there are paved to prevent water seepage The leaky first anti-seepage layer 4, the first green land foundation pit 3 above the first anti-seepage layer 4 is backfilled with planting soil 5, and the first anti-seepage layer 4 is close to th...

Embodiment 3

[0104] Example 3, such as Figure 1-7 Shown:

[0105] A sponge city road designed with a comprehensive pipe gallery. On the basis of Embodiment 2, the first green space structure 2 also includes a number of first overflow wells 15 arranged along the length direction of the first green space structure 2, The level of the wellhead of the first overflow well 15 is lower than or equal to the level of the upper edge of the first anti-seepage layer 4 , and the adjacent first overflow wells 15 are connected by setting a drainage pipe 19 . In the scheme of the present application, by setting the first overflow well 15, when the rainfall is large, when the rainwater collected in the first green space structure 2 exceeds the wellhead of the first overflow well 15, it enters the first overflow well 15 and then It is discharged by the drainpipe 19 to prevent the rainwater in the first green land from pouring back onto the road surface of the roadway 1.

[0106] As a preferred technical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com