Automatic packaging equipment for realizing big/small end order arrangement of poultry eggs

An automatic packaging and size head technology, which is applied in the packaging of food, eggs, dairy products, etc., can solve the problem that the poultry egg grading operation and packaging operation cannot be realized together, and achieve good reliability, simple and complete structure, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to the drawings and embodiments.

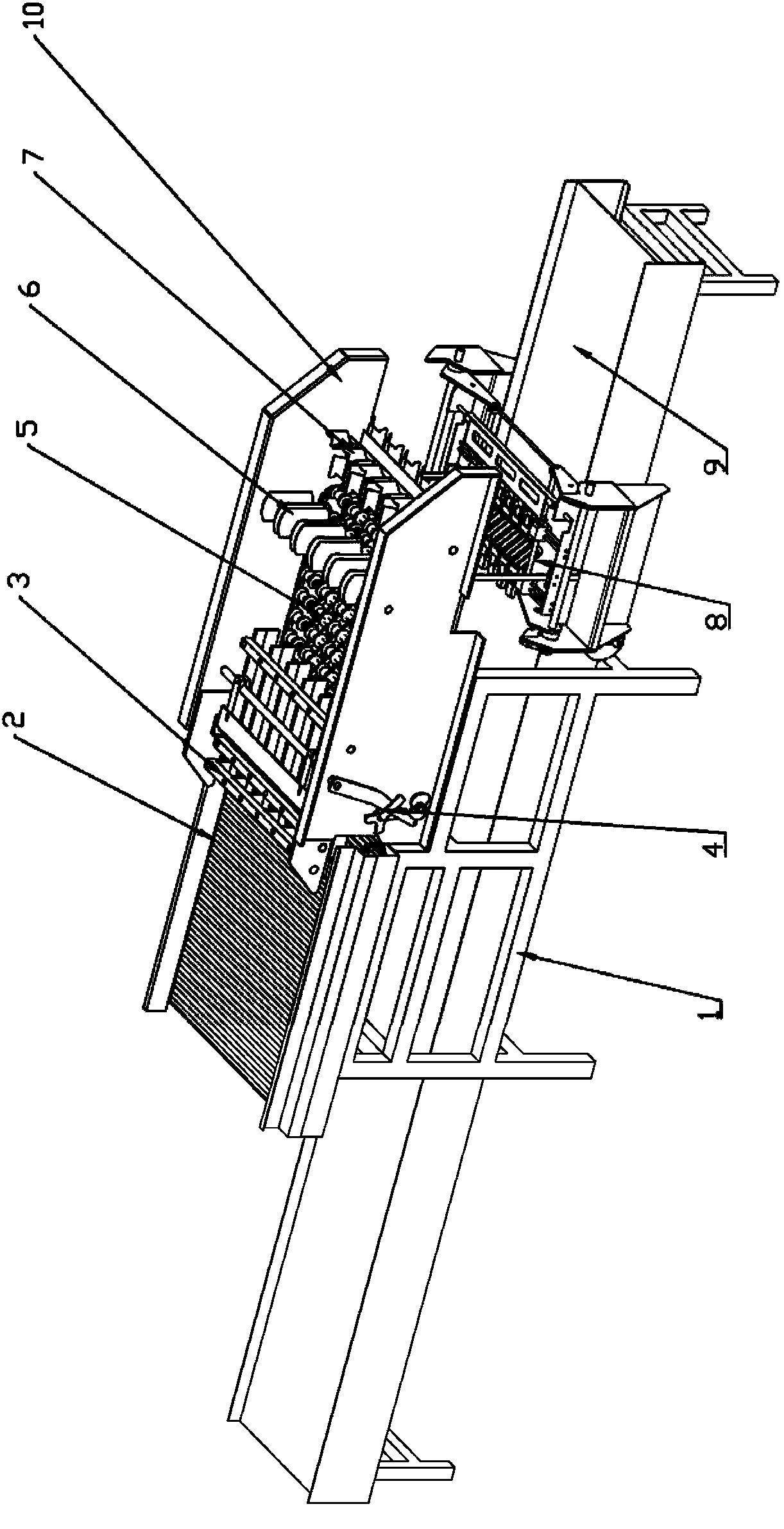

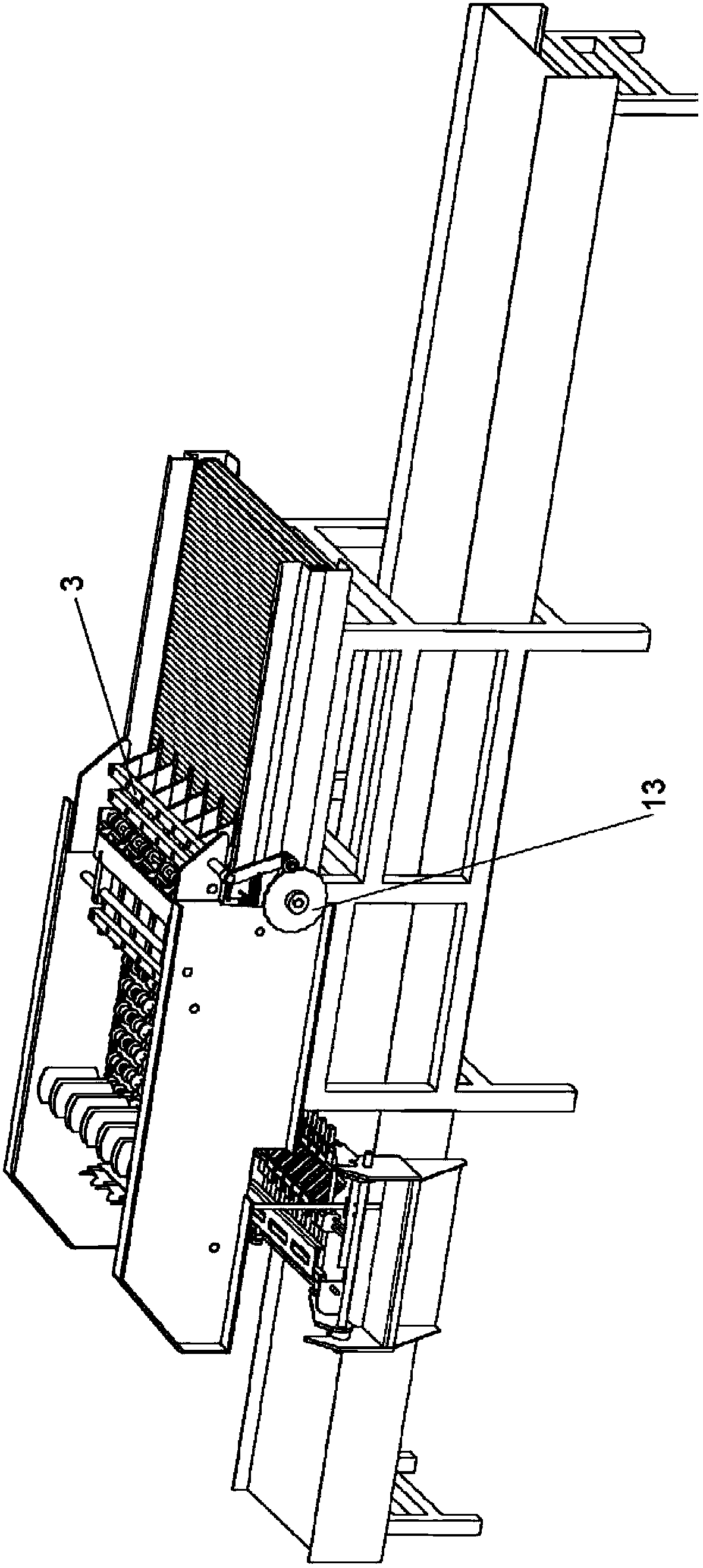

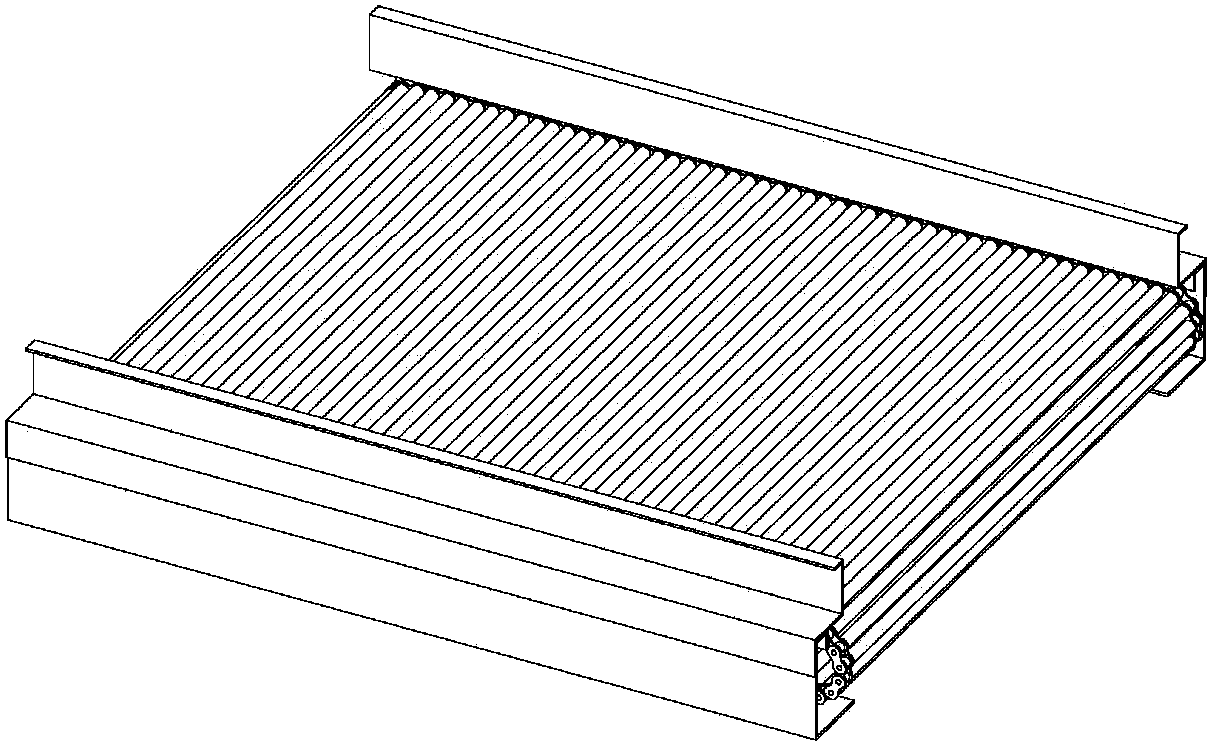

[0038] Such as figure 1 , figure 2 As shown, the present invention includes a frame 1, a feeding mechanism 2, a flow guide mechanism 3, a six-egg synchronization mechanism 4, a conveying mechanism 5, a large and small head reversing mechanism 6, a rotating guide mechanism 7, a supporting and placing mechanism 8, and egg tray conveying The platform 9 and two identical side fixing plates 10; the feeding mechanism 2 is installed on the conveying entrance of the rack 1, and the egg tray conveying platform 9 is installed on the bottom of the rack 1, on both sides of the rack 1 close to the conveying outlet. A side fixing plate 10 is fixed, a guide mechanism 3 is installed between the side fixing plates 10 on both sides toward the conveying inlet side, and the six-egg synchronization mechanism 4 is installed between the side fixing plates 10 on both sides above the guide mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com