Beautiful velvet manufacturing method

A manufacturing method and velvet technology, applied in the field of textile manufacturing, can solve the problems of no three-dimensional effect and lack of brightness of flannelette fabrics, and achieve the effect of improving the three-dimensional effect and brightness, simple process, maintaining softness and comfortable hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] The invention provides a production method of velvet, which breaks through the traditional production process of velvet fabric, and makes modifications in the post-treatment process, so that the produced velvet fabric has the characteristics of three-dimensionality and brightness.

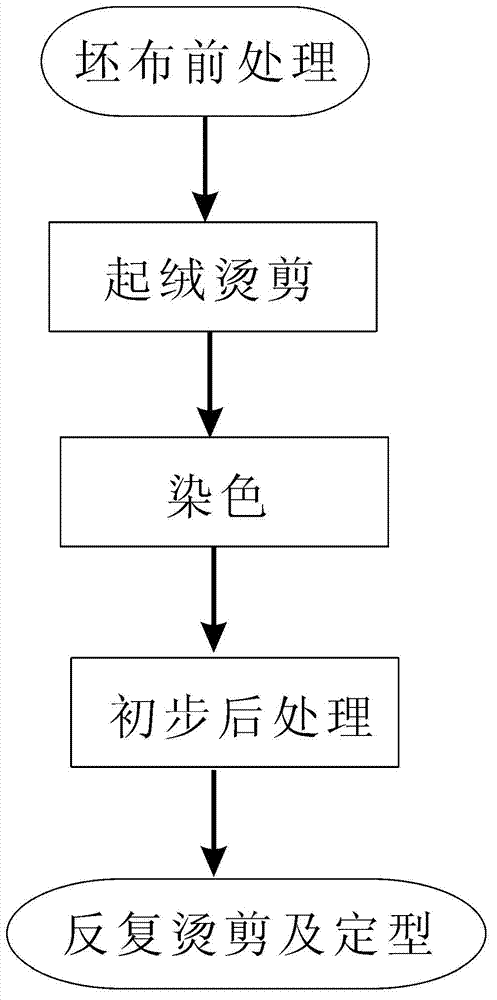

[0017] Such as figure 1 Shown, is the technological process schematic diagram of beautiful velvet of the present invention. It can be seen from the figure that the process steps mainly include the pre-treatment of gray cloth, raising and ironing, dyeing, preliminary post-processing, repeated ironing and shaping.

[0018] Below just introduce its production and manufacturing process in detail from the specific process step by step of this flannelette production, so that the technical solution of the present invention is easier to understand and grasp.

[0019] The mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com