Lifting construction method for arch rib segments of steel box handle-basket arch bridge

A technology of basket arch bridge and hoisting method, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of wasteful equipment configuration and low efficiency, and achieve the effects of improving construction efficiency, reducing scale, and reducing instantaneous risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

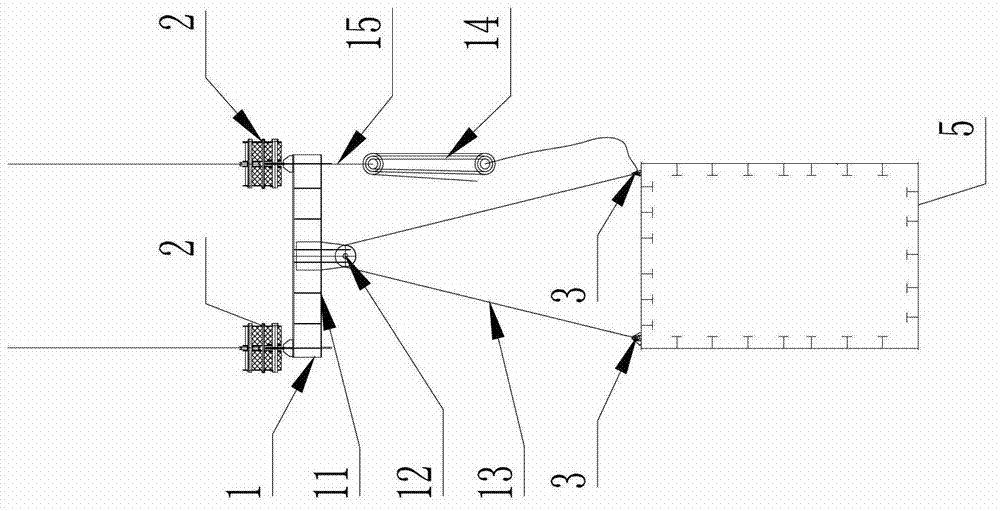

[0025] The hoisting method of the arch rib segment of the steel box basket arch bridge provided by Fangming is realized by using two sets of horizontally adjustable spreaders. The present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The hoisting construction method of the arch rib segment of the steel box basket arch bridge provided by the present invention comprises the following steps:

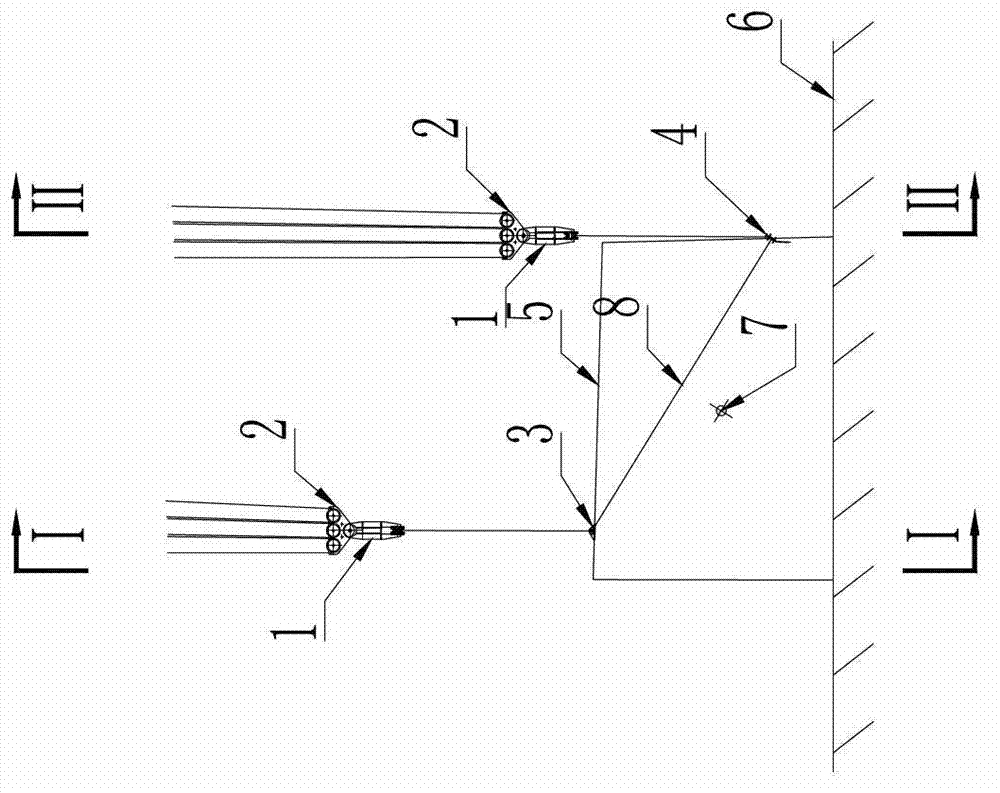

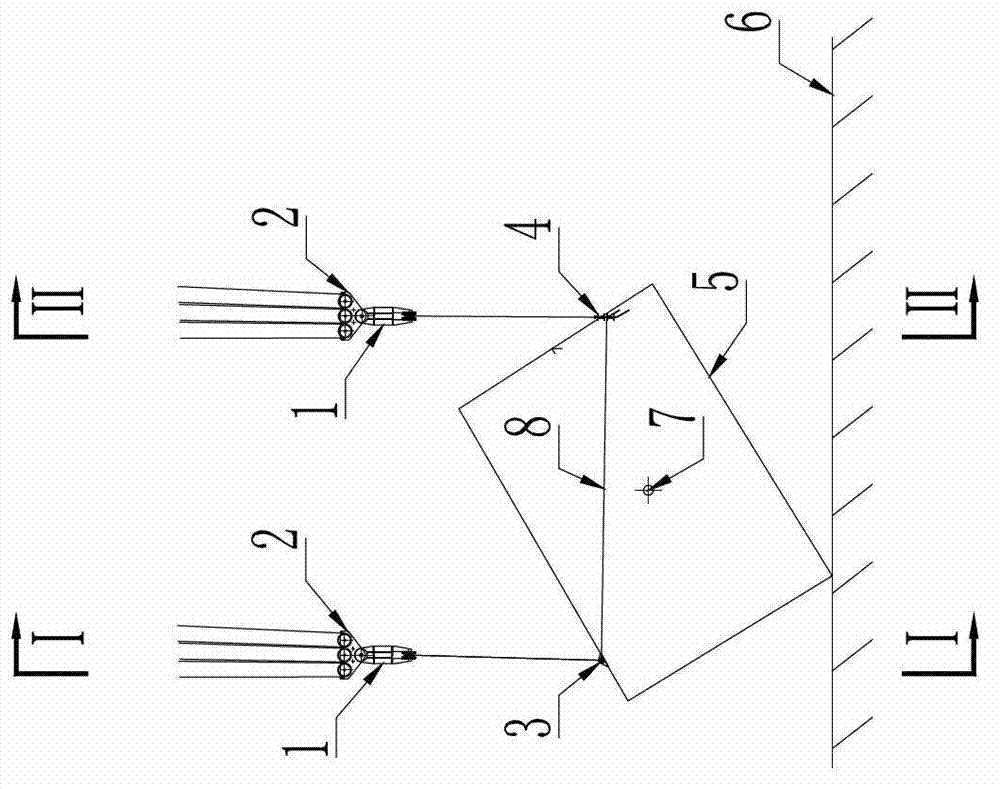

[0027] (1) Hoisting preparations, set the front and rear two sets of lifting points 4, 3 on the arch rib segment 5, and connect with the front and rear two sets of horizontally adjustable spreaders 1 respectively.

[0028] See figure 1 , 3 , 4. The rear set of lifting points 3 is set on the top plate of the arch rib segment 5, and the front set of lifting points 4 is set on the inner side of the web at the opening section of the arch rib segment 5. The front and rear sets of lifting points include two lifting points point, and the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com