Wind power generation and wind power air compression dual-purpose machine with automatic speed regulation function

A technology of automatic speed regulation and air compression, which is applied to wind turbine components, wind turbines, wind turbines that are consistent with the wind direction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

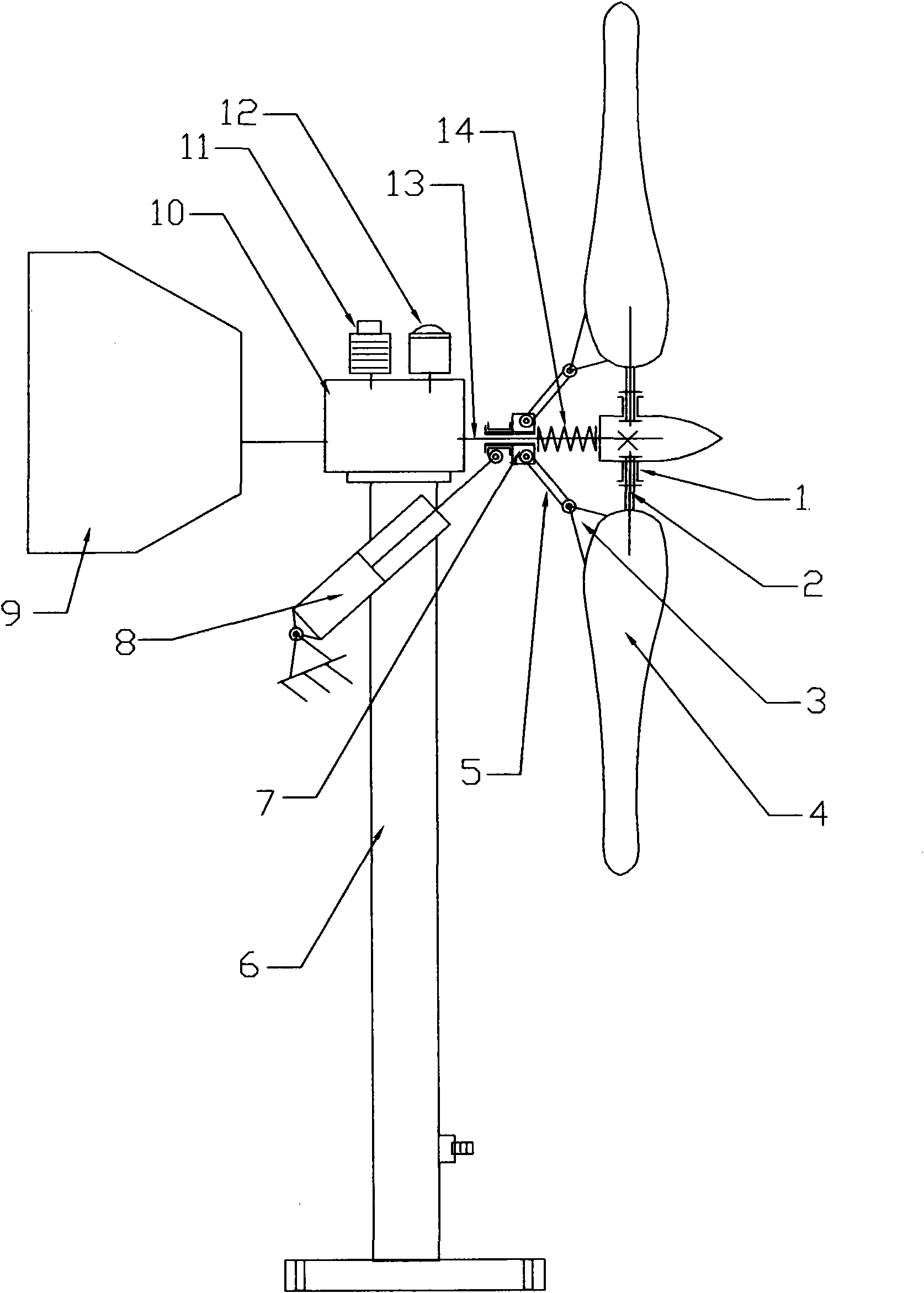

[0009] figure 1 As shown, the components for wind power generation are composed of fan blade 4, fan blade shaft 2, fan blade flange 1, adjustment arm 3, and power shaft 13; fan blade shaft 2 is connected to fan blade flange 1 through a radial bearing, and fan blade 4 can be wound When the shaft rotates, the power shaft 13 is equipped with an axially slidable blade angle adjustment sleeve 7, and the push rod of the cylinder 8 installed on the frame is connected with the adjustment sleeve 7, and the connecting rod 5 is used between the adjustment sleeve 7 and the adjustment arm 3. connection, the power shaft 13 is equipped with a preload spring 14, and the preload spring 14 is installed between the adjustment sleeve 7 and the fan blade flange 1. Under normal conditions, the adjustment sleeve 7 is pushed by the preload spring 14, and the fan blade is pulled by the connecting rod 5 Adjust the arm 3 so that the wind-receiving surface of the fan blade 4 and the wind direction have a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com