Vertical shaft wind scoop type universal windmill

A vertical axis and wind bucket technology, applied in the field of "vertical axis wind bucket type universal windmills, can solve the problems of low wind energy utilization efficiency, inability to obtain natural strengthening pressure, etc., and achieve the effect of improving utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

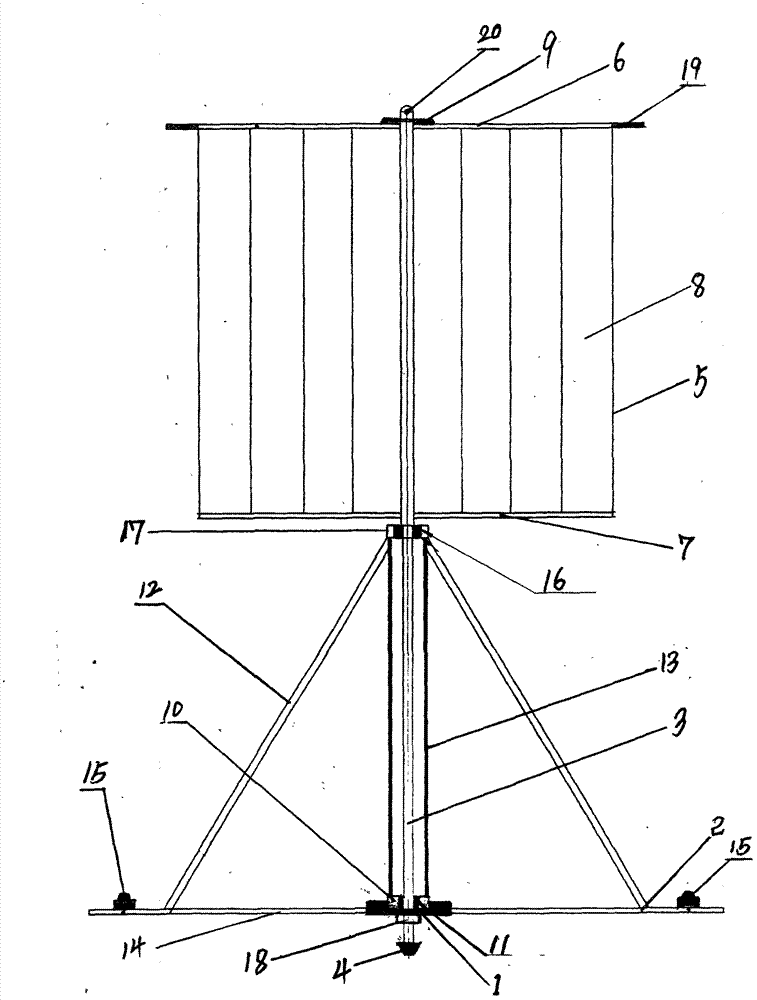

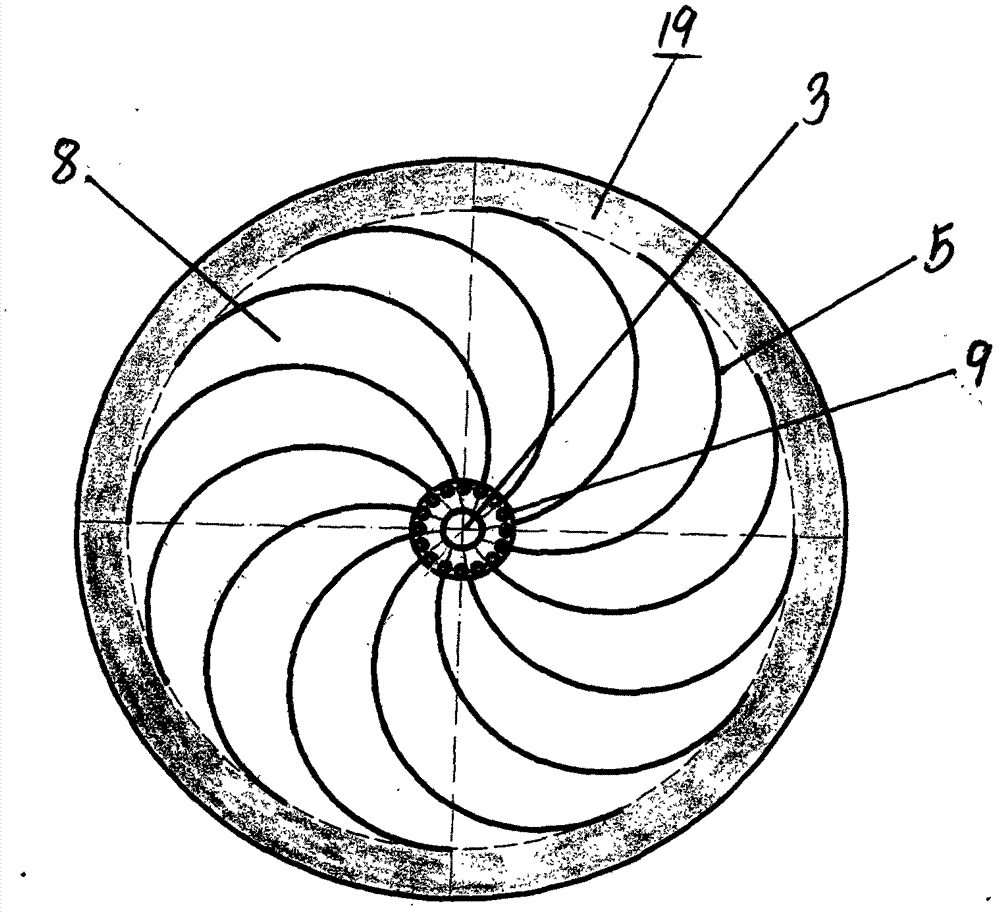

[0011] The "vertical axis wind bucket type universal windmill" is composed of a base 1, a bracket 2, a vertical shaft 3, a power output device 4, an upper blocking cover 6 and a lower blocking cover 7. In order to make the windmill run smoothly, multiple arcs The blades 5 are correspondingly arranged in the same direction between the upper block cover 6 and the lower block cover 7 to form a plurality of wind buckets 8 . The arc blades 5 are provided with at least one pair, preferably two to sixteen pairs, and the wind bucket 8 consists of two adjacent arc blades 5 and corresponding parts of the upper block cover 6 and the lower block cover 7. When a pair When the above arc blades 5, the wind bucket 8 should be a "horn-shaped" pointed bottom sealing shape, and the bottom points all sit on the vertical shaft bar 3. In order to adjust the wind pressure in the wind bucket 8 to control the speed or output power of the windmill, a wind pressure adjustment window 9 should be set on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com