Defoaming device for photoresist

A technology of photoresist and photoresist, which is applied in the direction of photoplate making process coating equipment, etc., can solve the problem of waste of photoresist cost, and achieve the effect of avoiding air bubbles in the pipeline and saving photoresist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

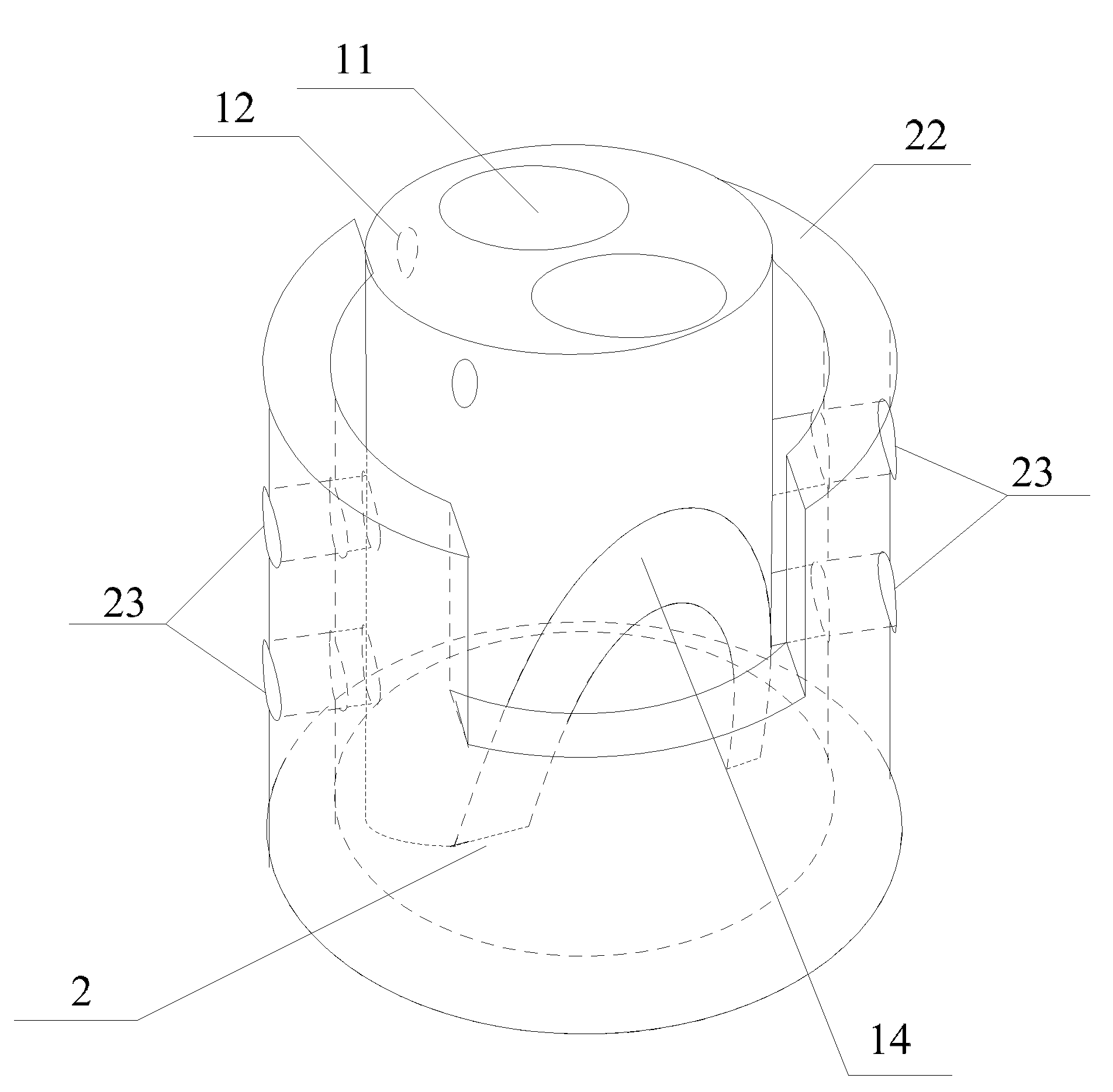

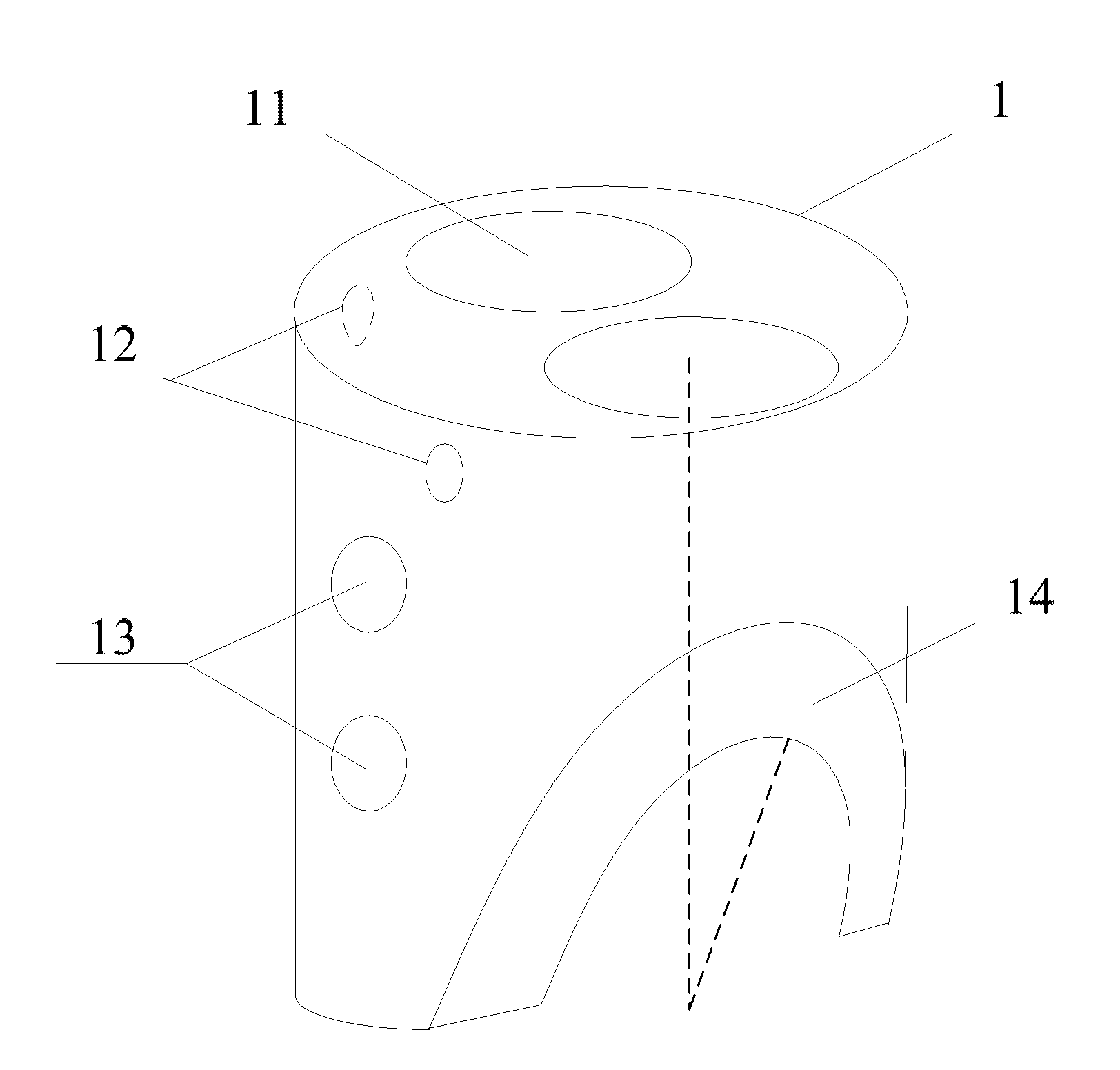

[0032] As mentioned in the background technology section, when replacing the photoresist bottle, air will enter the photoresist pipeline, and after being inserted into the new photoresist bottle, air bubbles will be generated. A large amount of photoresist, thus causing waste of photoresist, the inventor found that the reason for the occurrence of bubbles is that after the photoresist pipeline is taken out from the current photoresist bottle, the photoresist in the pipeline is unbalanced in force, resulting in The photoresist flows out of the tube. In other words, when the photoresist tube is inserted into the photoresist bottle, the gravity of the photoresist will be offset by the pressure in the photoresist bottle, and the photoresist tube is exposed. When in the air, due to the lack of pressure opposite to the direction of the photoresist's own gravity, the photoresist must drop from the photoresist pipeline due to its own gravity, so that air enters the pipeline.

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com