Wiper blade, in particular for glass of a motor vehicle, and method for producing a wiper blade

A technology for wiper blades and motor vehicles, which is used in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of high bending force and shear force, high additional cost of wiper blades, etc., and achieve the effect of reducing welding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

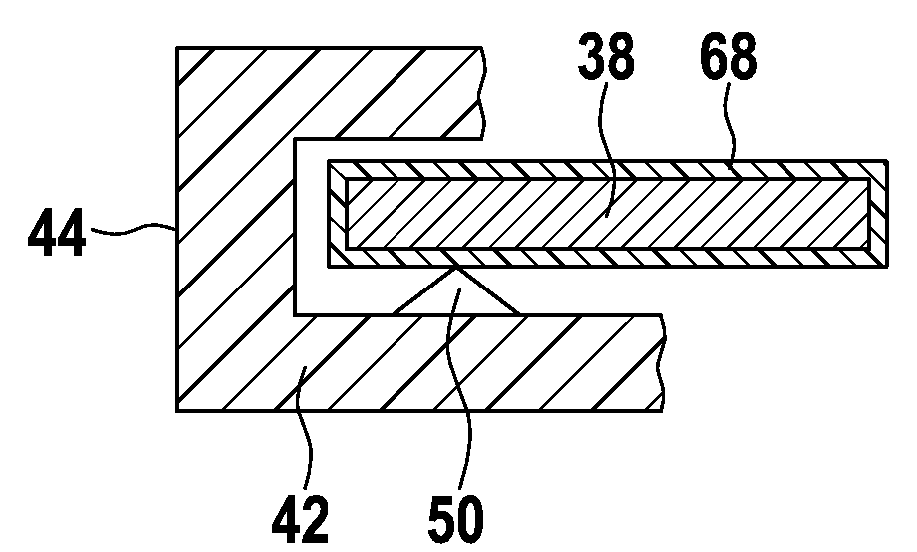

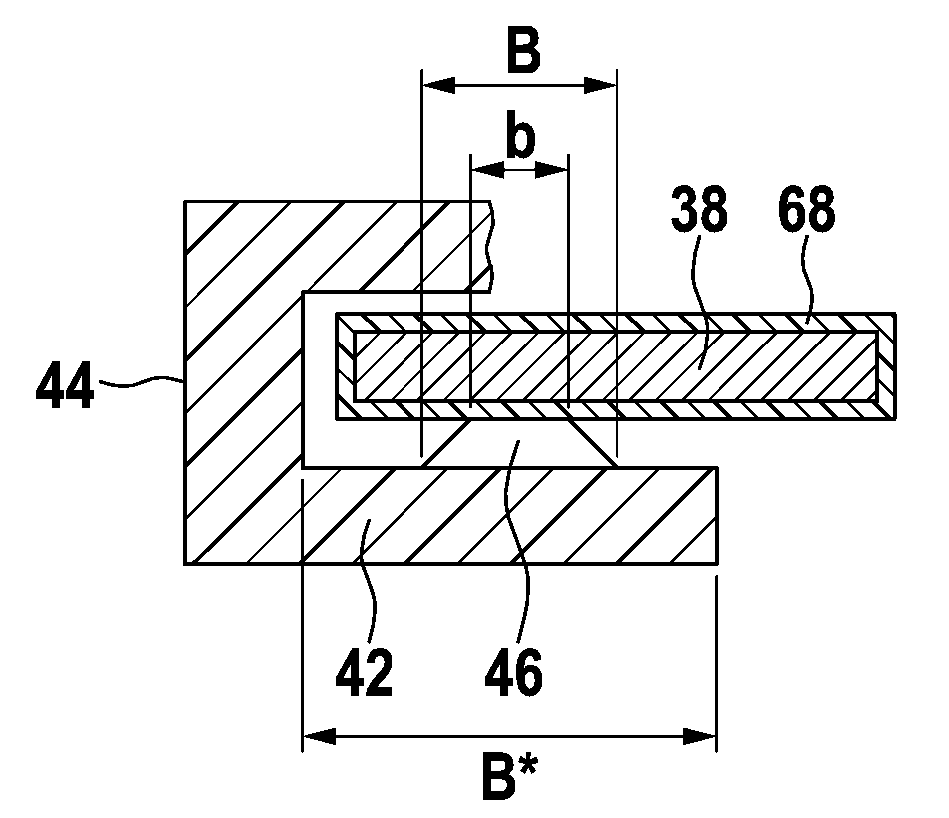

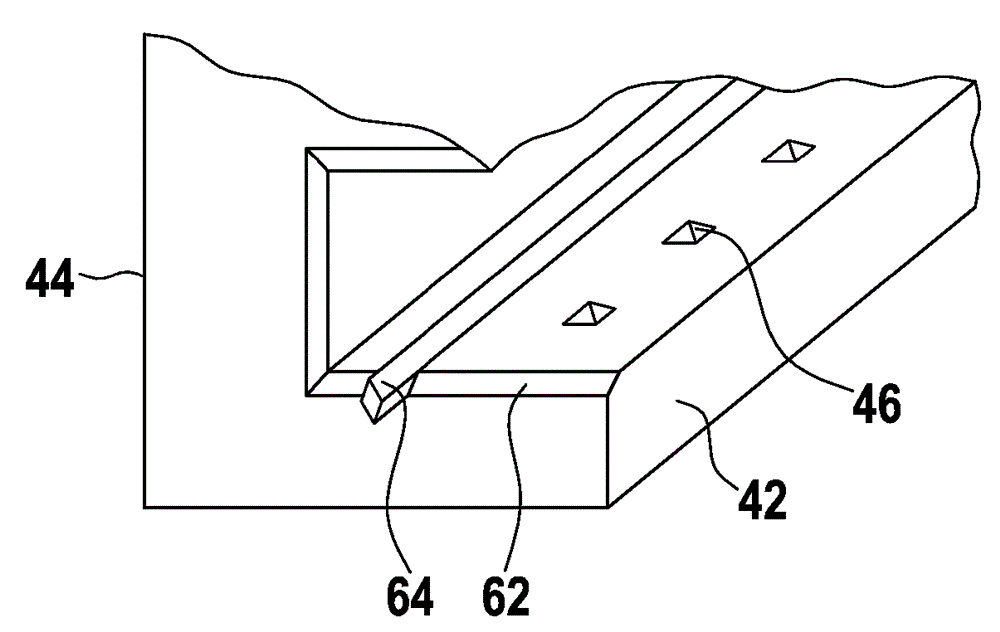

[0027] exist figure 1 The wiper blade 10 shown in has a strip-shaped elongated spring-elastic carrier element 12 ( figure 1 and 2 ), an elongated rubber-elastic wiper strip 14 is fastened parallel to the longitudinal axis on the lower, concave strip side facing the glass of the carrier element. On the upper side of the carrier element 12 , which can also be referred to as a spring rail, protruding away from the glass, in the middle section of the carrier element is arranged a connecting device 15 on the wiper blade side, by means of which connection The device 15 can articulate the wiper blade 10 with the figure 1 The wiper arm 16 outlined in dot-dash line is releasably connected. the edge figure 1 The wiper arm 16 driven to swivel in the direction of the double arrow 18 in the direction of the arrow 24 faces the glass to be wiped—for example, the windshield of a motor vehicle is loaded—the surface of the windshield figure 1 Outlined by dotted line 22 in . Since the line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com