Preparation and application of sodium alginate pervaporation hybrid membrane

A technology of pervaporation and sodium alginate, applied in the field of separation membrane, can solve the problems of poor anti-pollution, broken hollow fiber membrane, insufficient mechanical strength of pure sodium alginate membrane, etc., and achieve good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

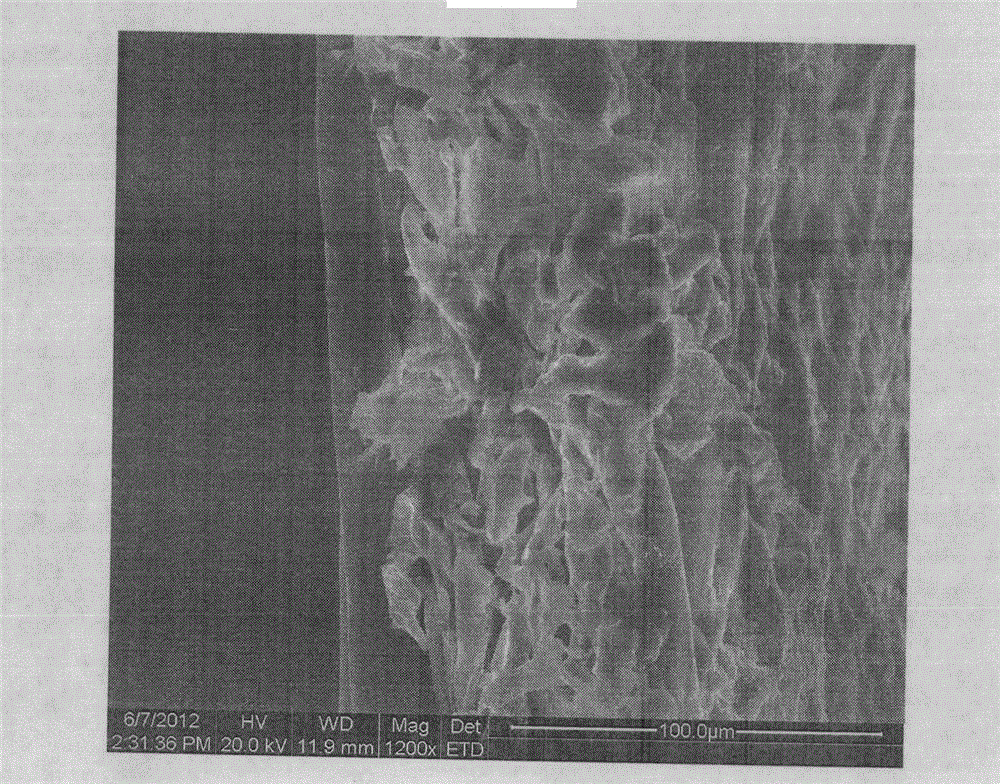

Image

Examples

Embodiment 1

[0027] Weigh 4g of sodium alginate and dissolve it in 46g of distilled water, stir at 70°C until the sodium alginate is completely dissolved, weigh 0.08g of phosphotungstic acid and 50g of distilled water, dissolve it for 30min at an ultrasonic frequency of 50KHz, and then slowly add it to the seaweed In the sodium alginate solution, continue to stir for 24 hours, adjust the pH between 6-8 with alkali, and maintain the mass percentage of sodium alginate in the solution at 4%. The solution was filtered through a sand core funnel and allowed to stand for defoaming. Put the non-woven fabric in a polyacrylonitrile solution with a mass fraction of 2% for 30 minutes, put it in a water bath at 30° C. and 60° C. for 1-2 hours, and dry it at room temperature. Apply the prepared casting solution evenly on the surface of the base film with a doctor knife, and dry it in vacuum at 60-70°C for 24 hours, then place the hybrid film in the cross-linking solution for cross-linking reaction, the...

Embodiment 2

[0033] As in the process steps of Example 1, wherein only the amount of phosphotungstic acid is changed to 0.16g, the sodium alginate organic-inorganic hybrid membrane of the present invention is made, and its performance is shown in the following table:

[0034] Feed liquid concentration (methanol WT%)

Embodiment 3

[0036] As in the process steps of Example 1, wherein only the amount of phosphotungstic acid is changed to 0.24g, the sodium alginate organic-inorganic hybrid membrane of the present invention is made, and its performance is shown in the following table:

[0037] Feed liquid concentration (methanol wt%)

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap