Board rolling device

A technology of plate and work roll, applied in the direction of metal rolling, metal rolling, metal rolling racks, etc., can solve the problems of high manufacturing cost and increased structural complexity, and achieve the effect of reducing manufacturing cost and simplifying the structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The plate rolling device involved in the present invention will be further described below with reference to the accompanying drawings.

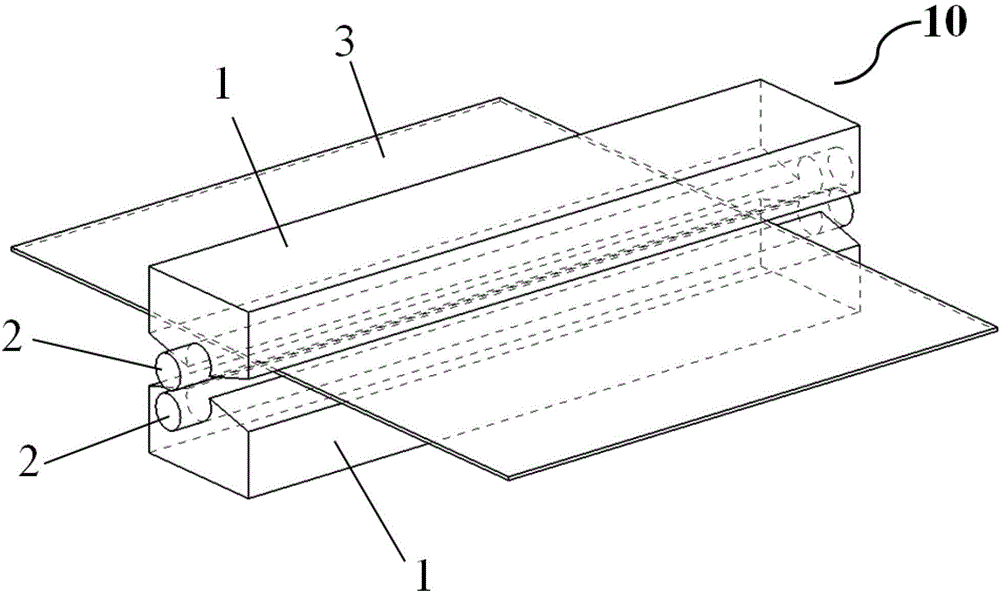

[0024] figure 1 It is a schematic diagram of the plate rolling apparatus 10 which concerns on one Embodiment of this invention.

[0025] The plate rolling device 10 includes a work roll 2 for rolling a plate 3, a support body 1 for supporting and limiting the work roll 2, and a driving mechanism (not shown) for driving the work roll, The work roll 2 includes an upper work roll and a lower work roll; wherein, the rigidity of the support body 1 is equal to more than 10 times the rigidity of the work roll 2 , and the contact length between the support body 11 and the work roll 2 is greater than the width of the plate 3 .

[0026] In the plate rolling device 10 , the section of the working roll 2 is small, and the section of the supporting body 1 is much larger than that of the working roll 2 , so its rigidity is much greater than that o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com