A safety interlock system for locomotive maintenance work

A technology of safety interlocking and locomotive maintenance, applied in railway signal and safety, transportation center control system, railway car body parts, etc. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

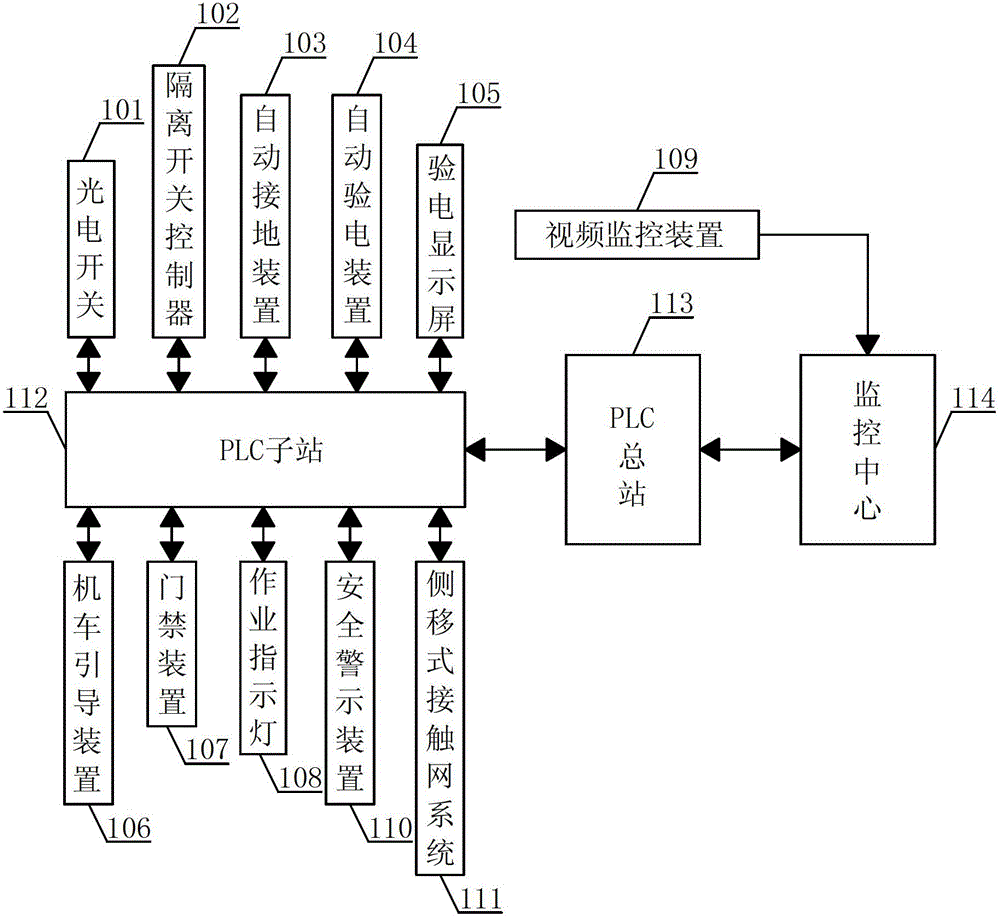

[0031] Please refer to figure 1 As shown, the locomotive maintenance operation safety interlock system in this embodiment includes: photoelectric switch 101, isolating switch controller 102, automatic grounding device 103, automatic electric inspection device 104, electric inspection display screen 105, locomotive guidance device 106, access control device 107 , operation indicator light 108 , video monitoring device 109 , safety warning device 110 , side-moving catenary system 111 , PLC substation 112 , PLC main station 113 and monitoring center 114 .

[0032] The photoelectric switch 101 is connected with the PLC substation 112 for detecting whether the maintenance station is occupied.

[0033] When an locomotive applies to enter a maintenance platform o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com