Battery loading vehicle

A technology for battery loading and loading vehicles, applied in the directions of transportation, packaging, roller tracks, etc., can solve the problems of increasing battery safety, lack of transplanting vehicles and equipment, and cumbersome operation, so as to improve transfer safety, ensure mobile safety, The effect of preventing tipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

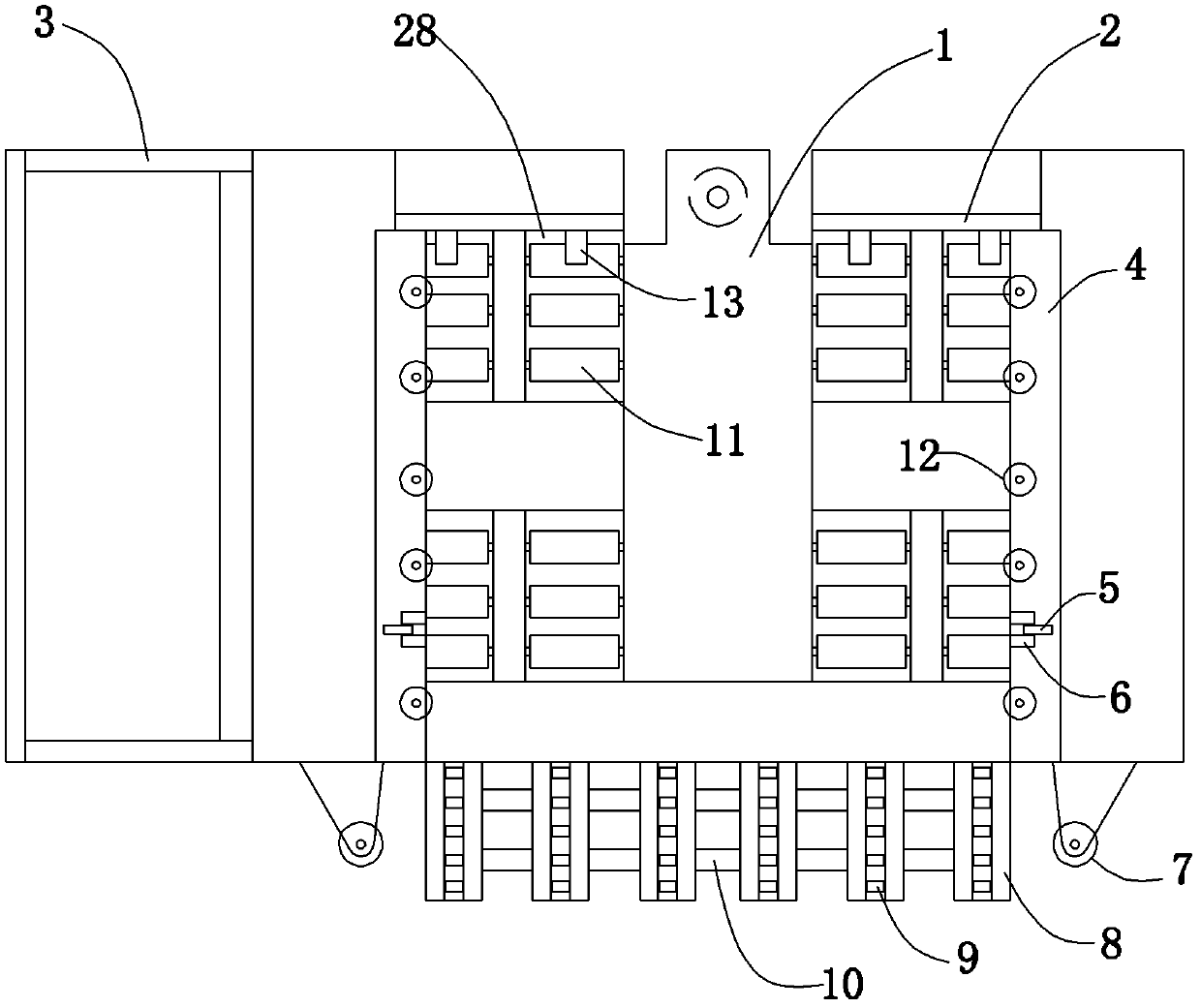

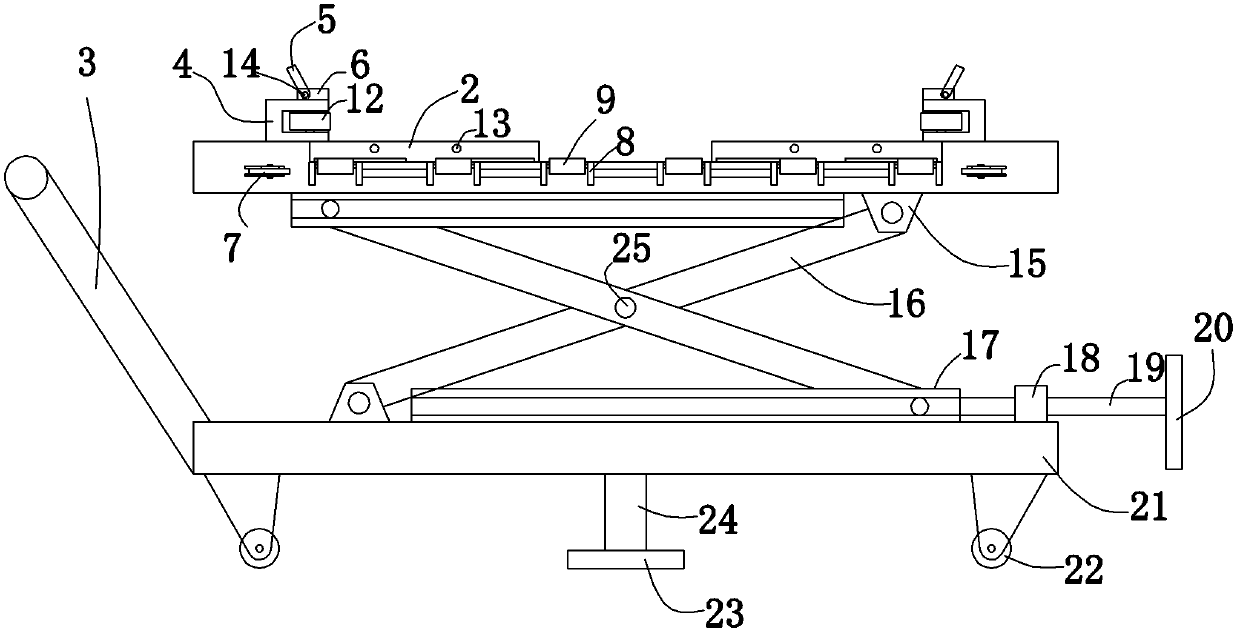

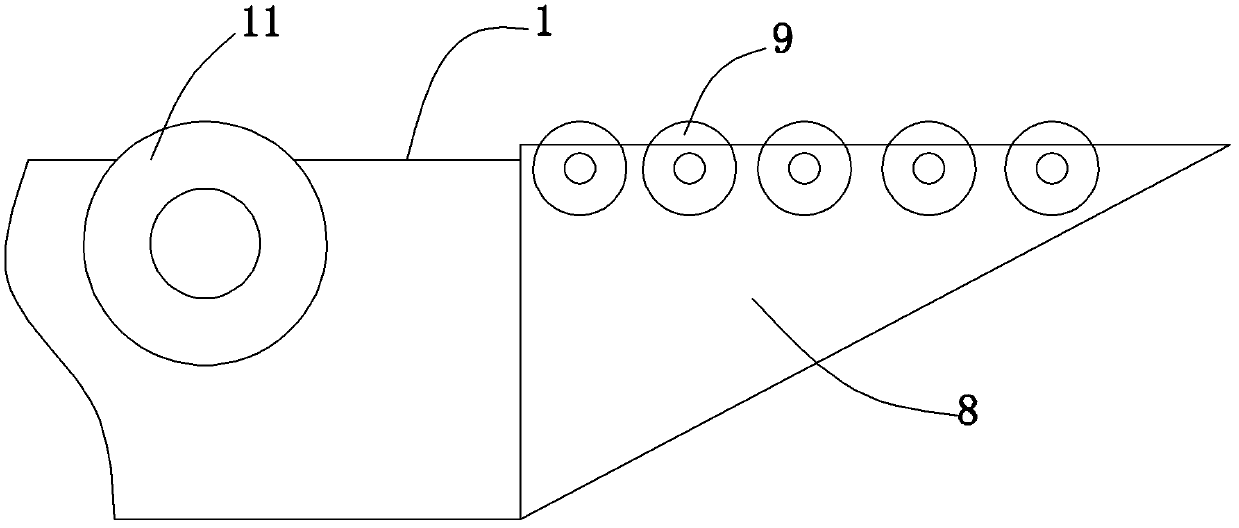

[0025] Embodiment 1: a battery loading vehicle (see attached figure 1 attached figure 2 ), the frame of the loading vehicle includes a lifting frame and a bearing platform 1 arranged above the lifting frame, and four traveling wheels 22 are arranged at the bottom of the lifting frame.

[0026]The elevating frame comprises a frame bottom 21, two groups of frame bodies 16 hinged in an X shape through hinge shafts 25 arranged on the frame bottom, and a drive mechanism that drives the frame body to rotate around the hinged position. There are four walking wheels arranged on the bottom surface of the frame. An inclined handle 3 is fixed on the side of the frame bottom. Two hinge seats 15 and two slide rails 17 are fixed on the chassis, and the slide rails are C-shaped, and the C-shaped openings of the two slide rails are opposite. Two of the frame bodies are quadrangular in total, one is a small frame body, and the other is a large frame body, and the maximum width of the small...

Embodiment 2

[0030] Embodiment 2: A battery loading vehicle, the bridging portion is fixed to the side of the carrying platform, the upper plane formed by the second rollers on the bridging frame is inclined to the upper plane formed by the first rollers, and the second rollers are formed The edge of the upper plane near the side of the loading vehicle is abutted with the edge of the upper plane formed by the first roller near the side of the loading vehicle. Refer to Example 1 for all the other structures.

Embodiment 3

[0031] Embodiment 3: a battery loading vehicle (see attached Figure 4 ), the side of the bearing platform is fixed with a support 26, and the beam of the bridging part is hinged to the support through the rotating shaft 27, the beam body is rectangular, and the end of the beam is a triangular structure. Refer to Example 1 for all the other structures.

[0032] Transfer the loading vehicle to the equipment with battery replacement, turn the handle 20, raise the load-carrying platform, and after rising to a suitable height, connect the end of the bridging part to the opening of the battery installation part, and the side anti-collision wheel Hold the side of the device, adjust the position, and then rotate the stud, the brake disc is against the ground. Pull the storage battery out from the equipment and transfer it to the carrying platform close to the limit column 13, then turn over the limit block 5 to block the storage battery. Then loosen the studs, raise the brake disc,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com