Inner drum for washing machine and washing machine with same

A washing machine and inner tub technology, applied in the field of washing machines, can solve problems such as loud noise, affecting the performance of washing machines, wasting electric energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The inner tub for the washing machine and the washing machine provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

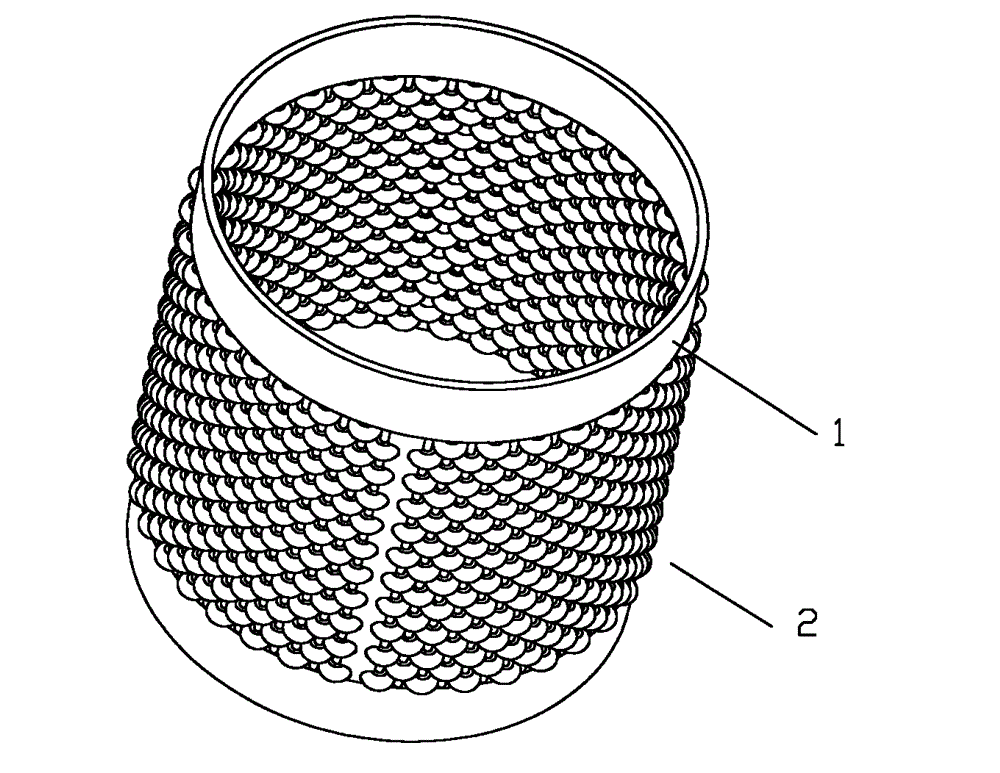

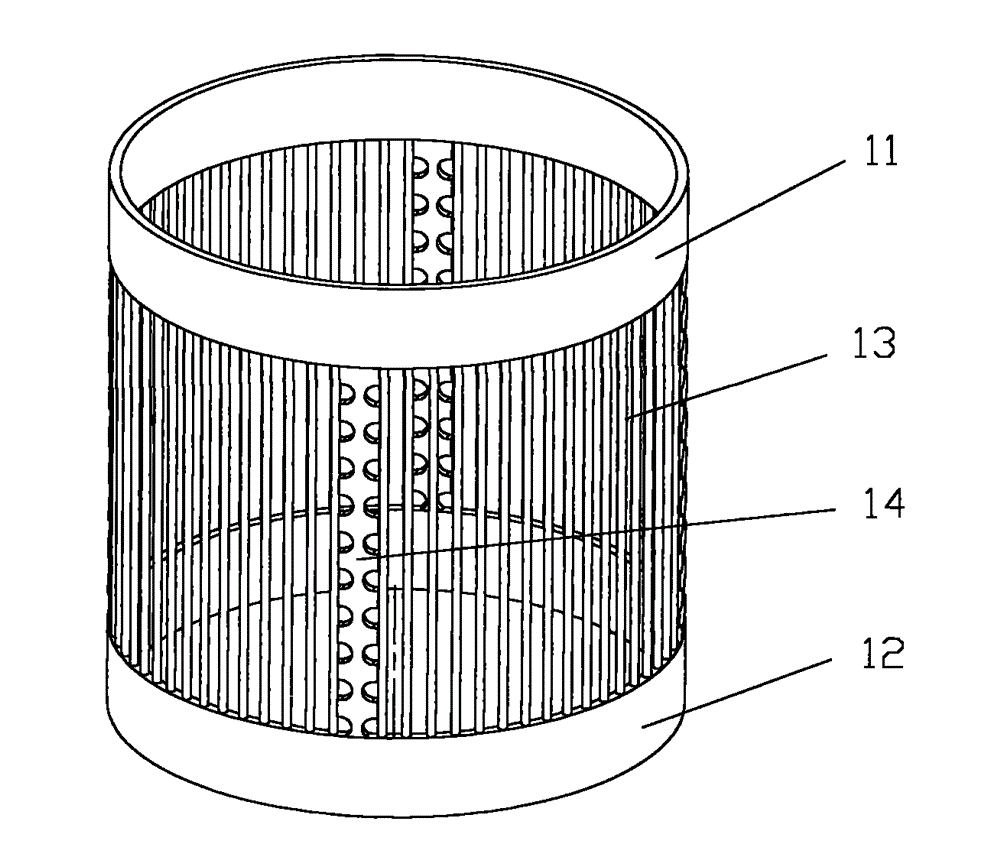

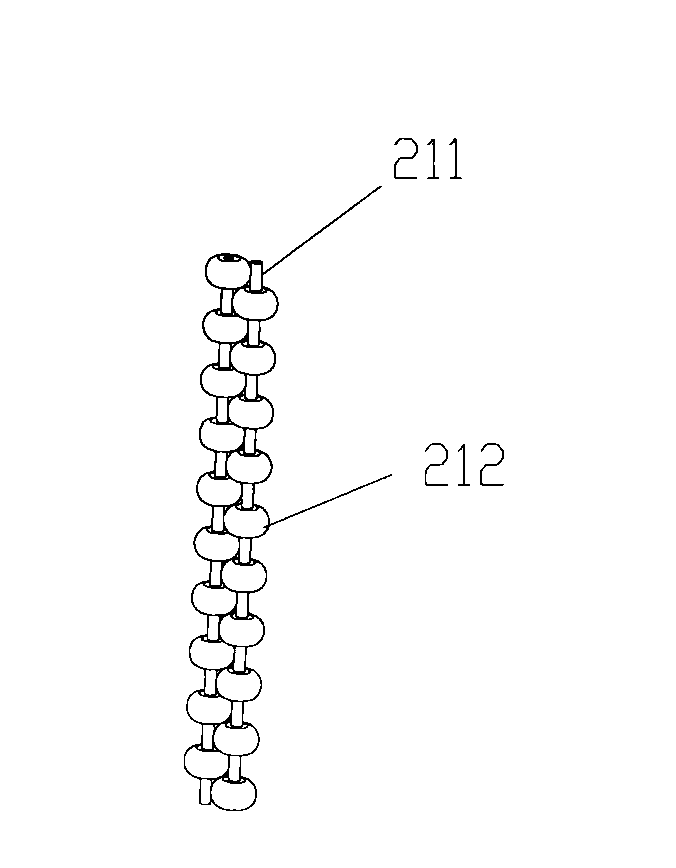

[0022] see Figure 1 to Figure 3 , the inner tub for the washing machine according to the embodiment of the present invention includes an inner tub bracket 1 and an inner tub 2 . The inner tub support is composed of a bracket top seat 11, a bracket base 12, and a bracket column 13. In order to increase the strength of the inner tub and ensure the safety and reliability of high-speed rotation, four bracket vertical plates 14 are added to the inner tub bracket to ensure the strength of the inner tub . The support columns 13 are circumferentially arranged at certain intervals, and the chain beads 21 are coaxially set on the support columns 13 , and the chain beads 21 are ring-shaped to form the inner barrel body 2 . Wherein the chain bead 21 includes two parts of a hollow tube 211 and a sphere 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com