Analytic method of acrylonitrile material

An analysis method and technology of acrylonitrile, which is applied in the field of analysis of acrylonitrile materials, can solve the problems of low content, qualitative and quantitative analysis, etc., and achieve high sensitivity detection and accurate quantification, good quantitative accuracy and repeatability, and good technology effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

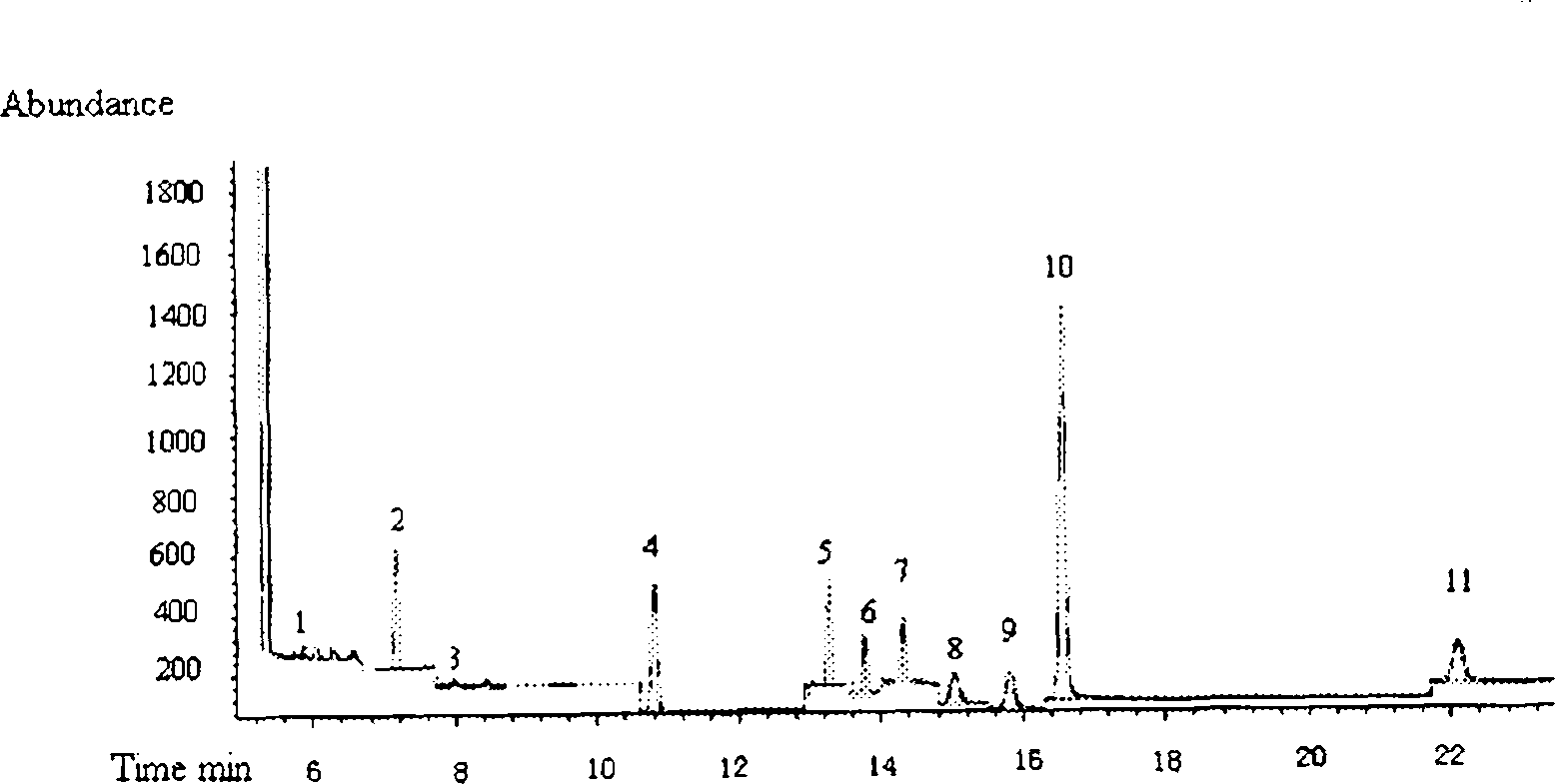

[0022] Adopt gas chromatography-mass spectrometry analysis method of the present invention, take toluene as internal standard substance, to containing acetaldehyde, acetone, acrolein, benzene, methacrylonitrile, methyl methacrylate, acetonitrile, oxazole, propionitrile, cis - Acrylonitrile standard samples of ten trace organic impurities were analyzed. The standard sample is injected from the split inlet of the gas chromatography, and the components are separated by the capillary column, and then enter the mass spectrometry system through the transfer line, and are detected by the quadrupole mass spectrometer detector and the selected ion detection mode, and the internal standard method is used for quantification. Typical analysis conditions are shown in Table 1. Standard 1 # Relative mass correction factor for determination of each impurity, standard 2 # analyzed as the sample to be tested. The selected ion detection diagram of the standard sample is shown in figure 1 , S...

Embodiment 2

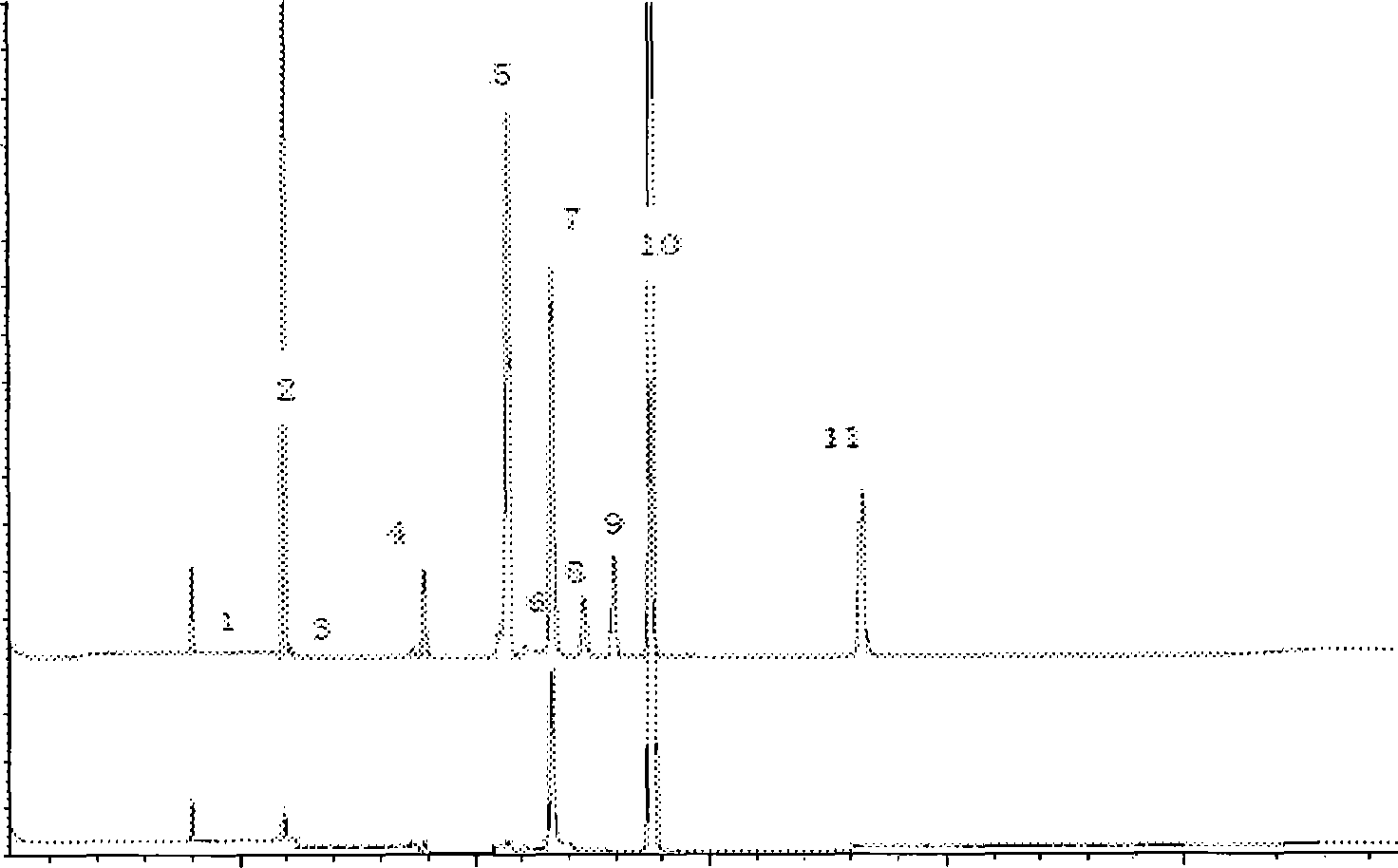

[0029] The gas chromatography-mass spectrometry analysis method of the present invention is used to analyze the actual samples before and after refining the acrylonitrile with toluene as an internal standard. The sample is injected by the split inlet of gas chromatography, and each component is separated by capillary chromatographic column, and then enters the mass spectrometry system through the transmission line, and is detected by the quadrupole mass spectrometer detector and the selected ion detection mode, and the internal standard method is used for quantification. Typical analysis conditions are shown in Table 1, and the selected ion detection diagrams of acrylonitrile samples before and after purification are shown in figure 2 , and the analysis results are shown in Table 3.

[0030] Table 3 Analytical results of the actual sample of acrylonitrile before and after refining mk / kg (w / w)

[0031] components

[0032] As can be seen from the measurement results ...

Embodiment 3

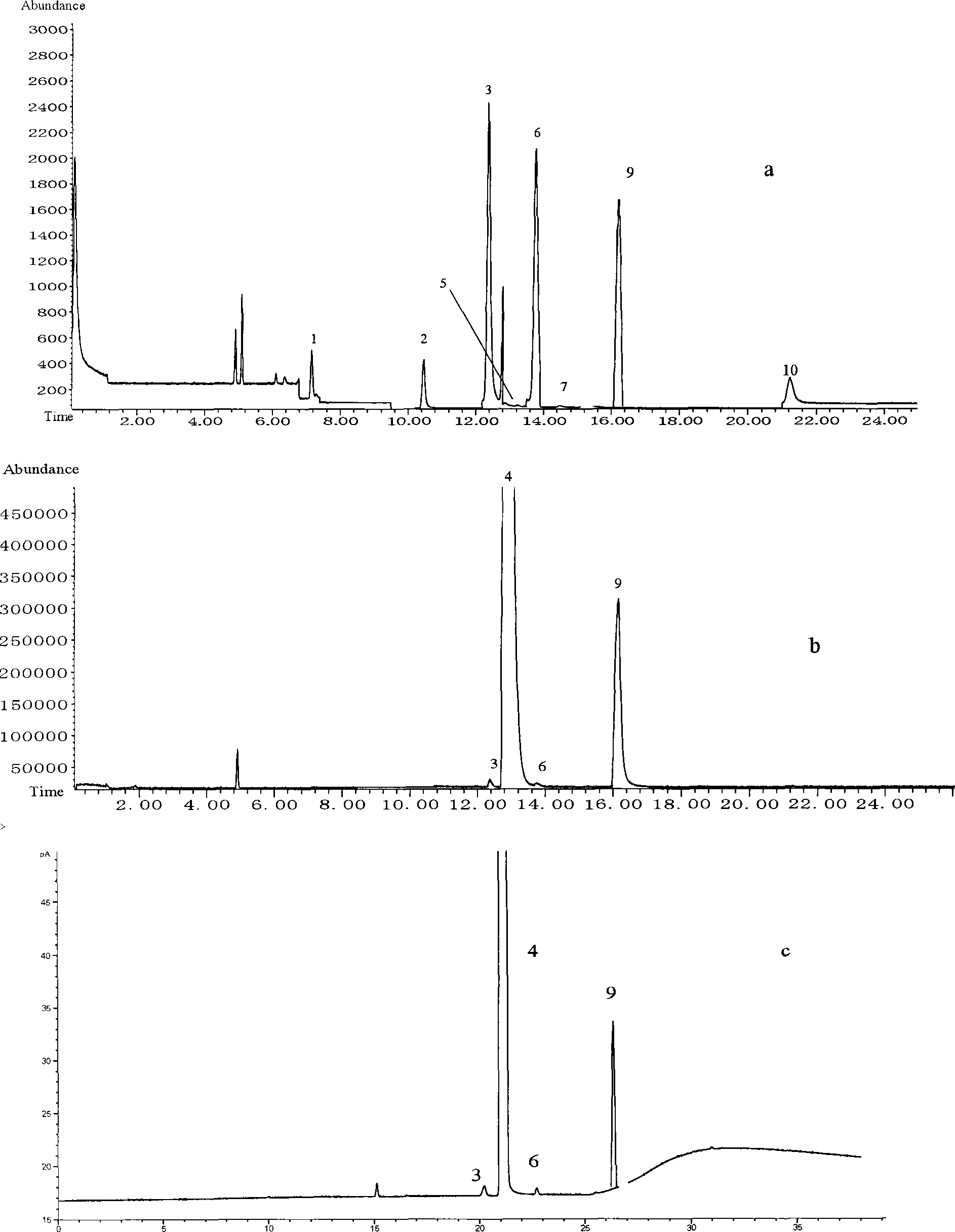

[0034]Using the gas chromatography-mass spectrometry analysis method of the present invention, an actual sample of high-purity acrylonitrile is analyzed with toluene as an internal standard. The sample is injected by the split inlet of gas chromatography, and each component is separated by capillary chromatographic column, and then enters the mass spectrometry system through the transmission line, and is detected by the quadrupole mass spectrometer detector and the selected ion detection mode, and the internal standard method is used for quantification. Typical analysis conditions are shown in Table 1. The comparison of this method with the gas chromatography-mass spectrometry / full scan (Scan) method and the standard method GB / T7717.12-2008 measurement results is shown in Table 4, and the chromatogram is shown in image 3 . The gas chromatography-mass spectrometry / full scan (Scan) method mass range is 15-200, and the rest of the analysis conditions are the same as in Table 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com