Industrial analysis instrument for parallel test

An industrial analyzer and Y-axis technology, applied in the field of industrial analyzers, can solve problems such as not being able to fully satisfy online analysis, reduce instrument test efficiency, and prolong test time, so as to shorten the total analysis time, test time, and positioning range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

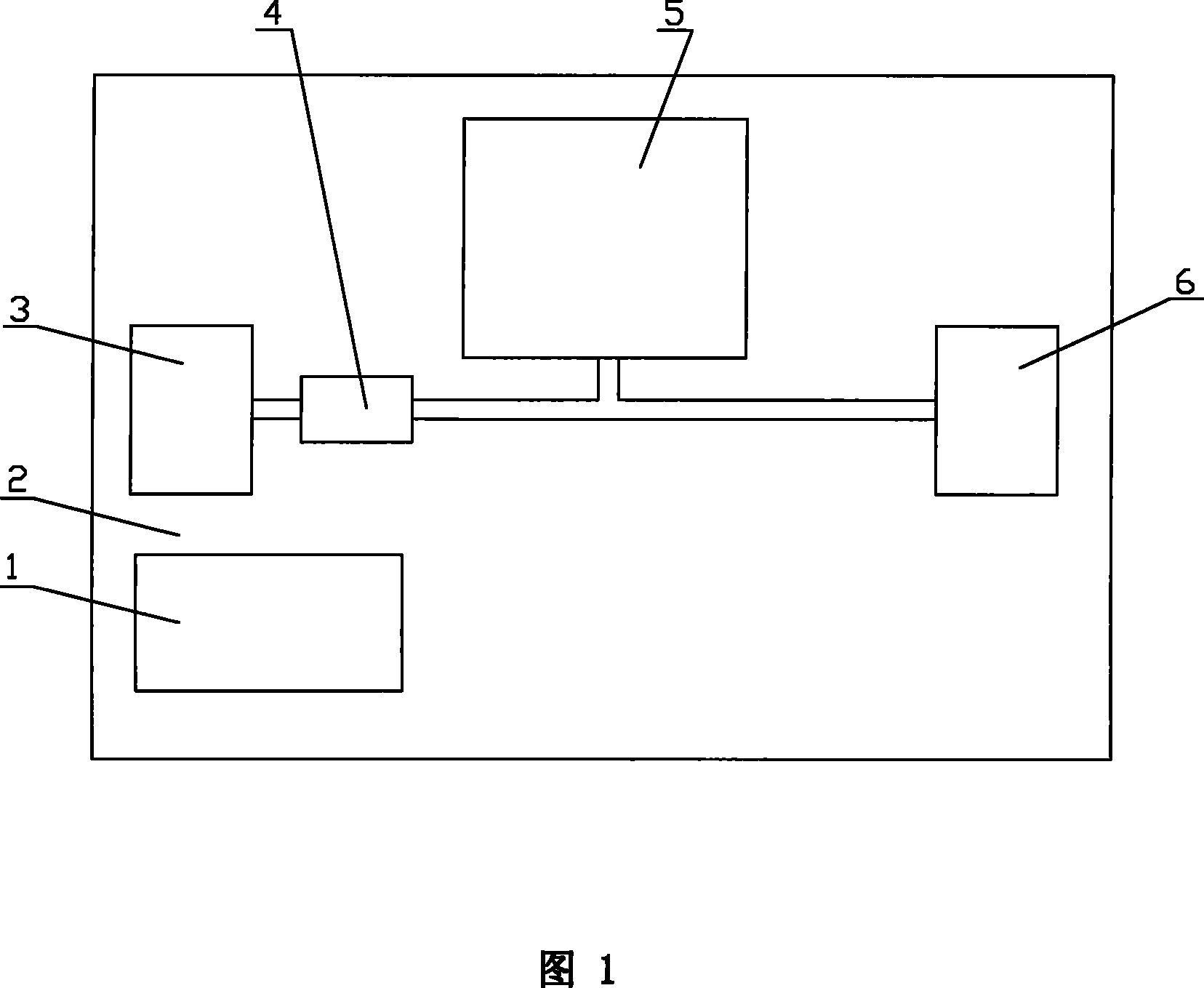

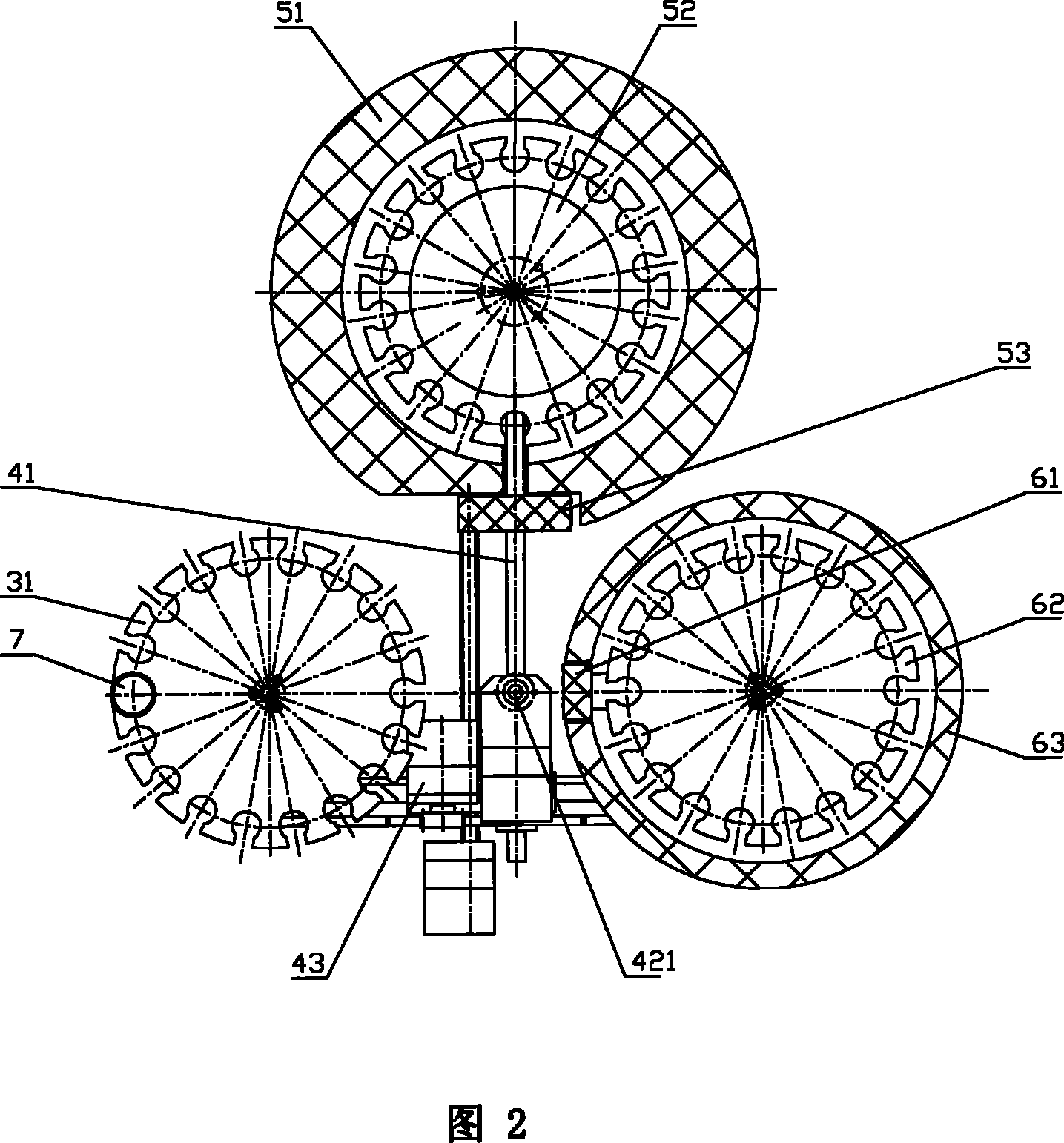

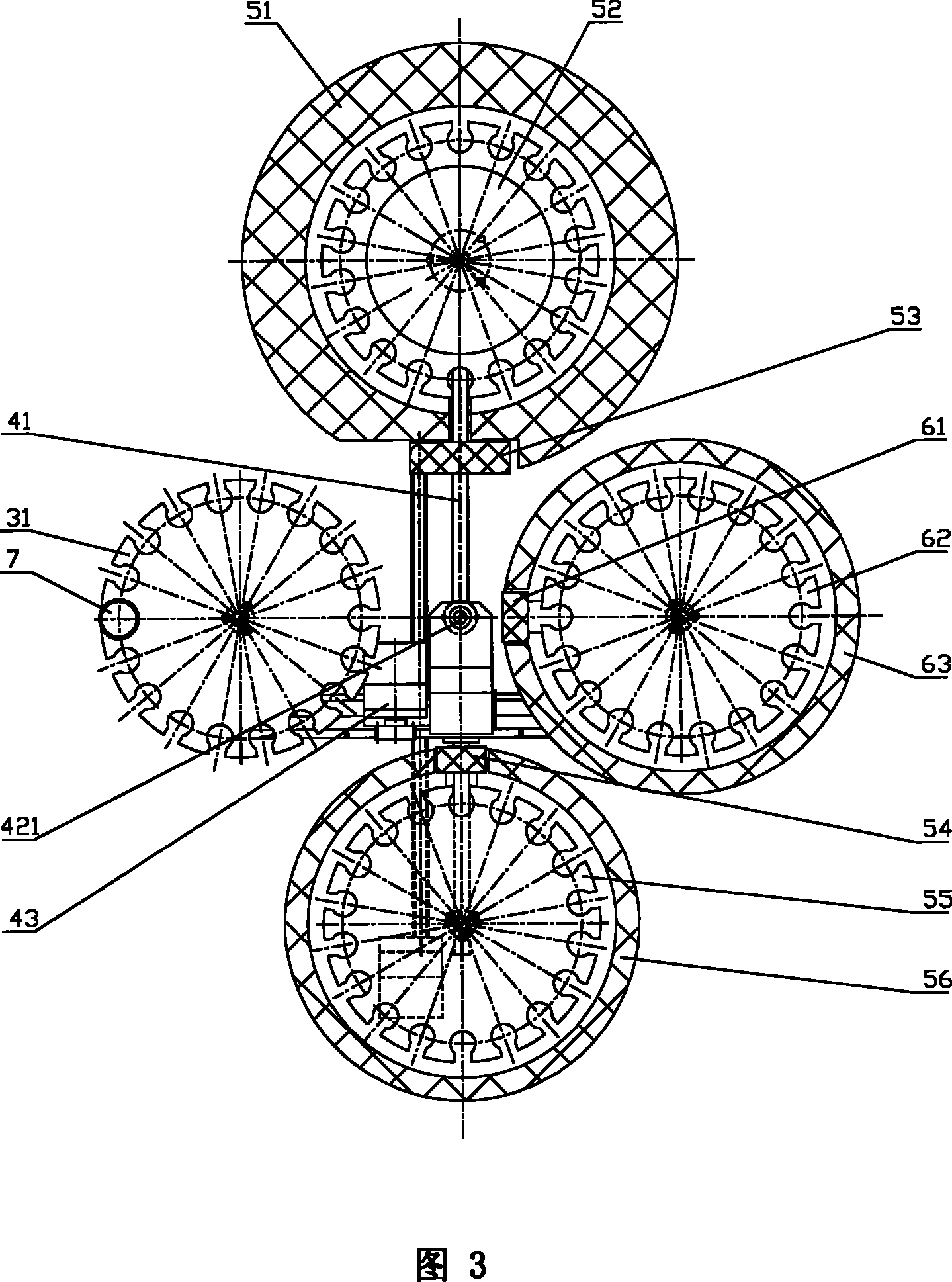

[0026]An industrial analyzer capable of parallel testing of the present invention comprises a control mechanism 1 fixed on a base plate 2, a sample feeding weighing mechanism 3, a sampling mechanism 4, an analysis furnace 5 and a heat preservation weighing mechanism 6, and a sampling mechanism 4 is located between the sample feeding and weighing mechanism 3, the analysis furnace 5 and the heat preservation weighing mechanism 6. Comprising one or more furnace bodies, the sampling mechanism 4 includes a Y-axis horizontal movement mechanism 41, an X-axis horizontal movement mechanism 43, and a manipulator lifting mechanism 42 fixed on the Y-axis horizontal movement mechanism 41 or the X-axis horizontal movement mechanism 43. The analysis furnace 5 can be one or more high-temperature furnace bodies. The high-temperature furnace body includes a high-temperature plate and a high-temperature furnace. The high-temperature furnace is connected to the sampling mechanism 4 through a high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com