A filter plate for the lower tube seat of the nuclear fuel assembly that is easy to process and its processing technology

A technology for nuclear fuel assemblies and filter plates, which is applied in the assembly of fuel elements, nuclear power generation, and greenhouse gas reduction, etc., can solve the problems of difficult processing and manufacturing and high manufacturing costs, and achieve low processing difficulty, sufficient structural strength, and good filtering effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

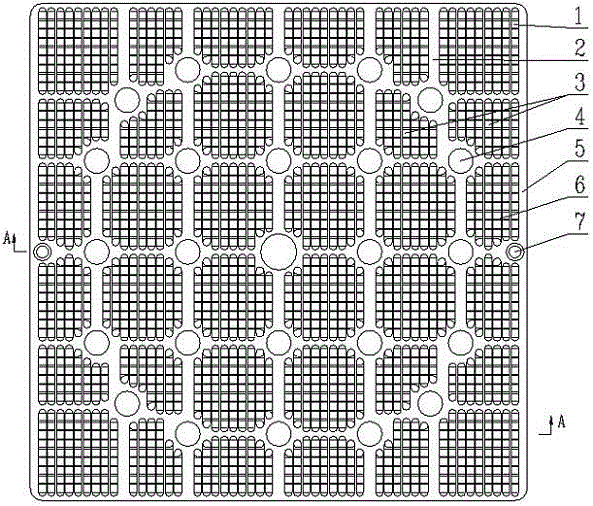

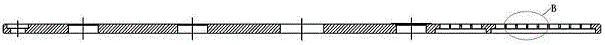

[0045] like figure 1 , 2 As shown in and 3, the present invention is mainly composed of a filter plate body 5, which is a whole plate, and the whole plate is also provided with a connecting hole 4 and a fixing pin correspondingly according to the opening position of the lower tube seat of the fuel assembly Holes 7; the upper and lower surfaces of the whole plate are provided with several elongated grooves 8, and the shape of the elongated grooves 8 can be as follows Figure 5 Rectangular as shown, can also be as Image 6 wavy as shown, or as Figure 7 zigzag as shown; Figure 4 As shown, the elongated grooves 8 respectively arranged on the upper and lower surfaces of the entire plate are in a space intersecting structure, thereby forming filter holes 1 .

[0046] In order to ensure the structural strength of the entire filter plate and the circulation area of the cooling liquid, such as figure 1 As shown, the present invention divides the filter plate body 5 into severa...

Embodiment 2

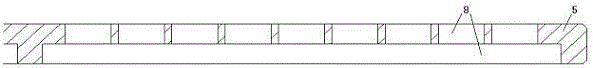

[0049] This embodiment differs from Embodiment 1 in that there are at least two filter plate bodies 5 Figure 8 The thin plates shown are stacked, and each thin plate is provided with a plurality of elongated holes 9, and the filter holes 1 are formed by at least two elongated holes 9 respectively arranged on different thin plates in a space cross structure, in order to To better form the filter hole 1, in this embodiment, two adjacent thin plates are rotated 90 degrees and then superimposed, and in order to prevent the direct bonding of the two thin plates to cause a decrease in the flow rate of the cooling liquid, it can be placed between the two thin plates A spacer is added to the connection hole 4 so that it does not fit directly.

[0050] The thin plate can be made of a material with better structural strength, and the elongated hole 9 formed by punching can preliminarily filter the foreign matter in the coolant, and play the effect of filtering for the first time. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com