A lower pipe seat of nuclear fuel assembly with a filter plate and its filter plate processing technology

A technology for nuclear fuel assemblies and fuel assemblies, which are applied in the assembly of fuel elements, nuclear power generation, and reduction of greenhouse gases, etc., can solve the problems of uneven flow distribution, low flow area share, and low flow at the four corners, and increase the flow area share. , Increase the share of circulation area and improve the effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

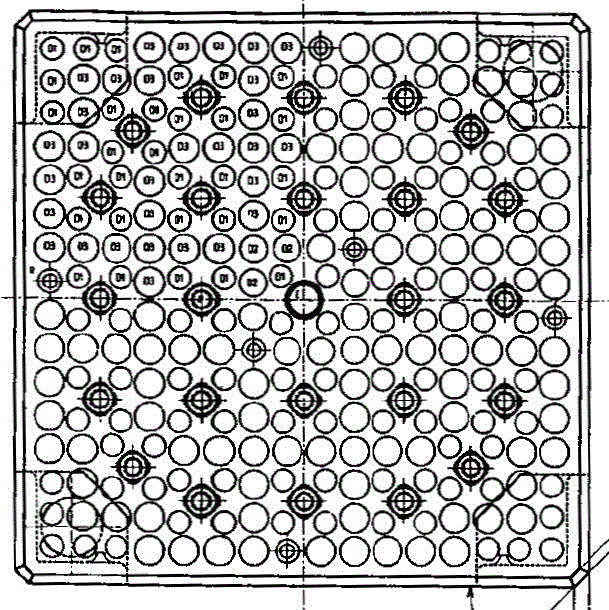

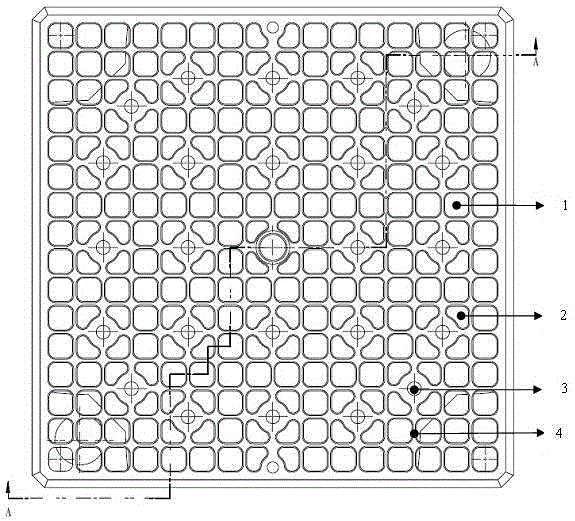

[0056] like figure 2 , 3 , 4, the present invention includes a square connecting plate 4 and four legs 5 at the lower part of the connecting plate 4, so as to form a bench-like structure as a whole. 3 It is used to install the fuel assembly guide tube, and the water flow hole is used to pass the coolant; in order to increase the flow area share, reduce the pressure drop, and improve the economy of the fuel assembly, the design of the water flow hole should be based on ensuring the structural strength. The larger the distribution area on the connecting plate 4, the better. In order to achieve this purpose, the water flow holes in the present invention adopt triangular water flow holes 2 and square water flow holes 1, wherein: the triangular water flow holes 2 are distributed around the connection hole 3, and are wound around the connection hole 3. The connecting holes 3 are arranged in a circle. Except for the parts where the connecting holes 3 and the triangular flow holes 2...

Embodiment 2

[0061] like figure 2 , 3 , 4, the difference between this embodiment and Embodiment 1 is only that grooves 6 are respectively opened on the four corners of the lower end face of the connecting plate 4, which not only reduces the thickness of the local connecting plate 4, but also reduces the Its material cost; and it is beneficial to increase the coolant flow at the four corners, because usually the four corners of the connecting plate 4 are areas with a low flow rate, and by opening grooves at the four corners, the flow at the four corners is improved, that is, to increase the flow rate. The overall flow distribution uniformity of the lower tube seat is improved, the lateral flow of the coolant when passing through the lower tube seat is avoided, the overall flow distribution uniformity of the lower tube seat is improved, and the risk of failure due to vibration and abrasion of the fuel rod is reduced. Other parts of this embodiment are the same as those of Embodiment 1, an...

Embodiment 3

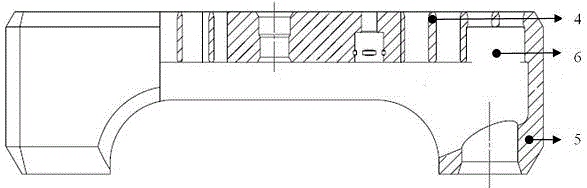

[0063] like figure 2 , 3 , 4, the difference between this embodiment and Embodiment 1 is that the inner surface of the leg 5 is also provided with an inclined surface 7 for guiding the coolant to flow through the lower cavity of the tube seat, and the inclined surface 7 constitutes a cooling In order to further reduce the pressure drop and improve the economy of the fuel assembly, the opening direction of the inclined surface 7 should satisfy the direction of guiding the cooling liquid toward the middle of the connecting plate 4, that is, the upper end of the inclined surface 7 should be located in the inner side of its lower end. Other parts of this embodiment are the same as those of Embodiment 1, and are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com