Molded conductor flexible metal armored optical cable composite power cable

A flexible metal and optical fiber composite technology, which is applied in the direction of power cables, power cables with shielding layers/conductive layers, cables, etc., can solve the problems of poor flame retardancy, difficult bending, and large outer diameter of cables, and achieve good environmental protection Flame retardant performance, dense cable core, convenient bending and laying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

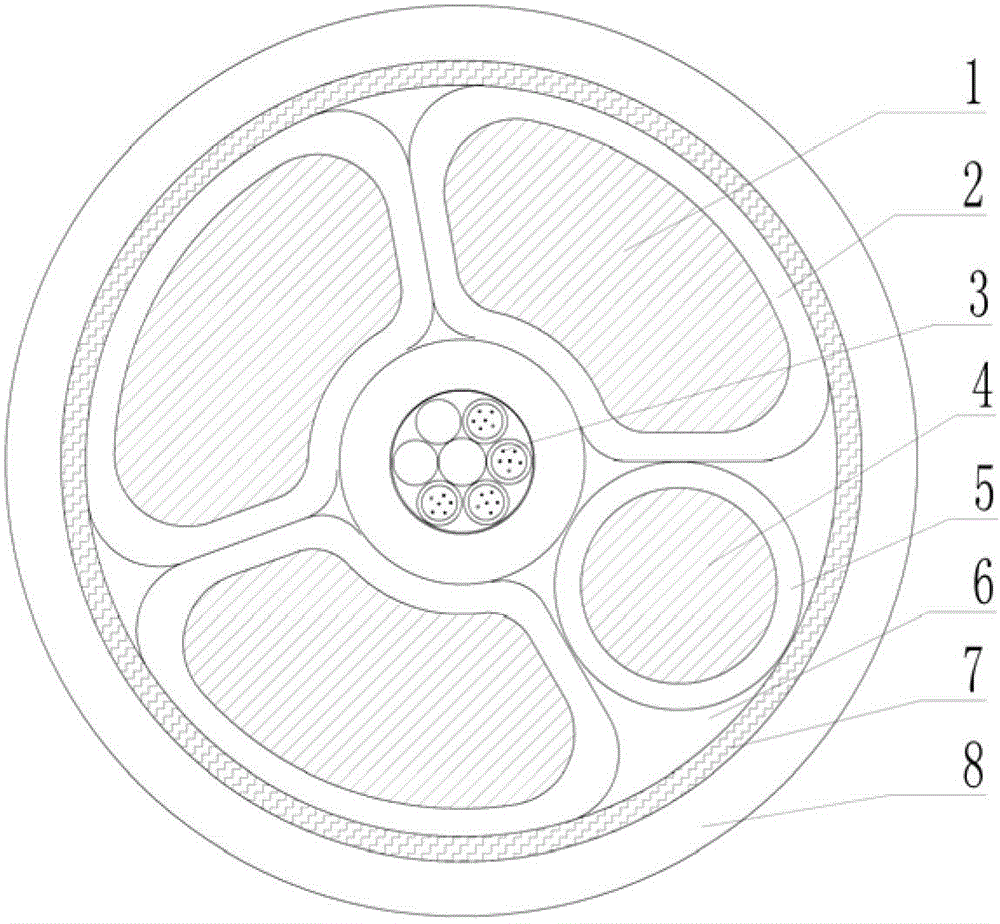

[0025] like figure 1 The shown shaped conductor flexible metal armored optical fiber composite power cable includes a cable core, a flexible metal armor layer 7 wound on the cable core, and an outer sheath 8 extruded on the flexible metal armor layer 7 .

[0026] The outer sheath 8 is made of extruded low-smoke halogen-free flame-retardant polyolefin sheath material, and its oxygen index should not be less than 36. The color of the outer sheath 8 is generally black, and can be adjusted to other colors according to customer requirements.

[0027] The flexible metal armor layer 7 is pre-rolled by aluminum alloy strips, and then wrapped on the cable core by covering, and the overlapping rate of covering is not less than 15%. The aluminum alloy strip of this example has a nominal thickness of 0.5mm.

[0028] The cable core is composed of 3 conductive cores, 1 grounding core, filler 6, and 1 optical cable 3 twisted together. The optical cable 3 is located in the center of the cab...

Embodiment 2

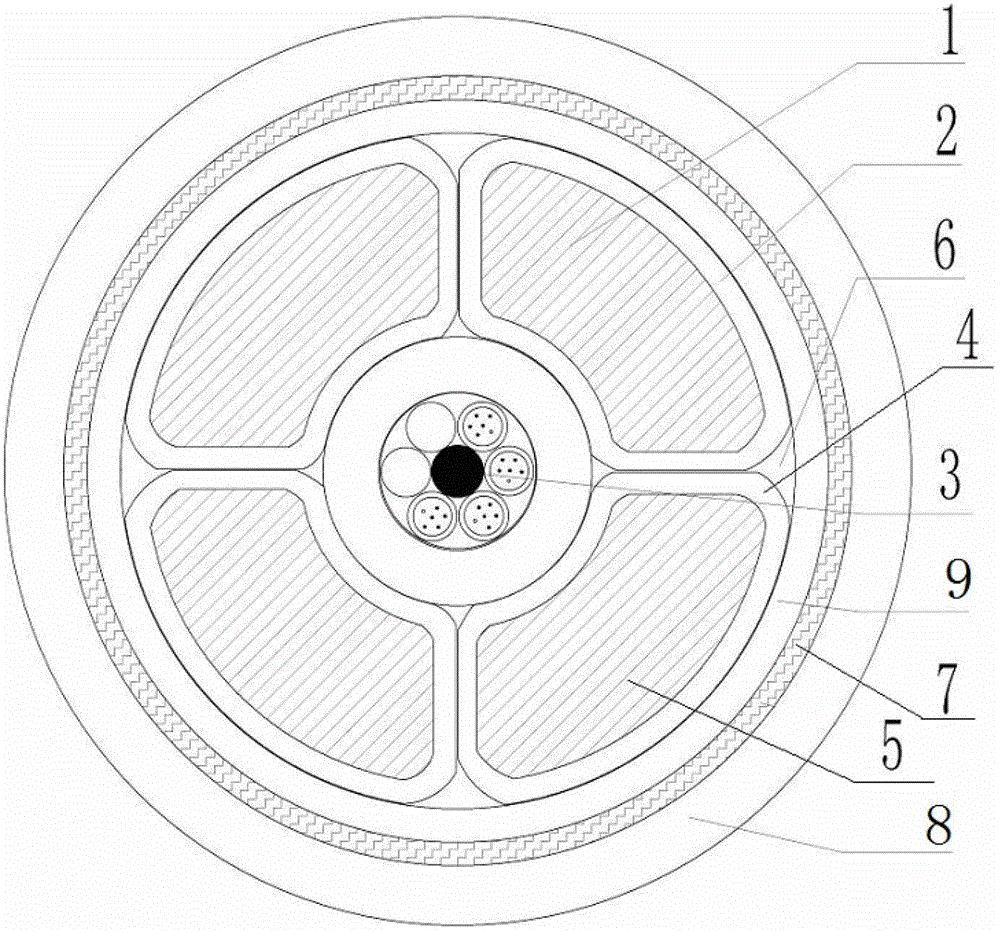

[0035] like figure 2 The shown shaped conductor flexible metal armored optical fiber composite power cable includes a cable core, an inner liner 9 coated outside the cable core, a flexible metal armor layer 7 wound on the inner liner 9 and extruded on a flexible Outer sheath 8 on metal armor layer 7.

[0036] The outer sheath 8 is made of extruded low-smoke halogen-free flame-retardant polyolefin sheath material, and its oxygen index should not be less than 36. The color of the outer sheath 8 is generally black, and can be adjusted to other colors according to customer requirements.

[0037] The flexible metal armor layer 7 is pre-rolled by aluminum alloy strips, and then wrapped on the cable core by covering, and the overlapping rate of covering is not less than 15%. The aluminum alloy strip of this example has a nominal thickness of 0.5 mm.

[0038] The inner liner 9 is made of extruded low-smoke, halogen-free, flame-retardant polyolefin sheath material, and its oxygen i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com