A density-controlled anti-bending cable

A technology of density control and bending, applied in the direction of bendable cables, insulated cables, cables, etc., can solve the problems of large outer diameter of power cables, difficulties in transportation and laying, and difficulty in finding defects in insulation, so as to achieve uniform overall deformation and improve Control the effect, avoid the effect of continuing to bend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

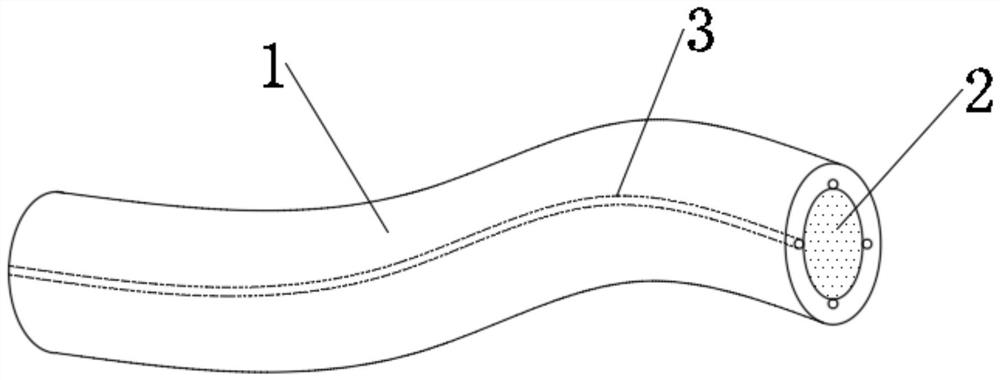

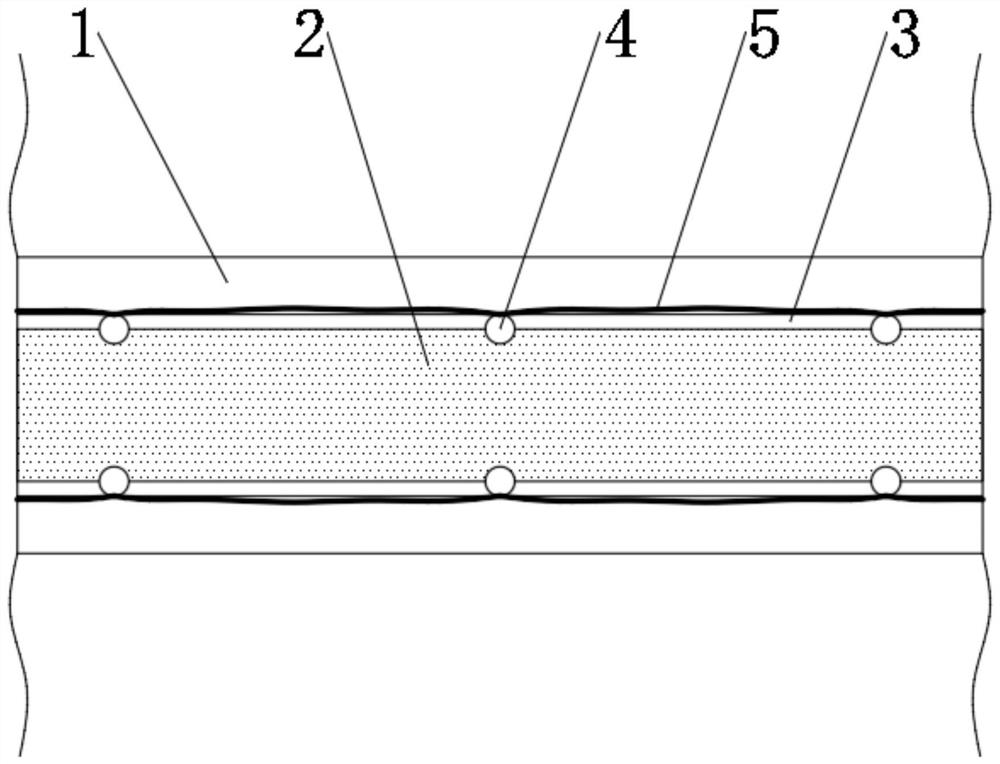

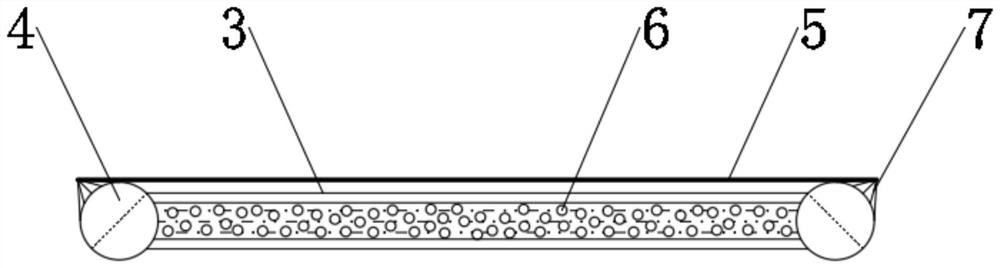

[0044] see Figure 1-2 , a density-controlled anti-bending cable, comprising an outer sheath 1, the inner end of the outer sheath 1 is inlaid and connected with a cable core 2, and a plurality of anti-bending chains are inlaid and connected between the outer sheath 1 and the cable core 2 , the anti-bending chain includes a plurality of hardened tubes 3 and density control balls 4, and the hardened tubes 3 and density control balls 4 are staggered and connected to each other, and a control cable 5 is connected between a pair of adjacent density control balls 4.

[0045] see Figure 3-4 , the density control sphere 4 includes a control hemisphere 41, a magnetic suction hemisphere 42 and an air tympanic membrane 43, the control hemisphere 41 and the magnetic suction hemisphere 42 are symmetrically connected, and the air tympanic membrane 43 is sleeved on the outer end of the connection between the control hemisphere 41 and the magnetic suction hemisphere 42 , and the air tympani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com