Frequency conversion cable with flexible metal sheath

A flexible metal, frequency conversion cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem that the shielding layer cannot simultaneously suppress electromagnetic wave emission and short-circuit current channels, so as to prevent excessive induction electric heating, prevent termites and fire resistance performance, the effect of reducing inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

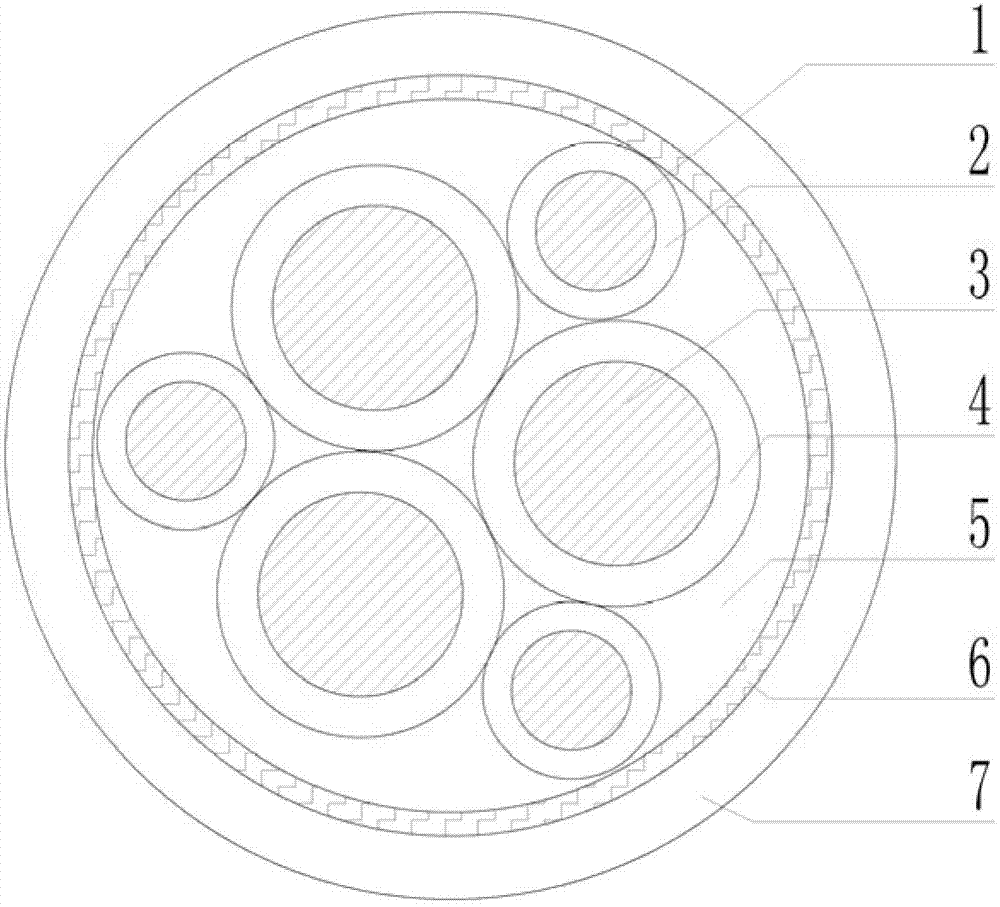

[0015] Such as figure 1 The frequency conversion cable with a flexible metal sheath, rated working voltage U 0 / U is 0.6 / 1kV. It includes an insulated wire core, a flexible metal sheath 6 wound on the insulated cable core, and a non-metallic outer sheath 7 wrapped outside the flexible metal sheath 6 .

[0016] The non-metallic outer sheath 7 is extruded from a temperature-resistant 90°C polyvinyl chloride sheathing material, with a nominal thickness of 1.8mm. The color of the non-metallic outer sheath 7 is generally black, and can be adjusted to other colors according to customer requirements.

[0017] The flexible metal sheath 6 is made of pre-rolled soft copper strip, which is wrapped on the insulating cable core by covering, and the overlapping rate of covering is not less than 20% when wrapping. The cross-section of the annealed copper strip is roughly Z-shaped, and its nominal thickness is 0.1mm.

[0018] The insulated cable core is composed of 3 main cores, 3 groundi...

Embodiment 2

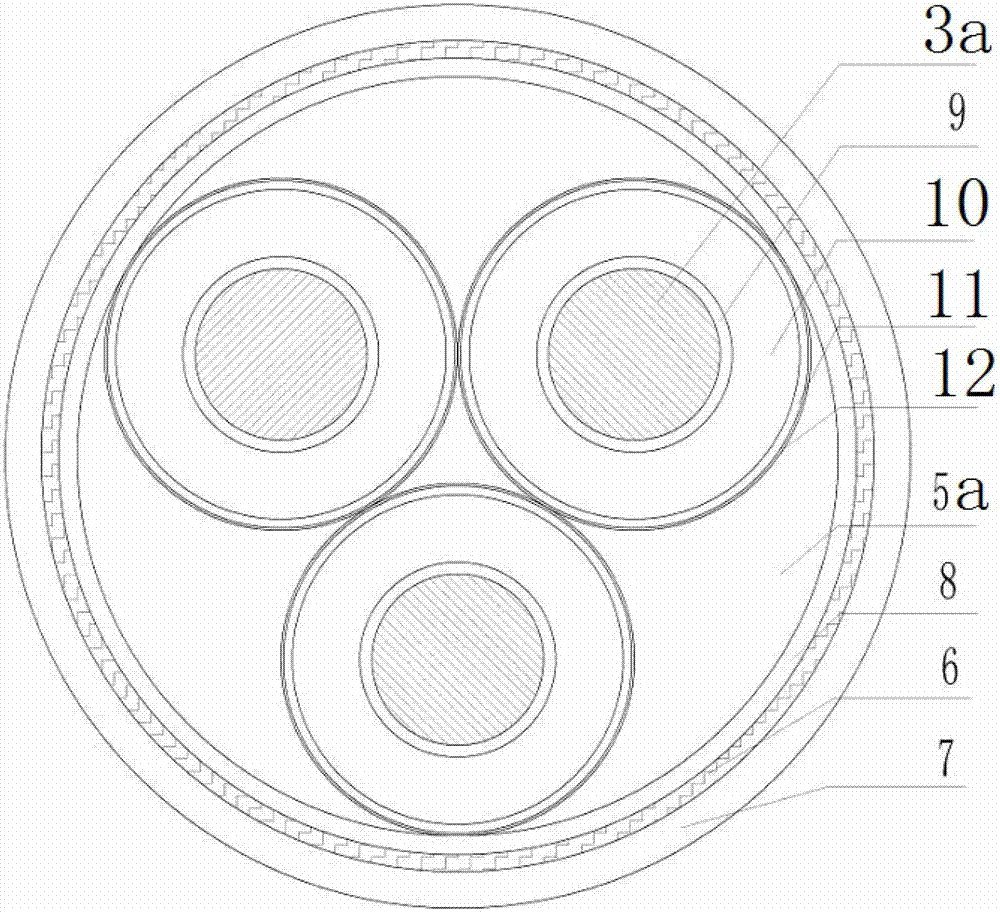

[0023] Such as figure 2 The frequency conversion cable with a flexible metal sheath, rated working voltage U 0 / U is 8.7 / 15kV. It includes an insulated wire core, a spacer 8 wrapped on the insulated wire core, a flexible metal sheath 6 wound on the spacer 8 , and a non-metallic outer sheath 7 wrapped outside the flexible metal sheath 6 .

[0024] The non-metallic outer sheath 7 is made of extruded polyvinyl chloride sheath material with a temperature resistance of 90°C, and the nominal thickness is 3.3mm. The color of the non-metallic outer sheath 7 is generally black, and can be adjusted to other colors according to customer requirements.

[0025] The flexible metal sheath 6 is made of pre-rolled soft copper strip, which is wrapped on the insulating cable core by covering, and the overlapping rate of covering is not less than 20% when wrapping. The cross-section of the annealed copper strip is roughly S-shaped, and its nominal thickness is 0.25mm.

[0026] The isolation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com