Cable bridge rack side board made of plastic and metal gauze and its manufacture method

A technology of wire mesh and cable bridge, which is applied in the direction of pipe supports, coatings, mechanical equipment, etc., can solve the problems of cumbersome manufacturing process, high manufacturing cost, and poor strength, and achieve improved safety performance, low cost, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

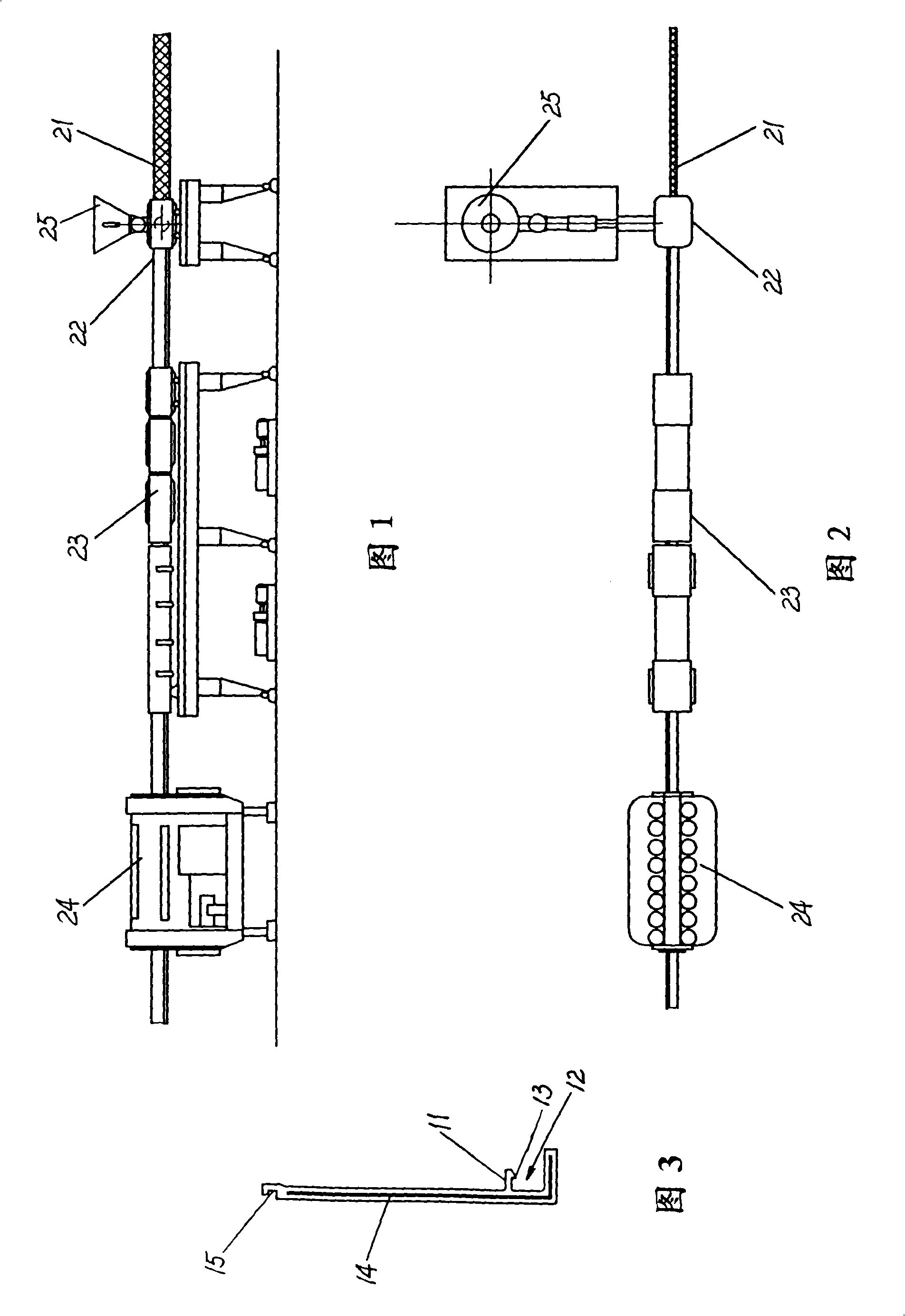

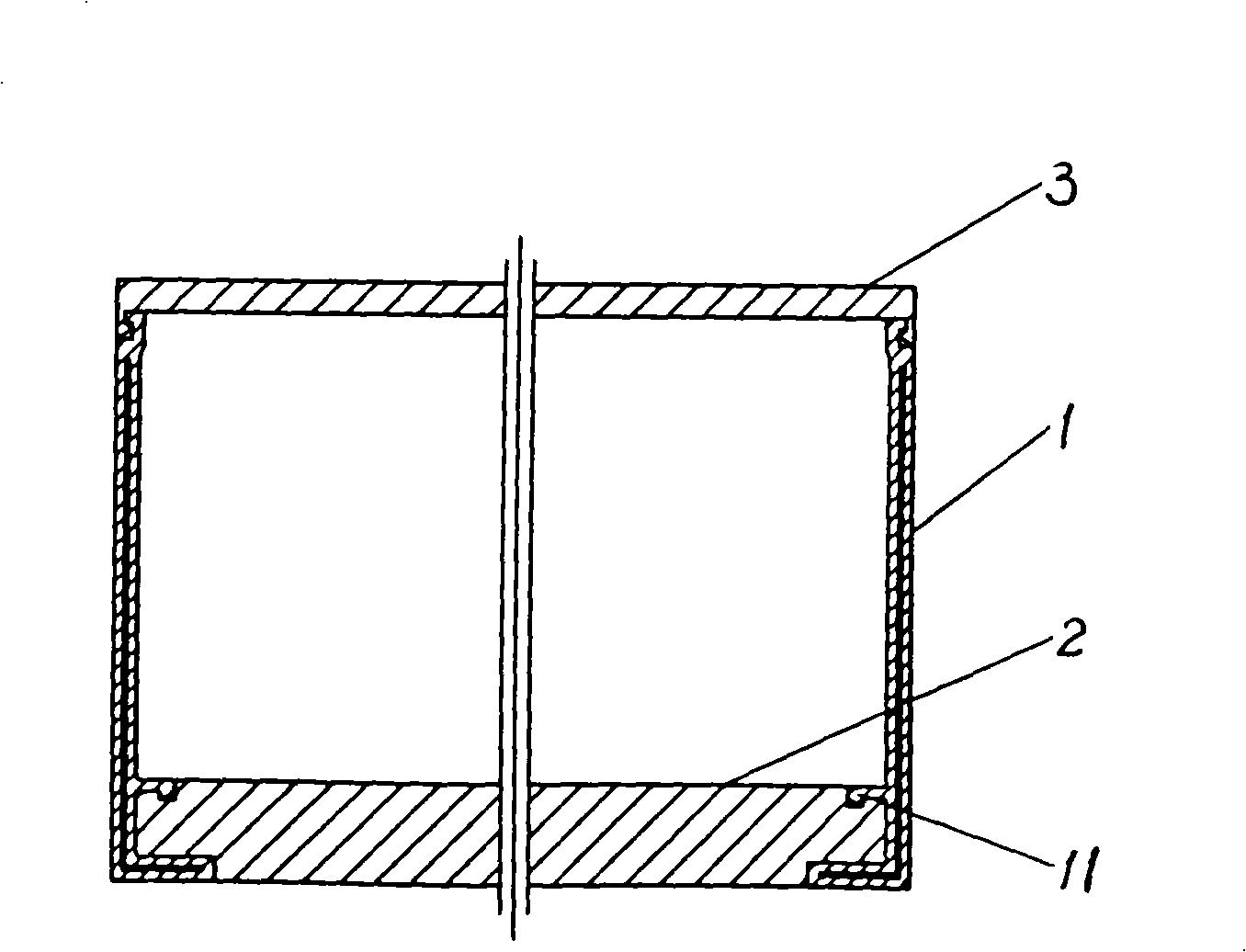

[0028] See Figure 1 to Figure 4 , the present invention is a side plate of a cable bridge made of plastic and wire mesh composite material and a method for making the side plate, and the side plate is connected and installed on the cable bridge. The cable tray is composed of a side plate 1, a bottom plate 2 and a cover plate 3.

[0029] As shown in FIG. 1 , the side plate 1 is L-shaped, and a clip 11 is provided at the bottom of the side plate to form a card socket 12 for installing the bottom plate 2 . The protruding end of the clip of the cassette socket 12 is provided with a drooping ratchet 13, and the ratchet can hook into the groove of the bottom plate. The bottom plate can adopt the bayonet insertion method. When inserting, the clips of the socket are deformed by force. Once inserted in place, the clips will spring back to their original shape.

[0030] A metal grid frame 14 is arranged inside the plastic surface of the side plate 1, which acts as a reinforcing rib. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com