Longitudinal beam of combined wood-plastic pallet

A combined, wood-plastic technology, used in rigid containers, containers, packaging, etc., can solve the problems of not being able to completely replace wooden pallets, large structural shapes, thick walls, etc., and achieve high shear strength and product quality. The effect of high density and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

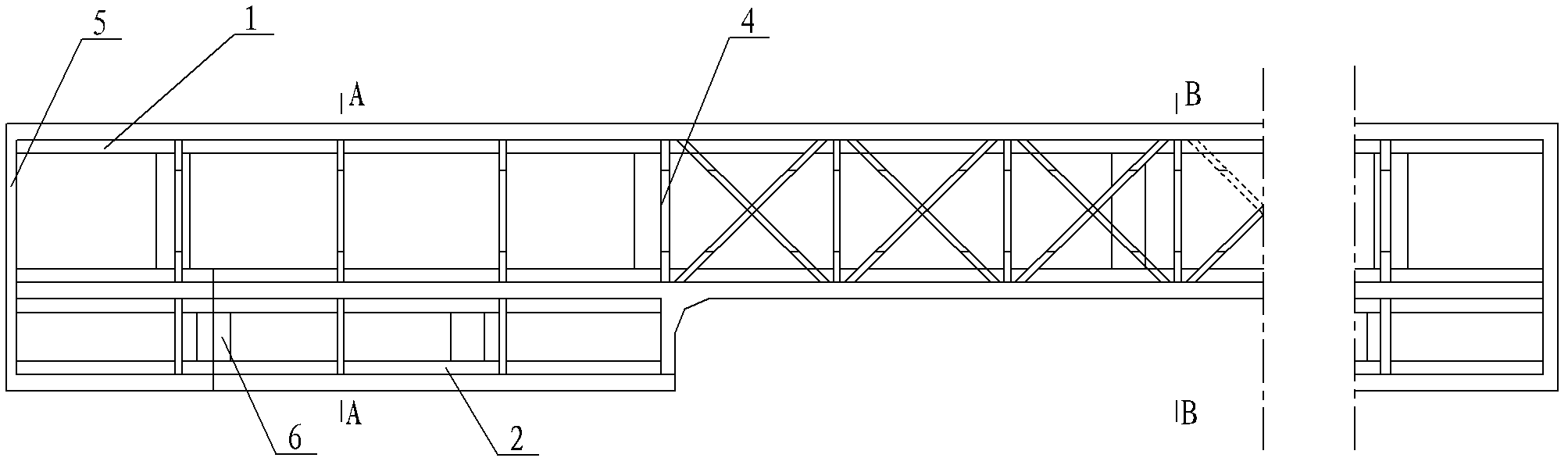

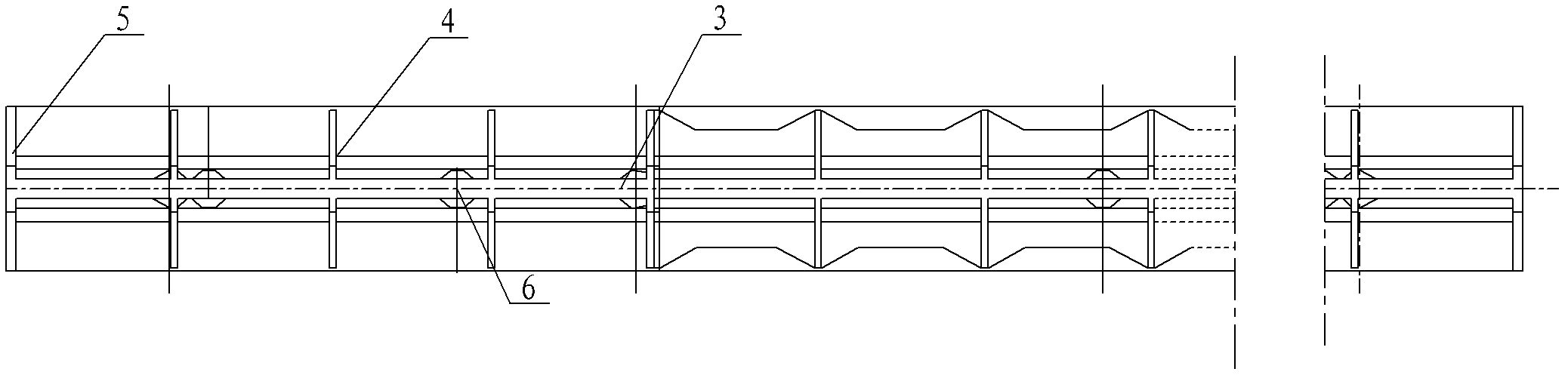

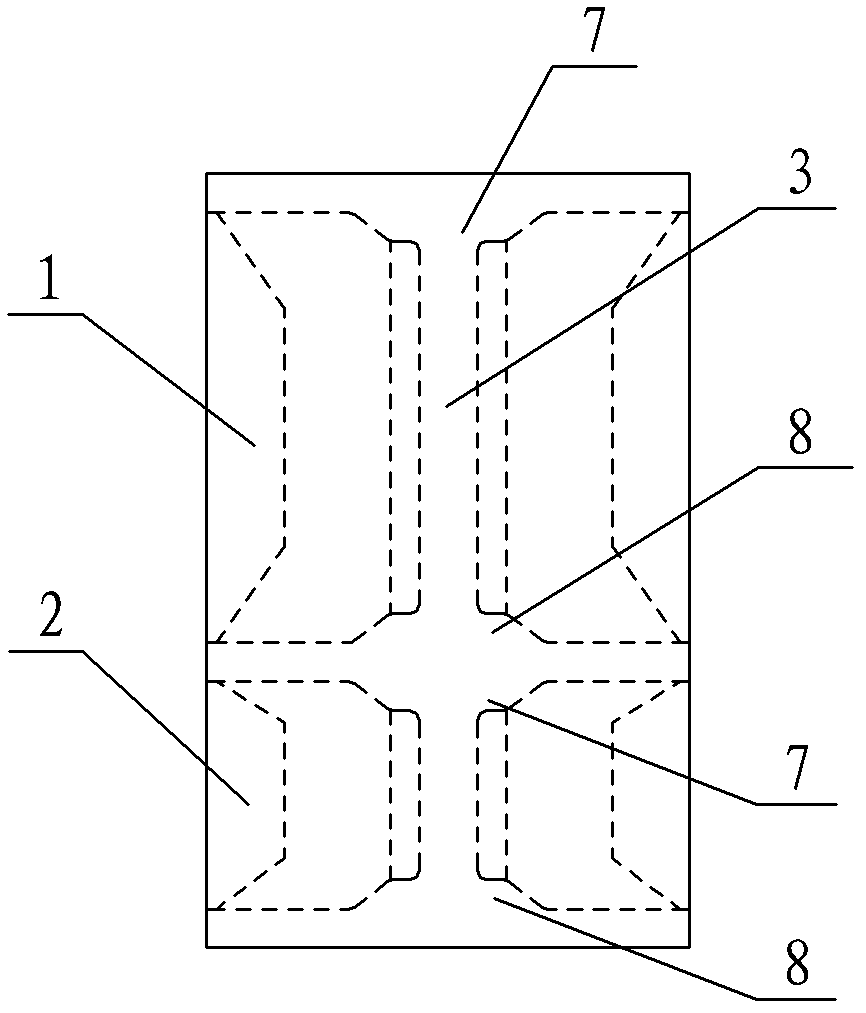

[0027] A combined wood-plastic pallet stringer provided in this embodiment has a structure such as Figure 1 to Figure 11 As shown, the upper beam 1 and the lower beam 2 are included, and the lower beam 2 of the cylinder is arranged at the bottom of the upper beam 1 of the cylinder at intervals, and arched forklift holes are formed between the lower beams 2; the upper beam and the lower beam of the cylinder are formed by the upper The bottom plate 7, the lower bottom plate 8, the middle main wall 3 and the vertical rib 4 arranged between the upper and lower bottom plates form a full-length structure, and the thickness of the middle main wall is 6 mm; the cylindrical vertical rib 4 is along the length direction of the cylindrical full-length structure set at intervals, and perpendicular to the axis of the overall length direction of the cylindrical overall length structure, the central main wall 3 of the cylindrical body is arranged along the overall length direction of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com