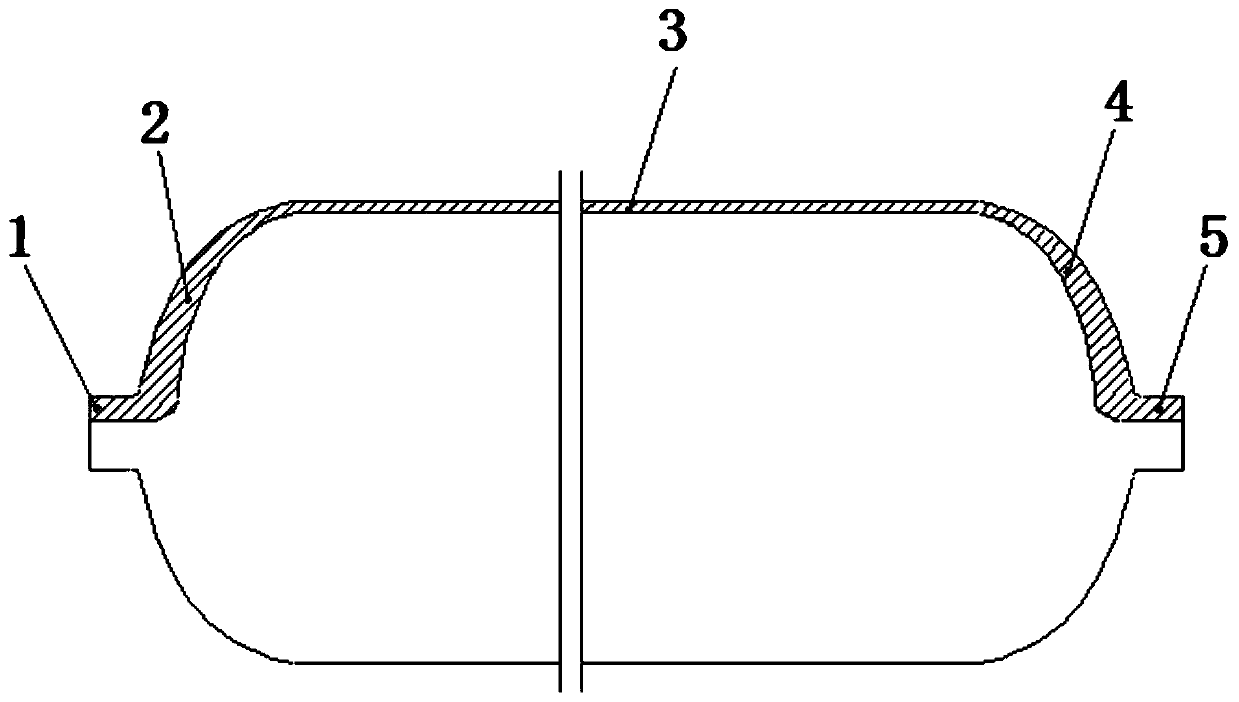

Manufacturing method of double-head high-pressure gas cylinder liner

A technology for high-pressure gas cylinders and manufacturing methods, applied in the field of high-pressure containers, capable of solving problems such as heavy weight, poor reliability, and small volume of high-pressure gas cylinders, and achieving the effects of low pollution, increased overall diameter and size, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

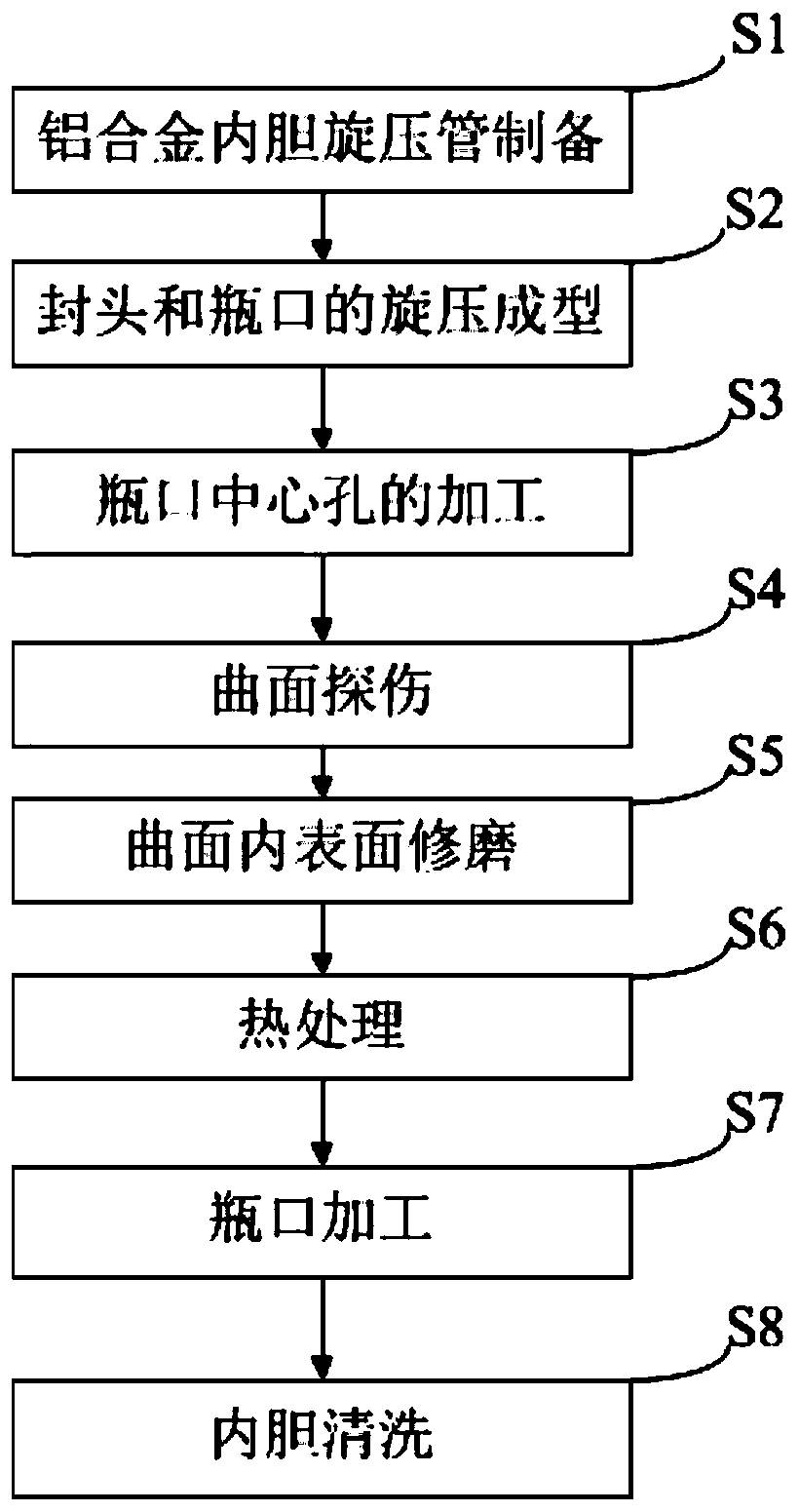

[0106] Prepare a double-headed high-pressure gas cylinder liner with a diameter of Φ420mm, a length of 2.5m, and a wall thickness of 4mm. The rated pressure of the high-pressure gas cylinder is required to be 25Mpa, specifically including the following steps:

[0107] S1, the preparation of aluminum alloy liner spinning tube, this step specifically includes the following steps:

[0108] S11, the spinning forming of the straight section 3 of the aluminum alloy liner spinning tube, using the three-wheel staggered forward spinning method to carry out two-pass spinning on the seamless tube blank with a length of 1m, and the three-wheel staggered forward spin The misalignment in the pressing method is set to 6mm;

[0109] The spinning part A is obtained, and the spinning part A is a straight tube of equal thickness or a straight tube section 3 with an outer circumferential end frame at both ends; the size of the spinning part A is: the total length is 3000mm, and the thickness of t...

Embodiment 2

[0142] Prepare a double-head high-pressure gas cylinder liner with a diameter of 618mm, a length of 4.5m, and a wall thickness of 6mm. The rated pressure of the high-pressure gas cylinder is required to be 25Mpa, specifically including the following steps:

[0143] S1, the preparation of aluminum alloy liner spinning tube, this step specifically includes the following steps:

[0144] S11, Spinning forming of the straight section 3 of the aluminum alloy liner spinning tube, the seamless tube blank with a length of 1.5m is 3 times spinning by the three-wheel staggered reverse spinning method, and the three-wheel staggered reverse spin The misalignment in the spinning method is set to 6mm;

[0145] The spinning part A is obtained, and the spinning part A is a straight tube of equal thickness or a straight tube section 3 with an outer circumferential end frame at both ends; the size of the spinning part A is: the total length is 4700mm, and the thickness of the straight tube secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com