High-voltage connection cable for electric vehicle interior with ultra-flexible aluminum conductor and manufacturing method

A technology for electric vehicles and connecting cables, applied in the direction of insulating conductors/cables, bendable cables, cable/conductor manufacturing, etc., can solve the problem that the degree of softness cannot meet the expected requirements, the labor intensity of construction personnel is high, and the manufacturing cost of flexible cables Large and other problems, to achieve the effect of light weight, low cost, and low transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

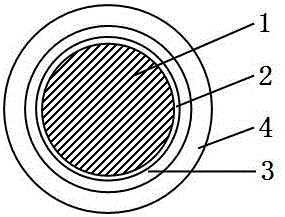

[0022] please see figure 1 , a high-voltage connection cable for electric vehicles with super soft aluminum conductors, including a conductor 1, a tape 2 covering the conductor 1, an insulating layer 3 covering the tape 2, and an extrusion coating outside the insulating layer 3 The sheath layer 4 is characterized in that the conductor 1 is twisted from the annealed fifth type annealed aluminum wire with a diameter of 0.10-0.45mm, and the cross-sectional area of the conductor is 1.5mm 2 ~120mm 2 , the material combination of the insulating layer 3 and the sheath layer 4 is one of the following three types: (1) The insulating layer 3 is 125°C environmentally friendly flame-retardant thermoplastic elastomer TPE, and the sheath layer 4 is 125°C environmentally friendly flame-retardant thermoplastic Elastomer TPE; (2) Insulation layer 3 is 125°C environment-friendly flame-retardant radiation cross-linked polyolefin, and sheath layer 4 is 125°C environment-friendly flame-retardan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com