High-voltage cable for internal connection of electric vehicle and manufacturing method thereof

An internal connection, electric vehicle technology, applied in the direction of power cable, cable/conductor manufacturing, power cable with shielding layer/conducting layer, etc. problems, to achieve the effect of material cost and transportation cost saving, excellent bending and torsion resistance, and excellent bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

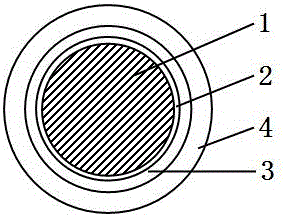

[0032] please see figure 1 , a high-voltage cable for internal connection of an electric vehicle, comprising a conductor 1, a tape 2 covering the conductor 1, an insulating layer 3 covering the tape 2, and a sheath layer covering the insulating layer 3 by extrusion 4. It is characterized in that the conductor 1 is composed of a plurality of annealed annealed annealed annealed aluminum wires with a diameter of 0.05-0.60 mm or the conductor 1 is composed of a plurality of galvanized wires with a diameter of 0.05-0.60 mm. Composed of aluminum wire or the conductor 1 is composed of a plurality of tinned aluminum wires with a diameter of 0.05-0.60mm, and the cross-sectional area of the conductor is 1.5mm 2 ~120mm 2 , the material of the insulating layer 3 is 125°C environment-friendly flame-retardant radiation cross-linked polyolefin, the material of the sheath layer 4 is 125°C environment-friendly flame-retardant thermoplastic elastomer TPU; the conductor is composed of multipl...

Embodiment 2

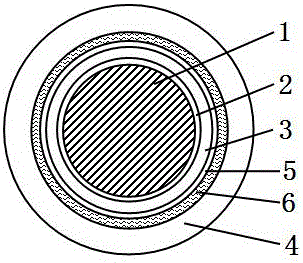

[0039] please see figure 2 , a high-voltage cable for internal connection of an electric vehicle, comprising a conductor 1, a tape 2 covering the conductor 1, an insulating layer 3 covering the tape 2, and a single-sided aluminum foil layer 5 covering the insulating layer 3 , the shielding layer 6 coated on the outside of the single-sided aluminum foil layer 5, the sheath layer 4 coated on the outside of the shielding layer 6 by extrusion molding, characterized in that the conductor 1 is made of a plurality of annealed conductors with a diameter of 0.05 to 0.60 mm of the fifth type soft aluminum wire or the conductor 1 is composed of a plurality of galvanized aluminum wires with a diameter of 0.05 to 0.60 mm or the conductor 1 is composed of a plurality of tinned aluminum wires with a diameter of 0.05 to 0.60 mm Aluminum wire, the cross-sectional area of the conductor is 1.5mm 2 ~120mm 2 The material of the insulating layer 3 is 125°C environment-friendly flame-retardant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com