Automatic tea making machine

A tea making machine and automatic technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of low degree of automation and time-consuming, and achieve the effect of fast tea production, avoiding thousands of boiling water, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

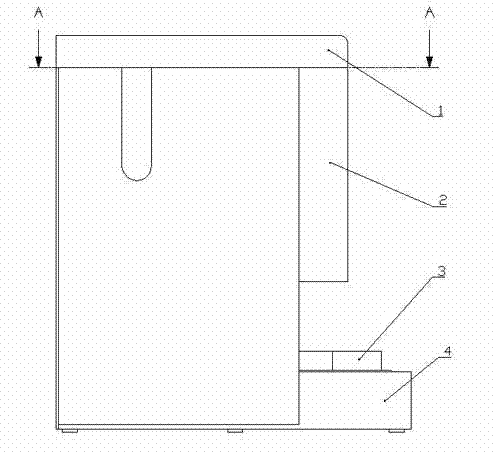

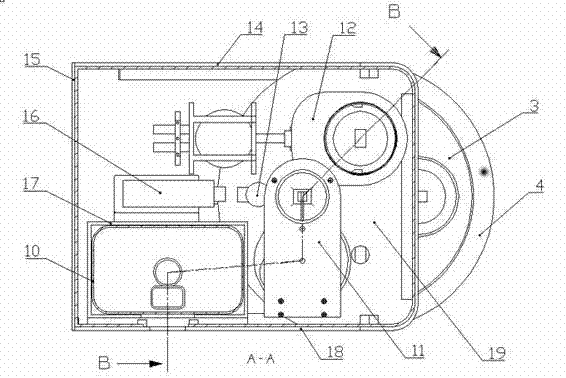

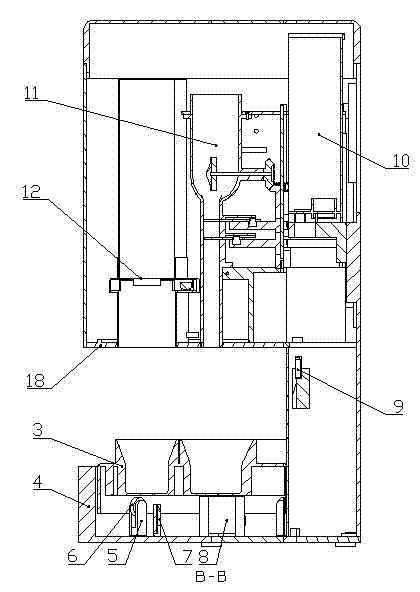

[0042] Such as Figure 1-Figure 5 As shown, an automatic tea making machine has a main body of the tea making machine, and the main body of the tea making machine includes a top cover 1, a bottom plate 4, a front cover 2, a right side plate 14, a left side plate 18 with a viewing window and a rear plate 15, The main body of the tea maker is equipped with a cup taking device 12 for holding cups and removing the cups one by one, and a tea feeding device 11 for holding tea leaves and injecting tea leaves quantitatively downwards. A multi-station turntable 3 with holes and automatic rotation, the multi-station turntable includes a station board 20, a plurality of station holes 21 are evenly arranged on the station board 20 and a supporting station board is installed at the bottom of the station board 20 20 bearings 6, and the bottom of the station plate 20 is provided with a photoelectric sensor 7; the tea maker also includes a processor, and the cup taking device 12, the tea ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com