Combined chamfering blade with blade pieces

A split-type, chamfering knife technology, applied in the direction of gear tooth manufacturing equipment, gear teeth, gear tooth manufacturing tools, etc., can solve the problems of narrow application range and single function, so as to improve product quality, improve efficiency, and reduce cutting tools The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further illustrate by the following examples.

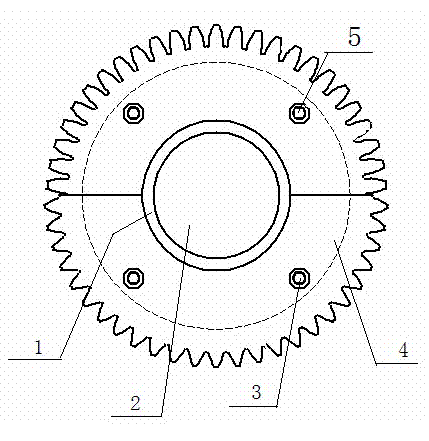

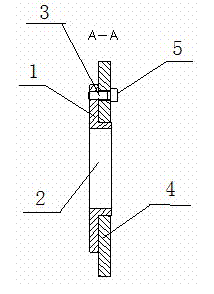

[0015] Cutter body 1 center has axle hole 2, and cutter blade 4 is coaxially installed on the cutter body 1, and cutter blade 4 is a group of 2-6 only to form a complete circular blade, and cutter blade 4 is semicircle or sector-shaped.

[0016] A screw hole 3 is provided along the periphery of the central axis hole 2 of the cutter body 1 .

[0017] There is a pillow block around the shaft hole 2 on the cutter body 1, and a screw hole 3 is opened on the pillow block.

[0018] There are cutter teeth on the outer edge of the knife flap 4, and screw holes 3 are opened on the inner edge periphery.

[0019] The present invention integrates a plurality of blades 4 with different tooth edges in the cutter body 1, and these blades 4 are combined into a complete blade to realize multifunctional chamfering on the same chamfering knife, and each blade 4 realizes its own The function of corresponding to a certain function requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com