Water-absorbing anti-spattering drainage channel

A drainage tank and drainage pipe technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of direct flow of cooling water, affecting health, affecting the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

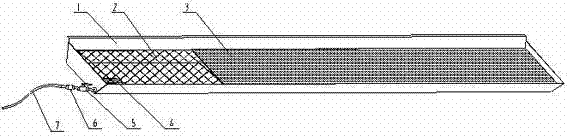

[0007] Referring to the accompanying drawings, the tank body 1 is made of stainless steel or other corrosion-resistant materials, and the water-proof net 2 is a mesh object made of stainless steel or other anti-corrosion materials. The water-proof net 2 is fixed in the groove of the tank body 1, and a Layer absorbent sponge3. A miniature submersible pump 4 is installed at the end of the tank body 1, and a drain valve 5, a quick-change joint 6 and a drain pipe 7 are externally connected. The cooling water ejected during the rail car welding operation or the water falling from a high place is quickly absorbed by the water-absorbing sponge 3 to avoid splashing. The water-insulating net 2 keeps the water storage space in the height direction in the tank and supports the absorbent sponge 3 to drain the absorbed water into the tank body 1 . Open the drain valve 5 and connect the quick-change joint 6 and the drain pipe 7, start the miniature submersible pump 4 and discharge the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com