Method for manufacturing window lens

A production method and technology for window lenses, which can be applied in installation, optics, instruments, etc., can solve the problems of insufficient bonding strength, easy separation of window lenses and plastic parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

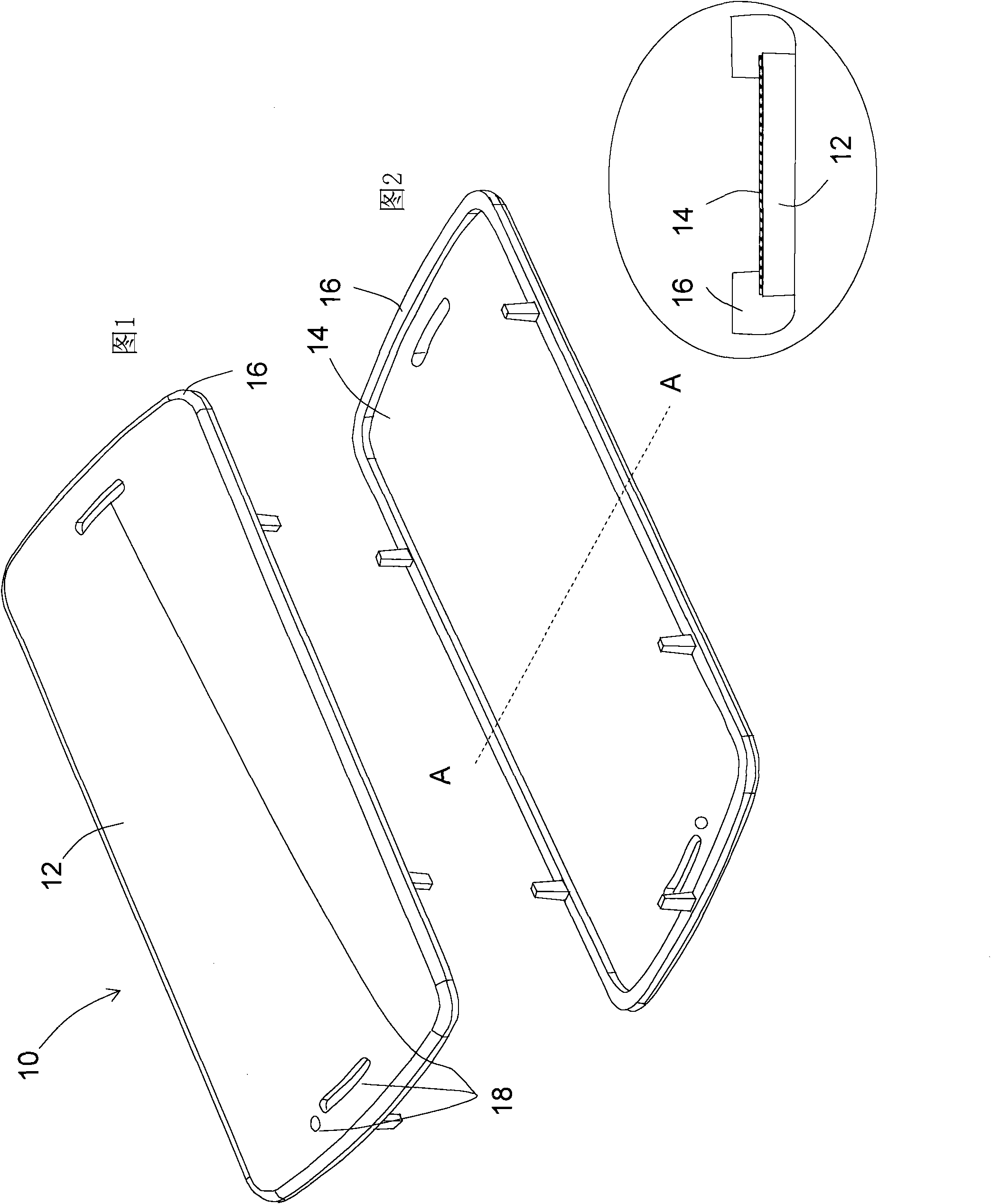

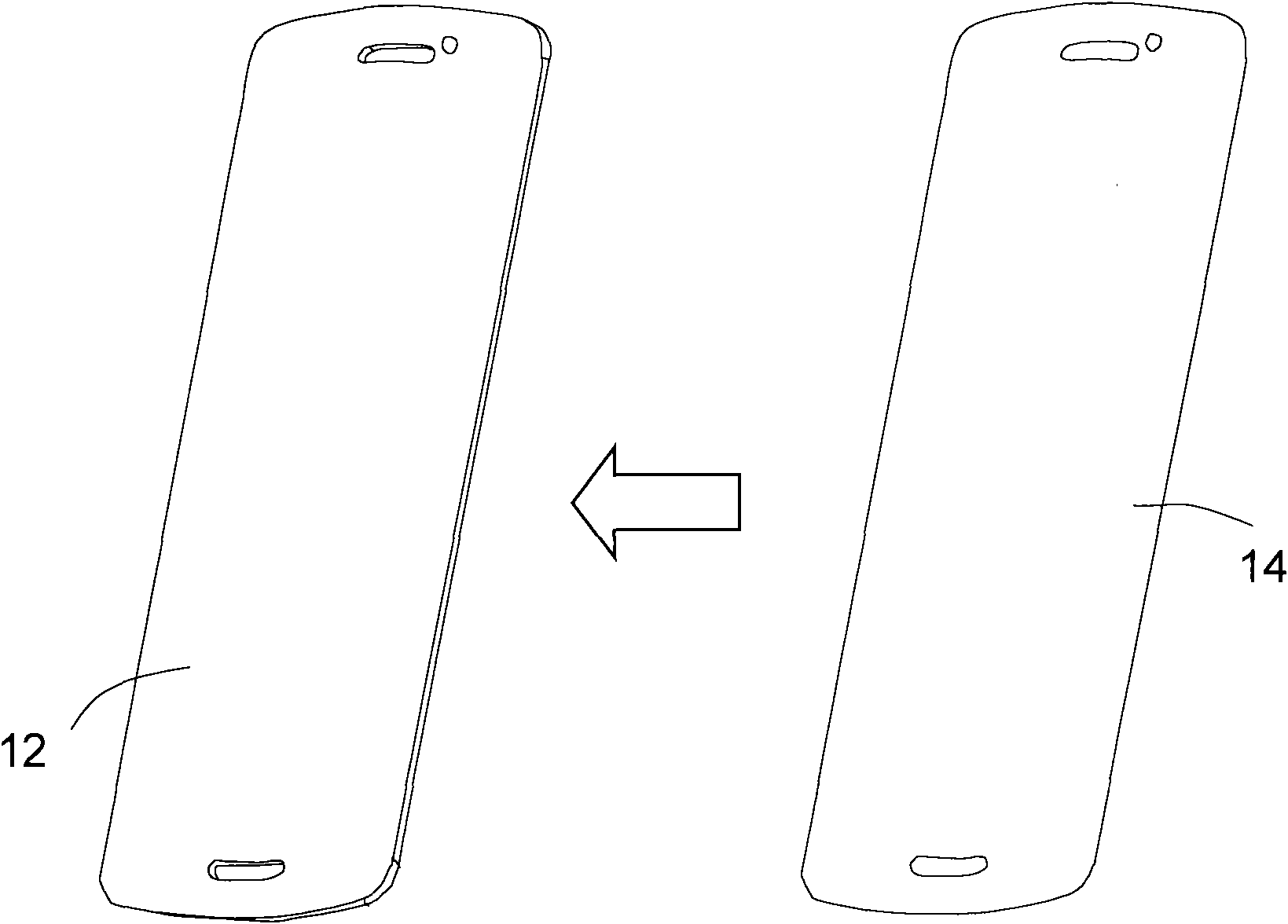

[0017] First, please also refer to the figure 1 , figure 2 and image 3 , which are respectively the front perspective view, rear perspective view and figure 2 Sectional view of the AA line segment. As shown in the figure, the window lens 10 of the present invention mainly includes a glass lens 12 with a light-blocking film 14 pasted on its bottom surface; and a frame 16 wrapped around the glass lens 12, and the material of the frame 16 is plastic.

[0018] The above light blocking film 14 may be made of polybutylene terephthalate (PBT). In addition, at least one positioning hole 18 is provided on the glass lens 12 for positioning the glass lens 12 when the plastic frame 16 is shot.

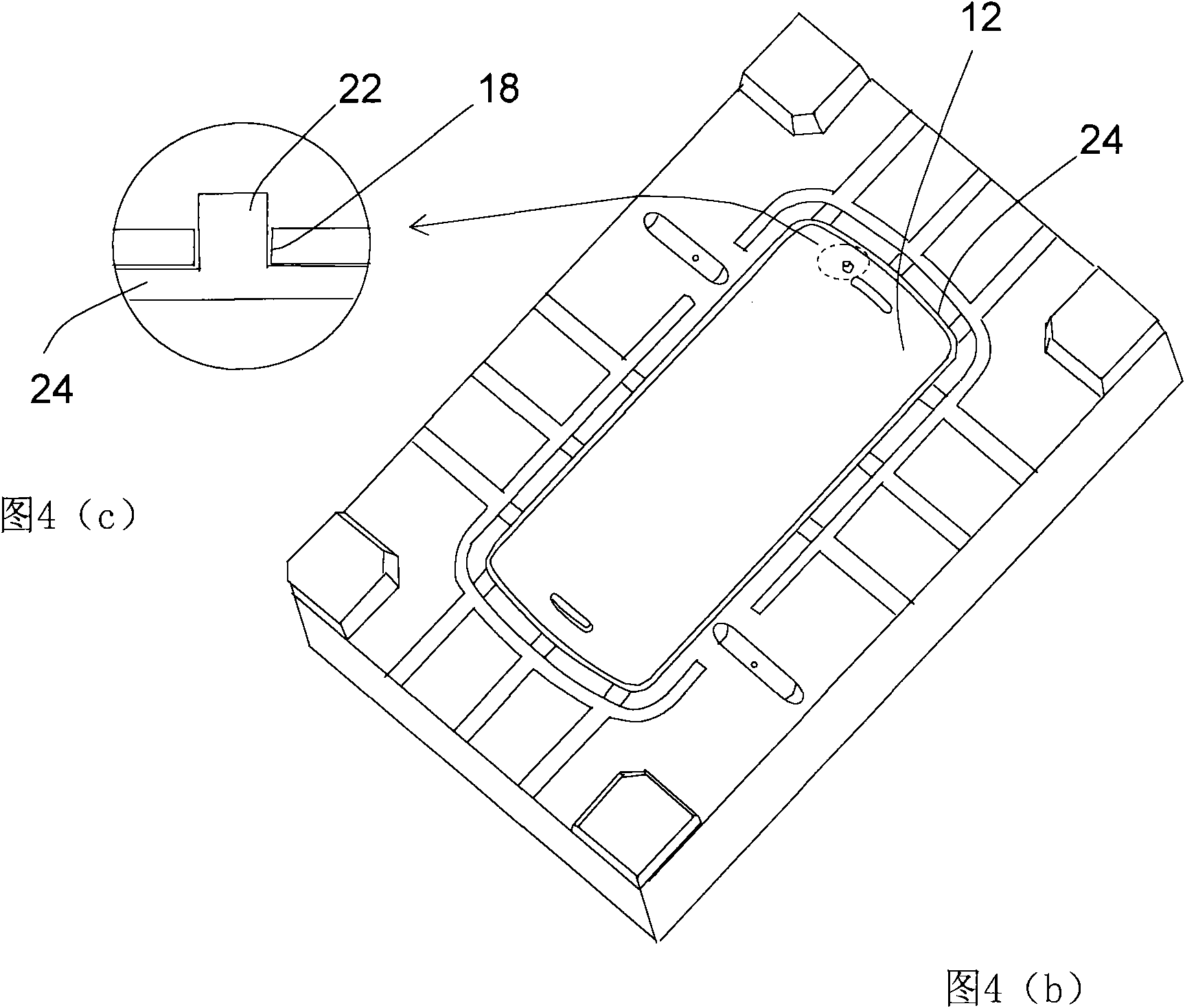

[0019] Next, related descriptions are provided for the manufacturing process of the window lens 10 of the present invention. Please also refer to Figure 4(a) ~ 4(b) and Figure 5 . First, as described in step S1, a glass lens 12 and a light-blocking film 14 are provided, as shown in Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com