Method for making built-in finished product, built-in nut, and built-in finished product

A technology of insert nut and insert molding, which is used in the manufacture of insert molding products, and the fields of insert nuts and insert molding products. It can solve problems such as poor bolt tightening and achieve the effect of preventing wrong installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

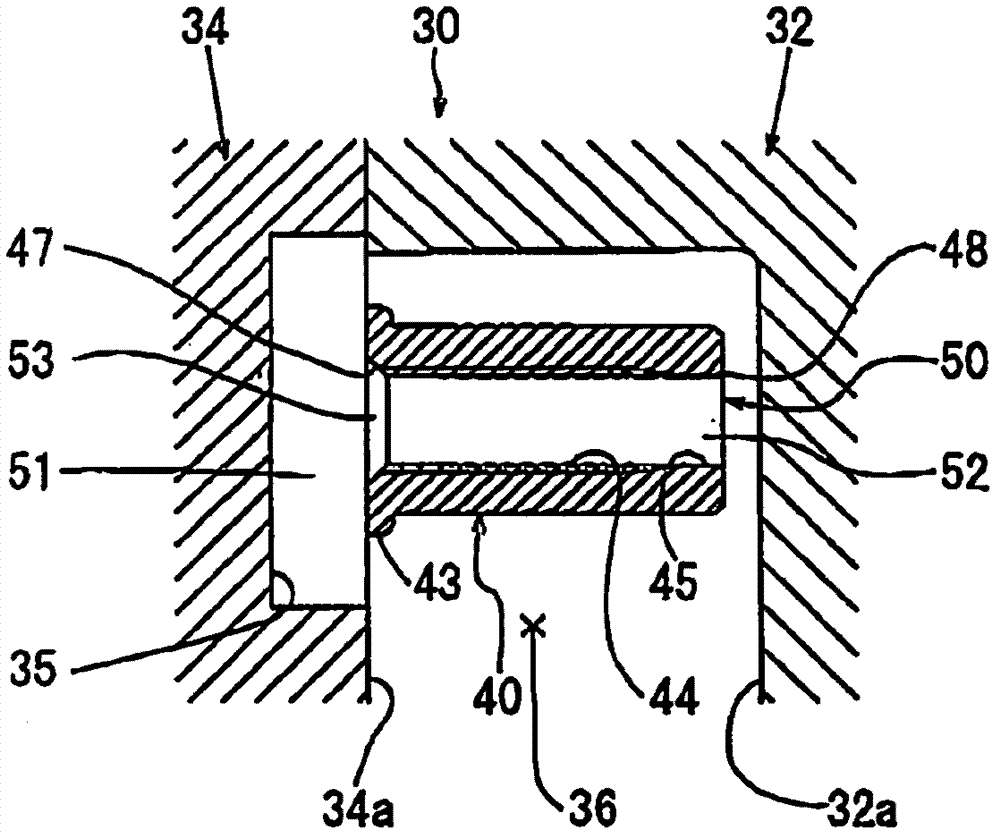

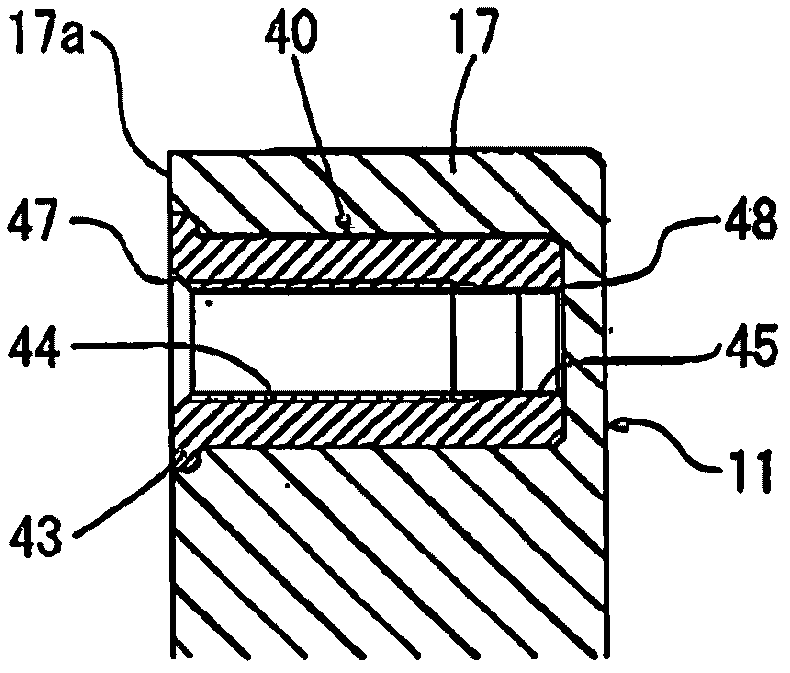

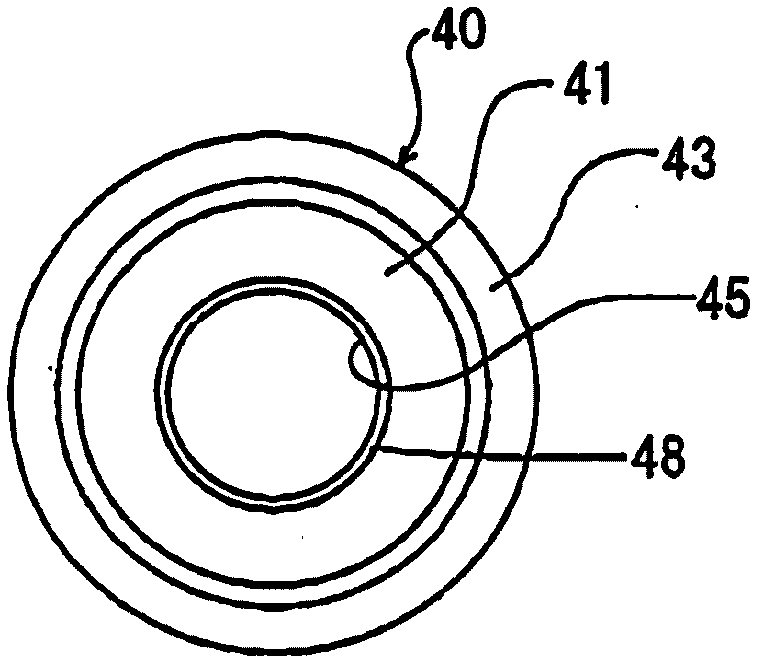

[0021] Embodiments of the present invention will be described below using the drawings.

[0022] One embodiment

[0023] Since this embodiment is applied to an insert-molded product that is one component of a resin-made intake manifold, a method for manufacturing the insert-molded product will be described after explaining the outline of the intake manifold.

[0024] An overview of the intake manifold will be described. In this embodiment, an intake manifold used for an inline four-cylinder engine is exemplified. Figure 8 is a front view showing the intake manifold, Figure 9 It is an exploded side view showing the intake manifold.

[0025] Such as Figure 8 As shown, the intake manifold 10 is four members 11-14 divided into four parts along the front-rear direction by means of vibration welding and other bonding methods (refer to Figure 9 ) combined. That is, if Figure 9 As shown, the intake manifold 10 includes a first member 11 located in the center, and the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com