Fluid detection jig

A technology of fluid detection and fixtures, which is applied in printing and other directions, can solve problems such as time-consuming, and achieve the effects of reducing costs, saving assembly manpower and working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

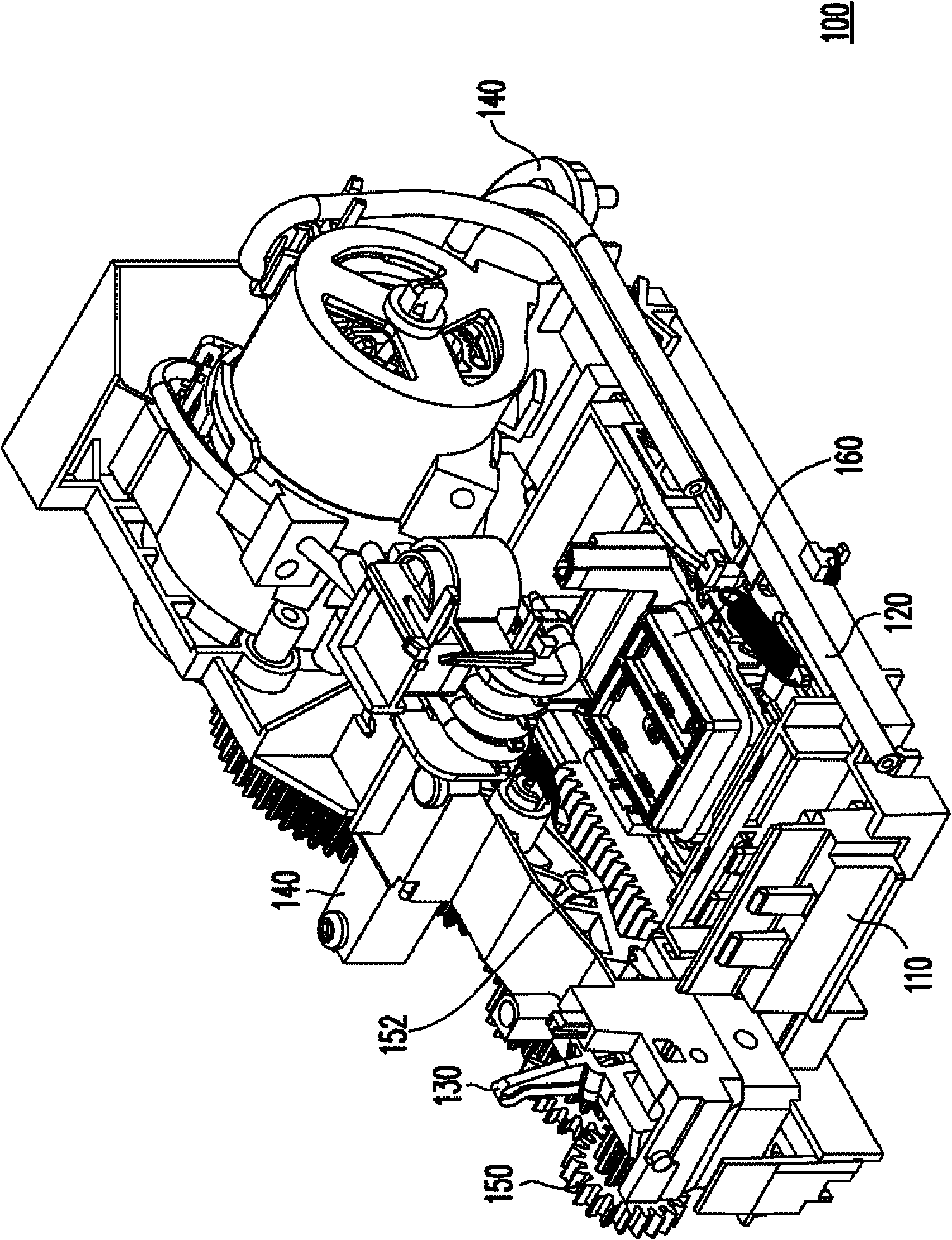

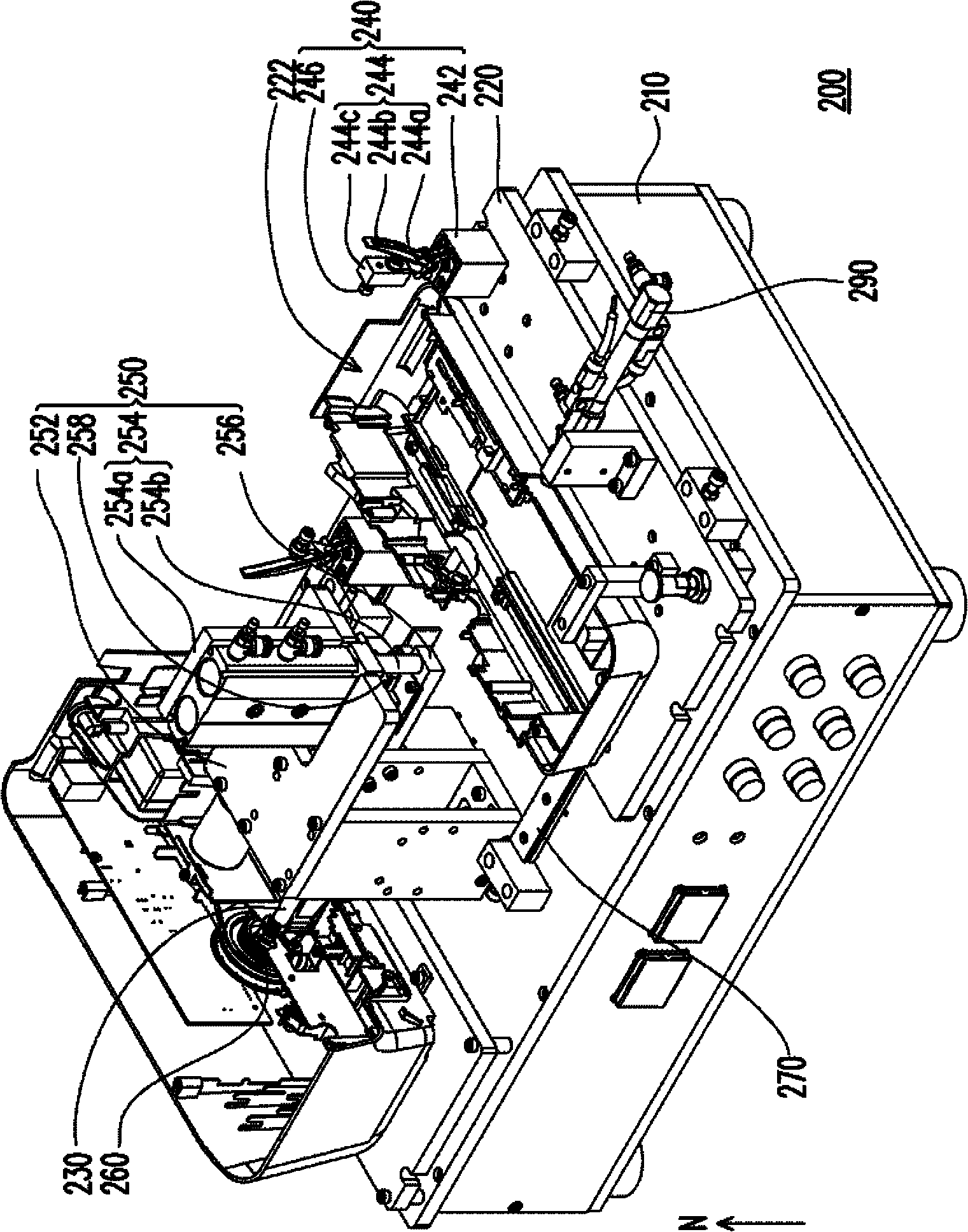

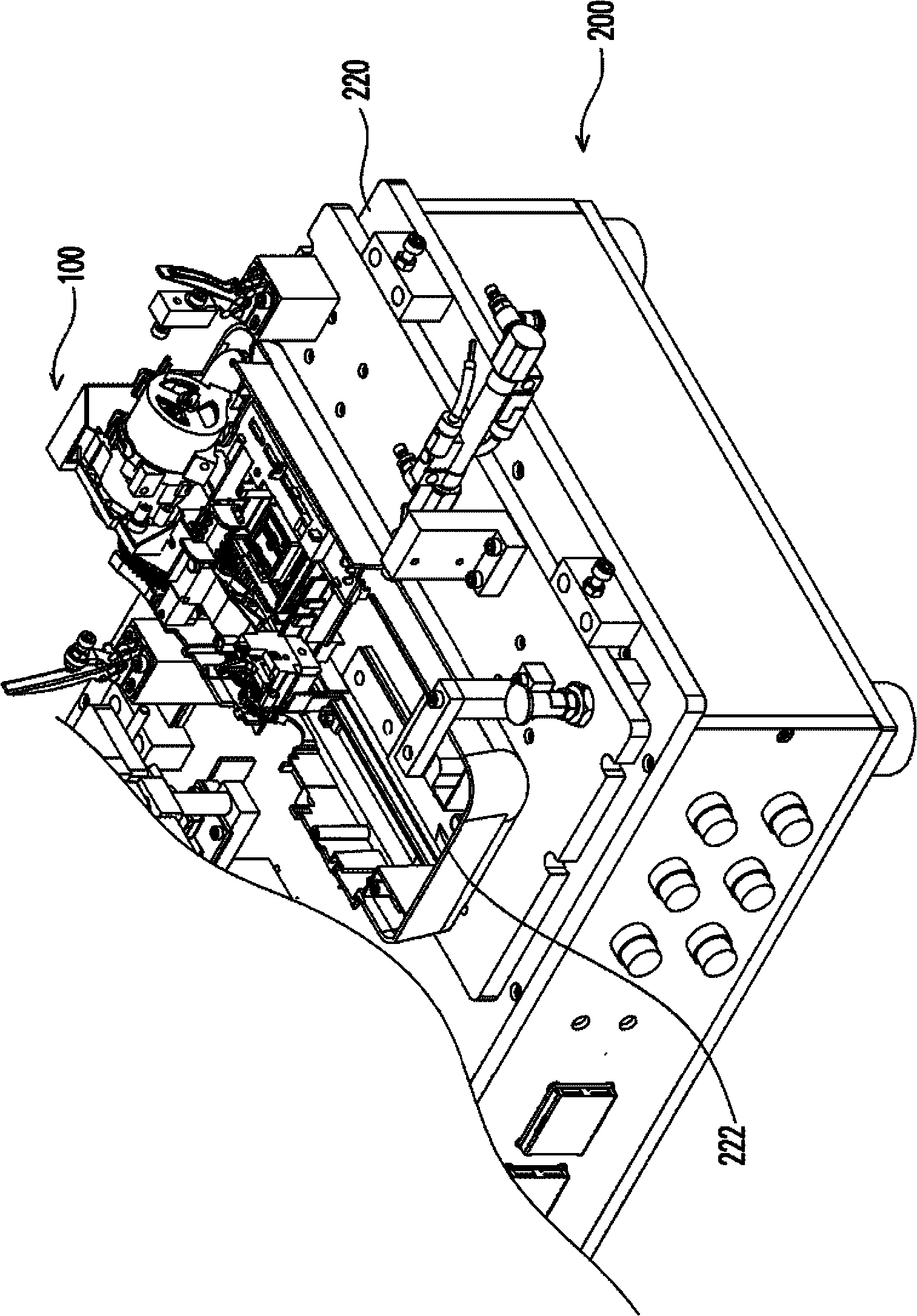

[0067] The fluid detection jig of the present invention is used to test whether the cleaning device can operate and meet the set requirements before the cleaning device is installed in the inkjet printer (or business machine). Before installing the cleaning device on the inkjet printer (or office machine), first use the fluid detection fixture of the present invention to detect the cleaning device, and then install the cleaning device on the inkjet printer (or office machine) after the cleaning device passes the test. or transaction machine). Compared with the known cleaning device that needs to be installed in an inkjet printer (or office machine) before the cleaning device can be tested, the fluid detection jig of the present invention is used to first test the cleaning device, and after the cleaning device passes the test Then it is loaded into the inkjet printer (or business machine), so it can save the assembly manpower and man-hours of disassembly, replacement or repair if...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com