A new type of flatbed car for mounting brackets

A flatbed truck, a new type of technology, used in trucks, transport buses, transportation and packaging, etc., can solve the problems of unstable center of gravity, hidden dangers, and small safety factors, and achieve the effect of eliminating hidden dangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

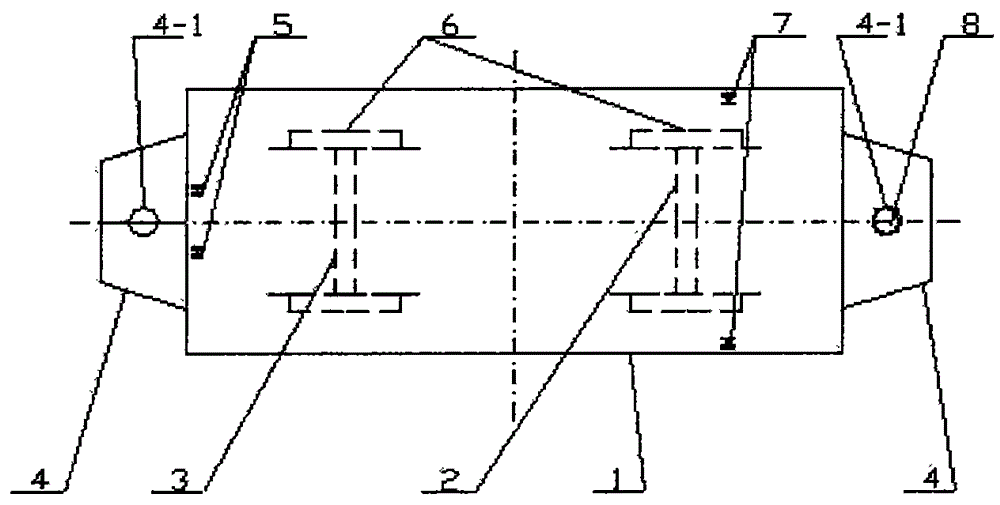

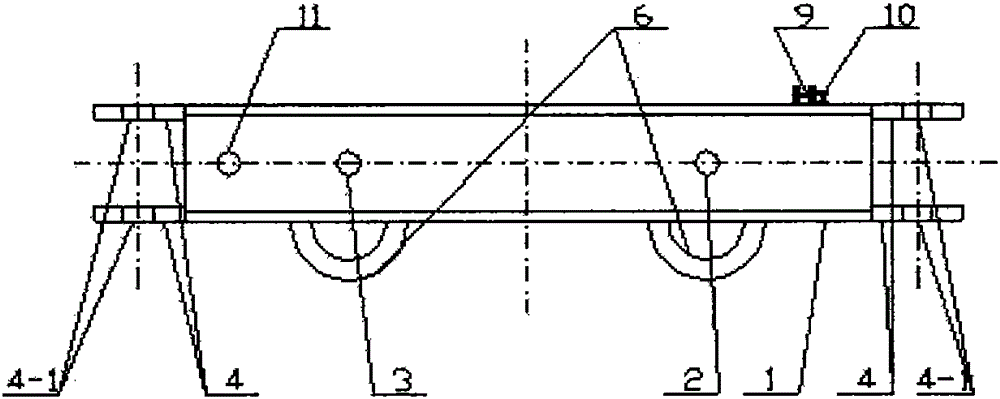

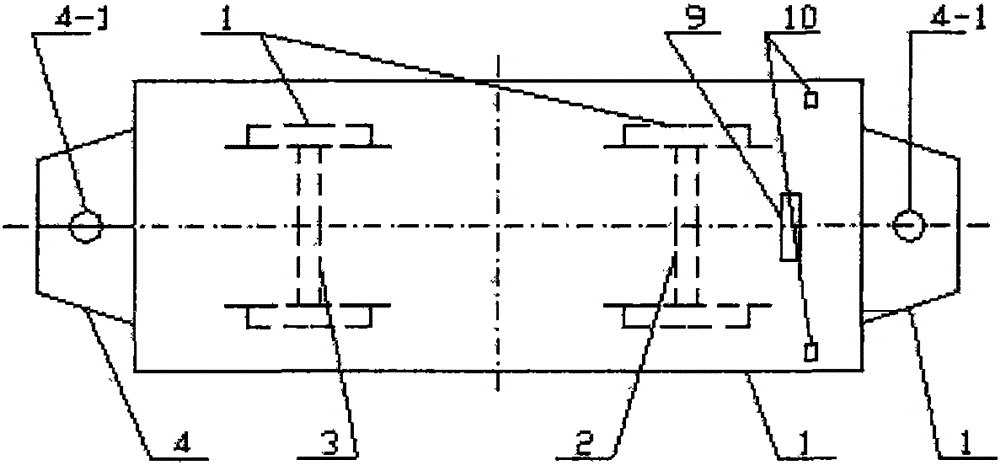

[0011] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment:

[0012] Such as Figure 1-3 As shown, the specific embodiment includes a flatbed vehicle main body 1, a right wheel shaft 2, a left wheel shaft 3, two trapezoidal clamps 4 and wheels 6, and the right wheel shaft 2 and the left wheel shaft 3 are arranged on the bottom of the flat car main body 1 inside, and four wheels 6 They are respectively arranged at the two ends of the right wheel shaft 2 and the left wheel shaft 3, and two trapezoidal clamps 4 are arranged outside the two ends of the flatbed vehicle main body 1, and the trapezoidal clamps 4 are provided with pin holes 4-1; it also includes a bracket top beam fixing device and bracket base fixing device; the bracket top beam fixing device includes the first clamping position I-beam 5, the second clamping position I-beam 7 and bayonet pin 8, the first clamping position I-beam 5 is arranged on the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap