Front mudguard precursor assembly for motorcycle

A technology for front fenders and motorcycles, applied in fenders, bicycle accessories, transportation and packaging, etc., can solve the problems of uneconomical cost and process, affect the sales of this type of model, reduce the grade of the whole vehicle, etc., and achieve the goal of installation Convenience and speed, reduced cost and process complexity, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below by embodiment, in conjunction with accompanying drawing, the present invention is described in further detail:

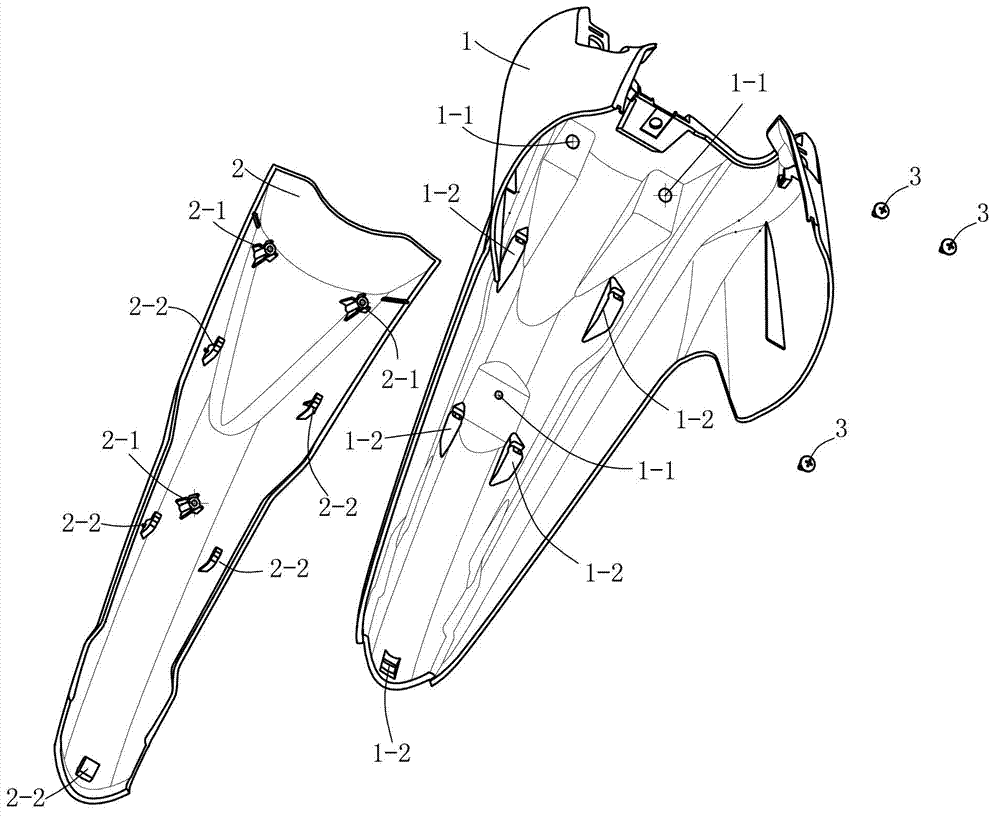

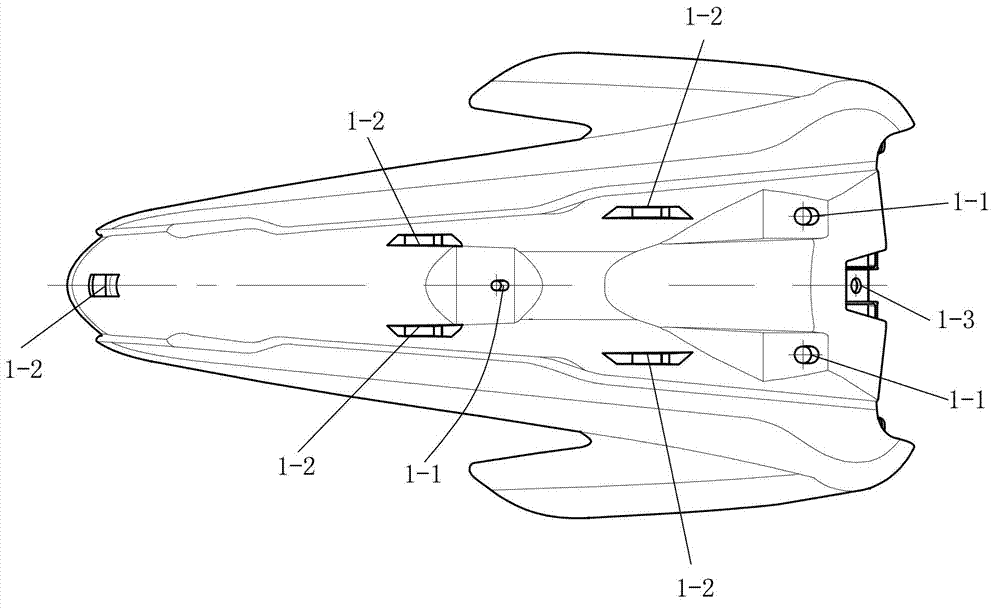

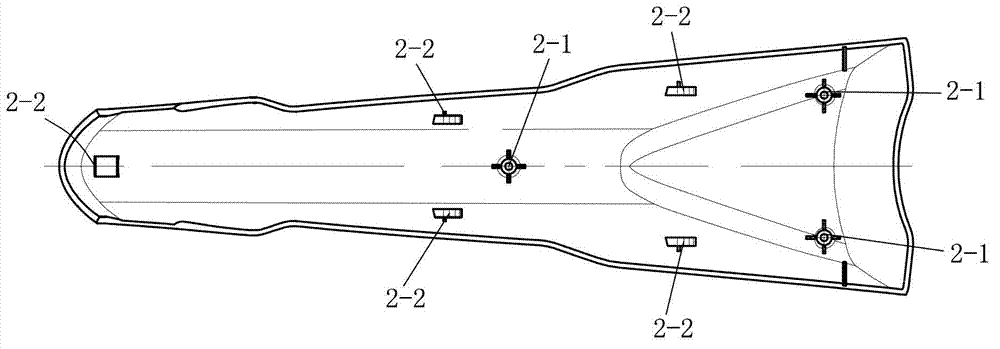

[0013] Such as figure 1 —— image 3 The front fender assembly of the motorcycle shown is composed of a front fender 1 , a front cover 2 made of ABS plastic and three self-tapping screws 3 . The front fender front body 1 can be made of PP plastics or ABS plastics. The front body 1 of the front fender and the front body cover 2 are left-right symmetrical parts, the width of the front body cover 2 is smaller than the width of the front body 1 of the front fender, and the front body cover 2 covers the outside of the front body 1 of the front fender And left and right centrally arranged, when designing, in order to ensure that the front body cover 2 and the front fender front body 1 have a good seam property, the edge of the front body cover 2 should fit together with the front fender front body 1 completely.

[0014] The inner side of the front body cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com