Stretchable turnover box

A turnover box and stretching technology, which is applied in the direction of variable capacity containers, rigid containers, containers, etc., can solve the problems of being fixed, the goods cannot be put into the box, and it is difficult to obtain the turnover box for storage, so as to save storage space. , Simple and easy to assemble, easy to store the effect of fixed shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It will be further described below in conjunction with the embodiments of the drawings.

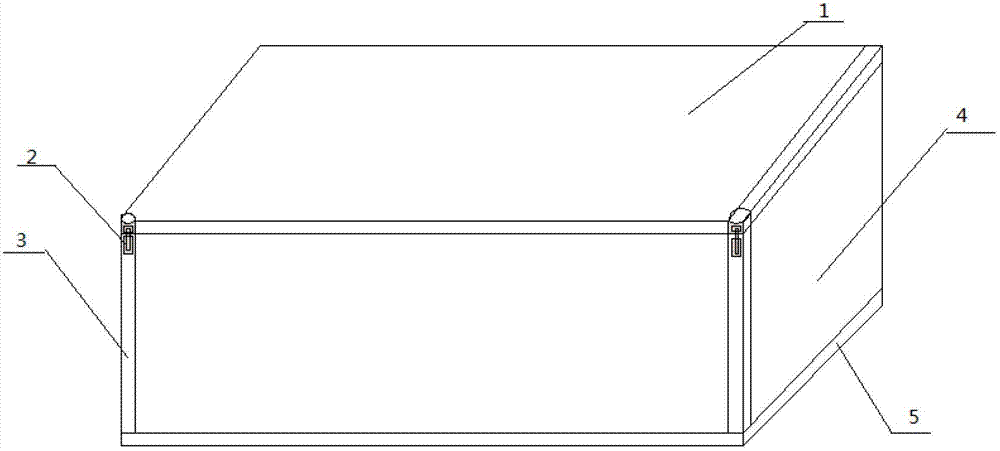

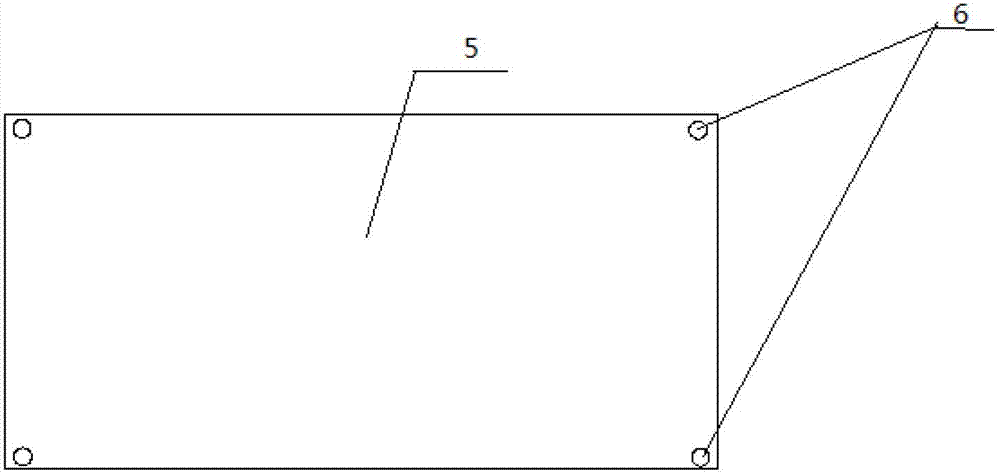

[0020] The present invention is a stretchable turnover box, which is composed of three main parts, a rectangular double-layer bottom plate 5, four stretchable stainless steel pipes 3, and a cover plate 1.

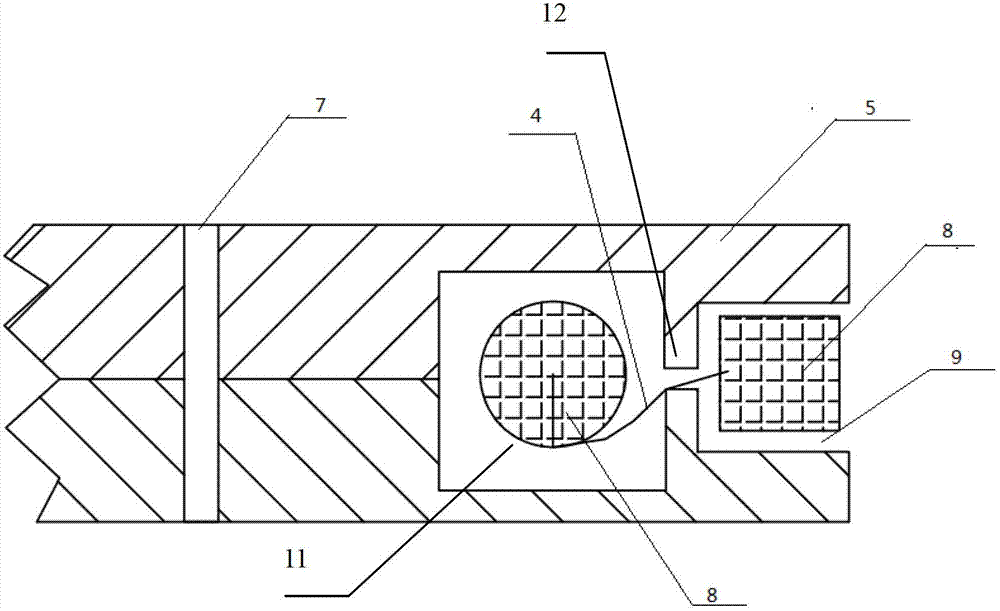

[0021] The bottom plate of the turnover box is composed of double-layer plastic plates. The two plates are riveted by screws 7. The inside of the bottom plate is hollow, and the outside of the four sides is a steel rod storage tank 9. There is a gap 12 between the bottom of the steel rod storage tank and the hollow interior. The two ends of the canvas 4 are fixed with steel rods 8, one end is installed in the steel rod cavity of the bottom plate 5, and the other end is fixed to the steel rod in the steel rod storage tank through the gap; there is a spring device in the steel rod cavity, and the steel rod is in natural state. The lever retracts automatically. When in use, adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com