Detachable annular fuel test assembly

A fuel test and annular technology, applied in the field of reactor engineering, can solve the problems of waste of test resources and research and development funds, and achieve the effect of simplifying the assembly process and assembly process, saving the cycle of component manufacturing and testing, and improving the measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

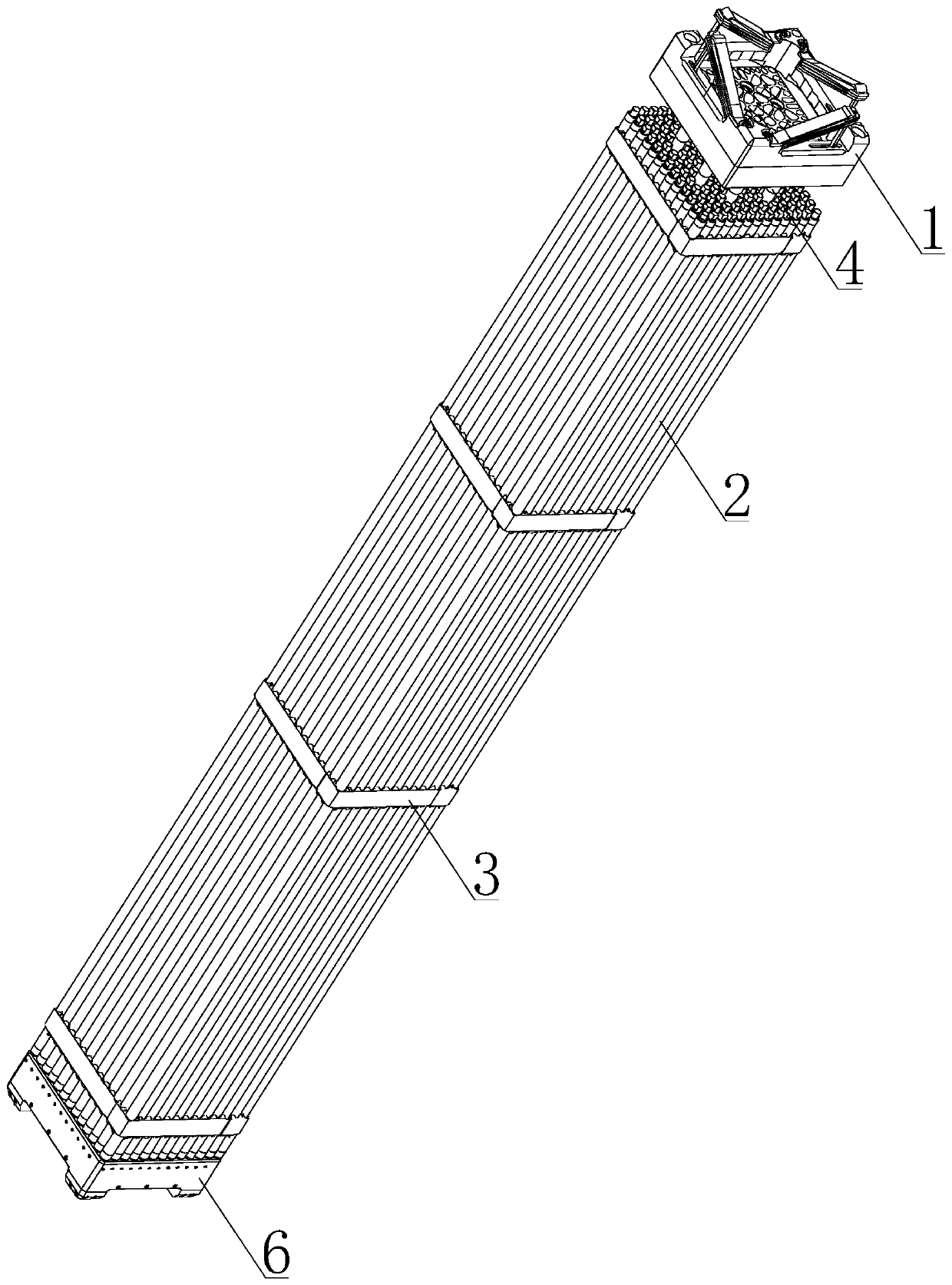

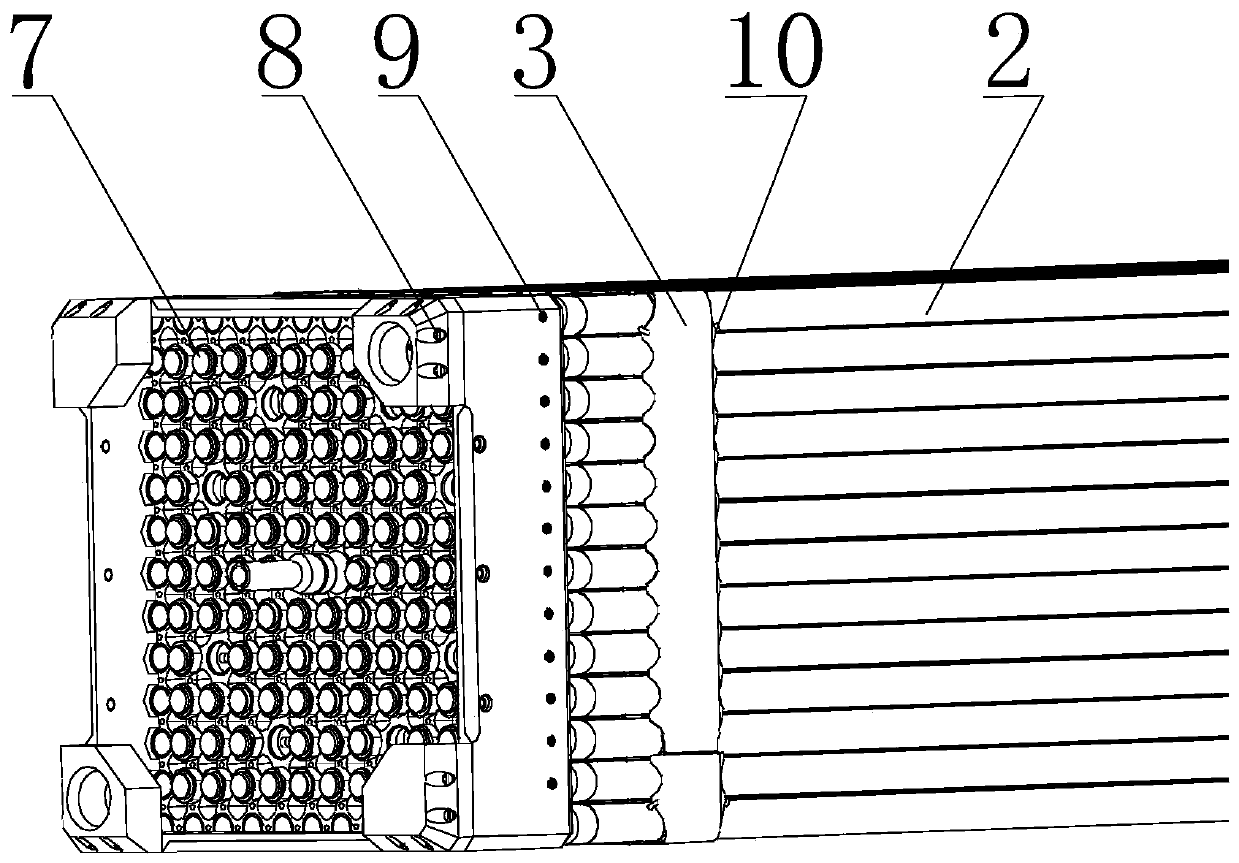

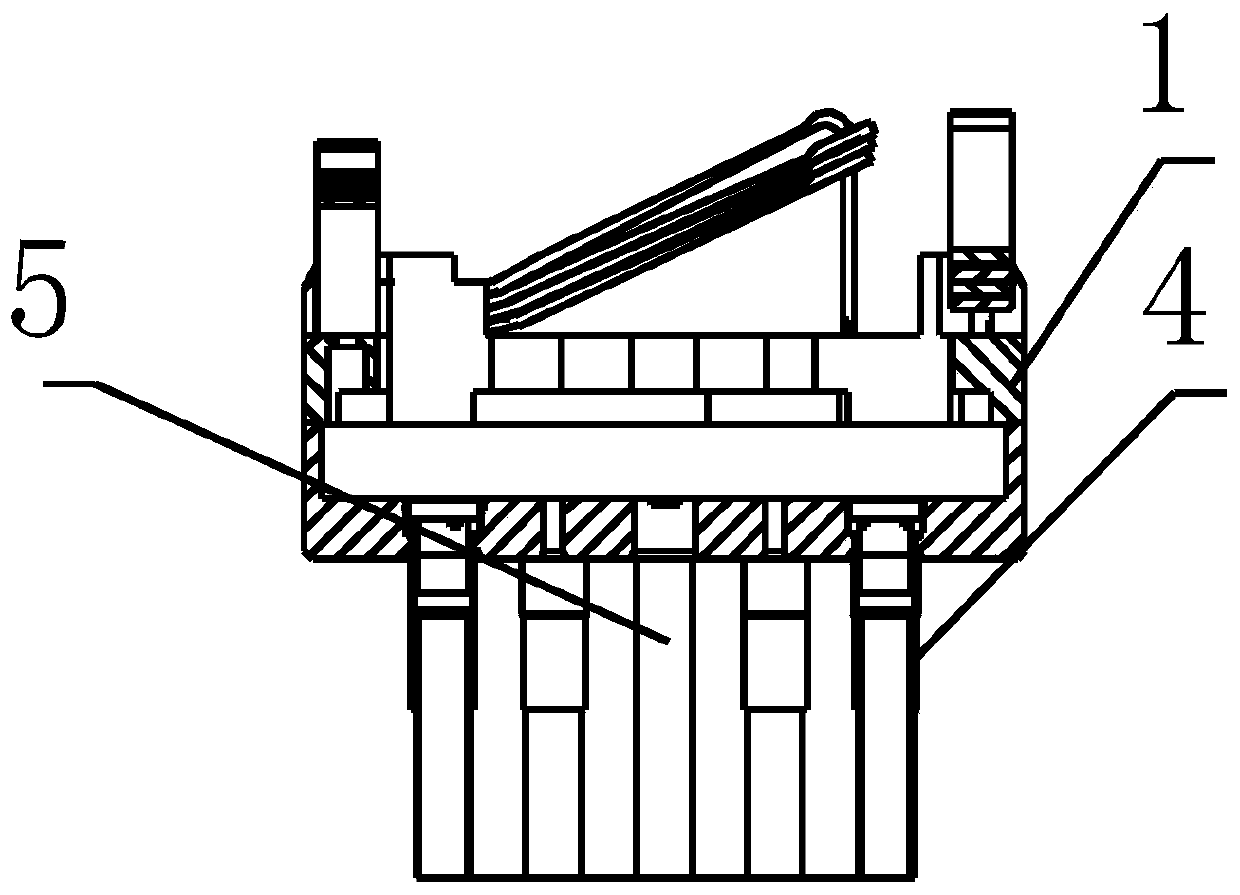

[0041] like figure 1 The shown detachable annular fuel test assembly, suitable for hydraulic simulation test, includes an upper tube seat 1 , an annular fuel simulation rod 2 , a spacer grid 3 , a guide tube 4 , an instrument tube 5 , and a lower tube seat 6 .

[0042] The upper part of the upper tube seat 1 is provided with a compression spring, which cooperates with the upper grid plate of the core to realize the compression of the annular fuel test assembly in the reactor, and can prevent the annular fuel test assembly from moving in the core.

[0043] The annular fuel simulation rod 2 includes an upper end plug, a lower end plug, an inner cladding shell, and an outer shell. The inner cladding shell and the outer shell are coaxially nested, and an upper end plug is arranged above the inner cladding shell and the outer casing, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com