Hydraulic cage stabilizing and supporting wobble platform provided with floating rocker arm

A kind of tank stabilization and hydraulic technology, applied in the direction of lifting equipment, transportation and packaging in mines, can solve the problems of aging structure, large friction resistance, single function, etc., and achieve the effect of compact structure, stable operation and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

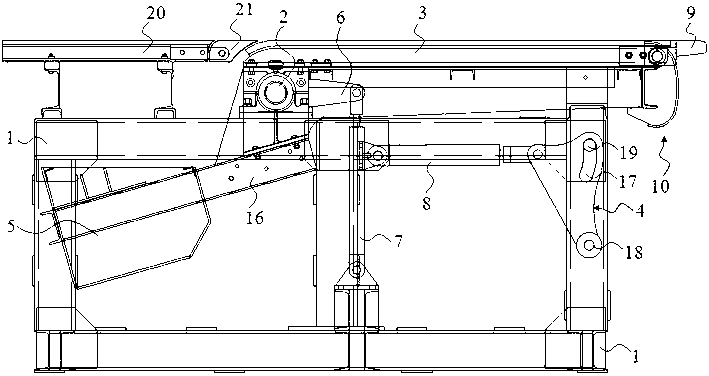

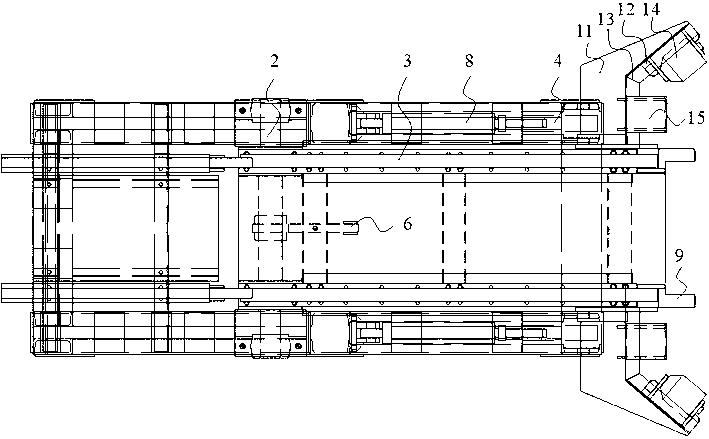

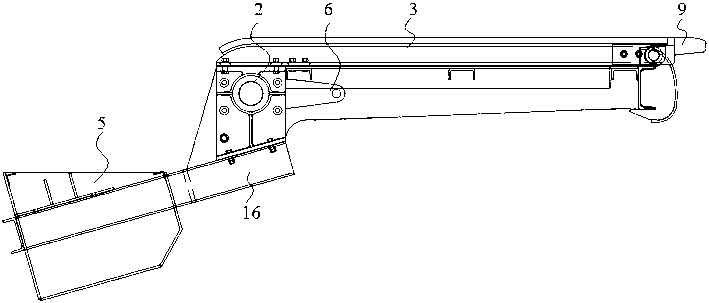

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, the hydraulic tank stabilizing cradle with floating rocker arm of the present invention includes: frame 1, large shaft 2, rocker arm 3, supporting claw 4, adjustable counterweight box 5, driving force arm 6, rocker arm Oil cylinder 7, supporting claw oil cylinder 8, shaking tip 9, tank stabilizer 10 on both sides of the angle. The rocking arm 3 has a pair, is fixed on the top of the frame 1 by the large shaft 2, and the supporting claw 4 is located at the bottom of the front end of the rocking arm 3 and is positioned at both sides of the frame 1. The rocker cylinder 7 is connected to the driving force arm 6 and the base of the frame 1 to drive the rocker 3 to swing up and down. The claw cylinder 8 drives the claw 4 to move along the arc surface. The movement of the rocker cylinder 7 and the claw cylinder 8 passes through the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com