Cutting tool

A technology of cutting tools and working heads, which is applied in the direction of manufacturing tools, metal sawing equipment, metal processing equipment, etc., can solve the problems of difficult lifting and heavy weight for users, and achieve the effect of smooth lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following describes the present invention in detail with reference to the drawings and specific embodiments.

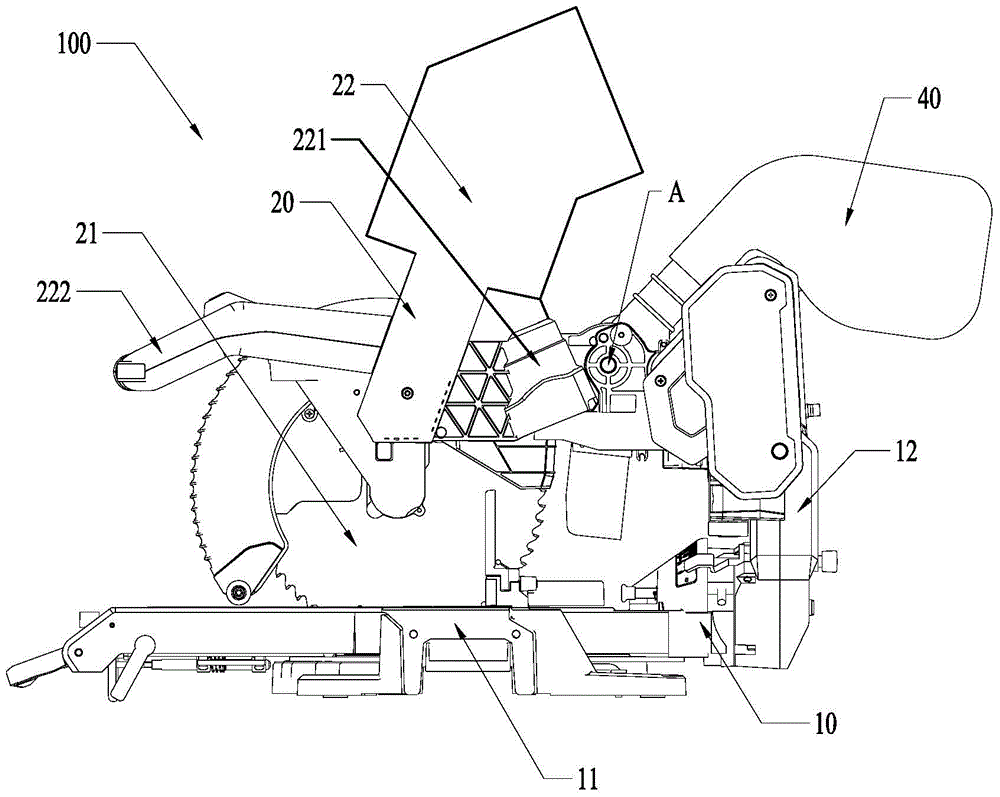

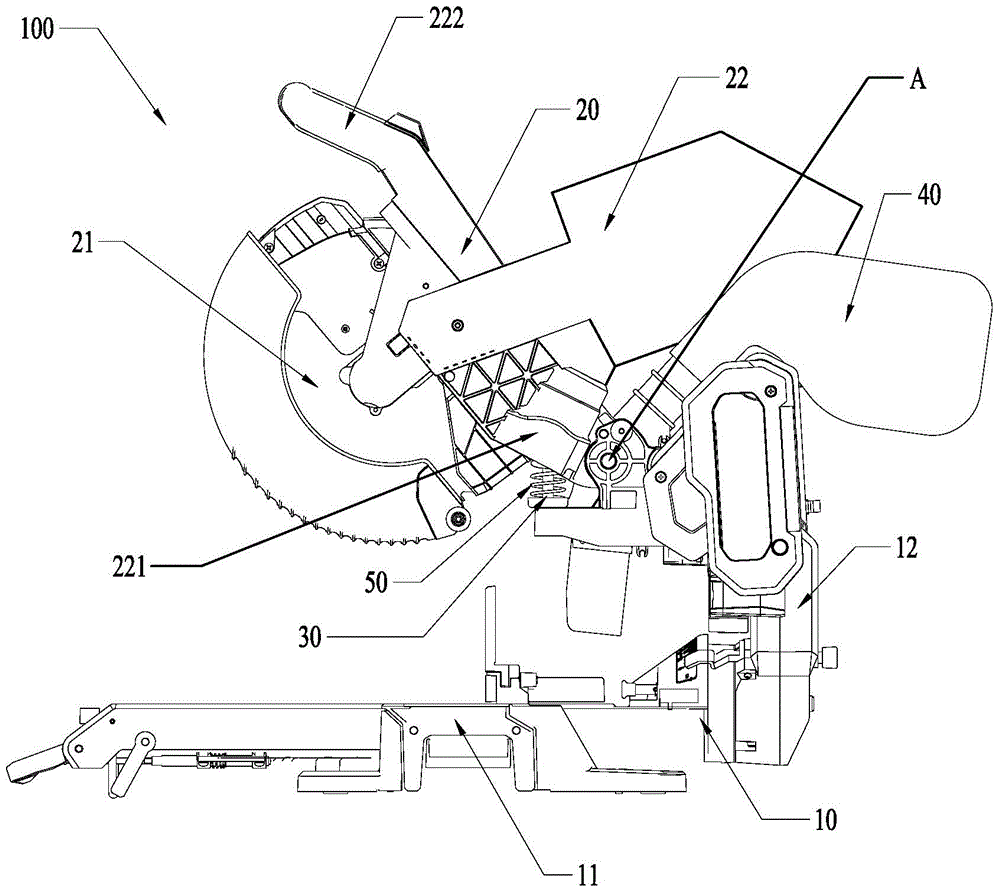

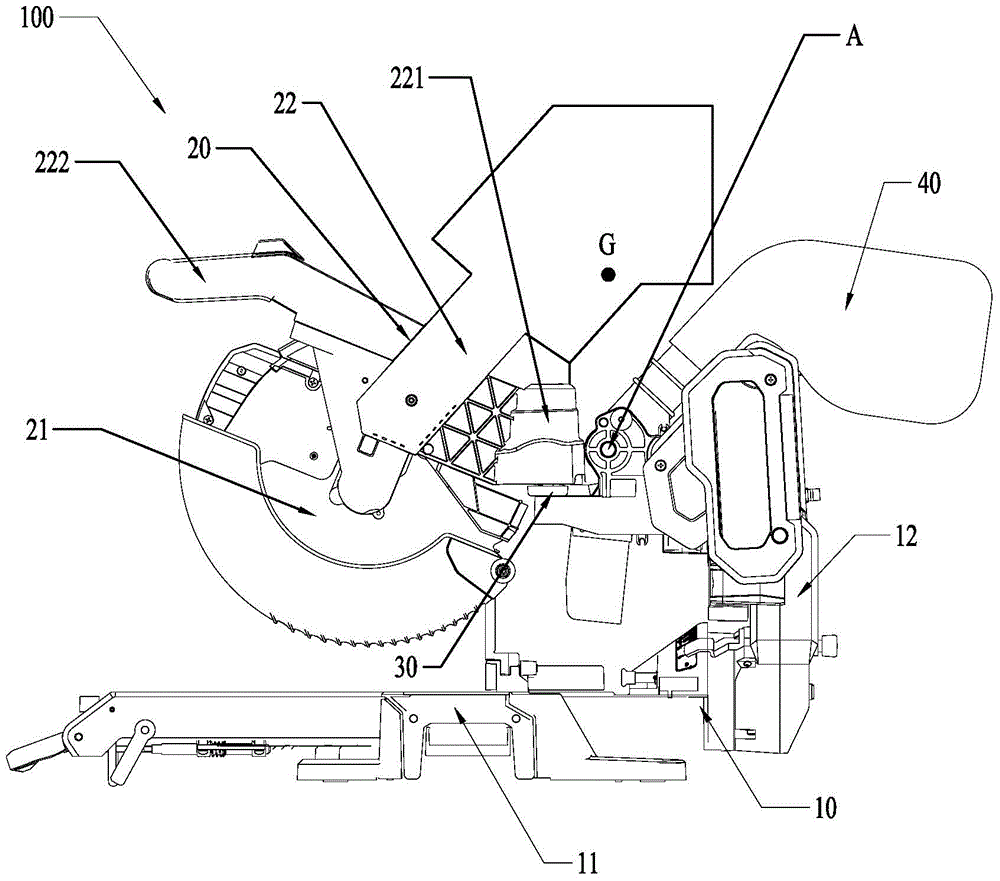

[0025] Reference Figure 1 to Figure 7 As shown, the cutting tool 100 of the present invention includes: a base assembly 10, a cutting head 20, and a bracket assembly assembly 30.

[0026] Wherein, the base assembly 10 includes a base 11 and a rotating bracket 12, and the rotating bracket 12 is arranged above the base 11. Specifically, the base 11 is used to place or position the object to be cut and to support the entire cutting tool 100, and the rotating bracket 12 may be provided on one side of the base 11, which is mainly used to connect the cutting head 20 and, for example, dust suction Component 40 and other structures. It should be noted that if the cutting tool 100 of the present invention is a miter saw, the rotating bracket 12 can form a rotating connection with the base 11 with an axis parallel to the saw blade 21 to realize the miter cutting functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com