Multi-stage lifting and feeding device of automatic bamboo breaking machine

A technology of lifting device and feeding device, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problem that the bamboo tube stacking area cannot be stacked, and achieve the effect of stable lifting and conveying process, saving processing man-hours, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

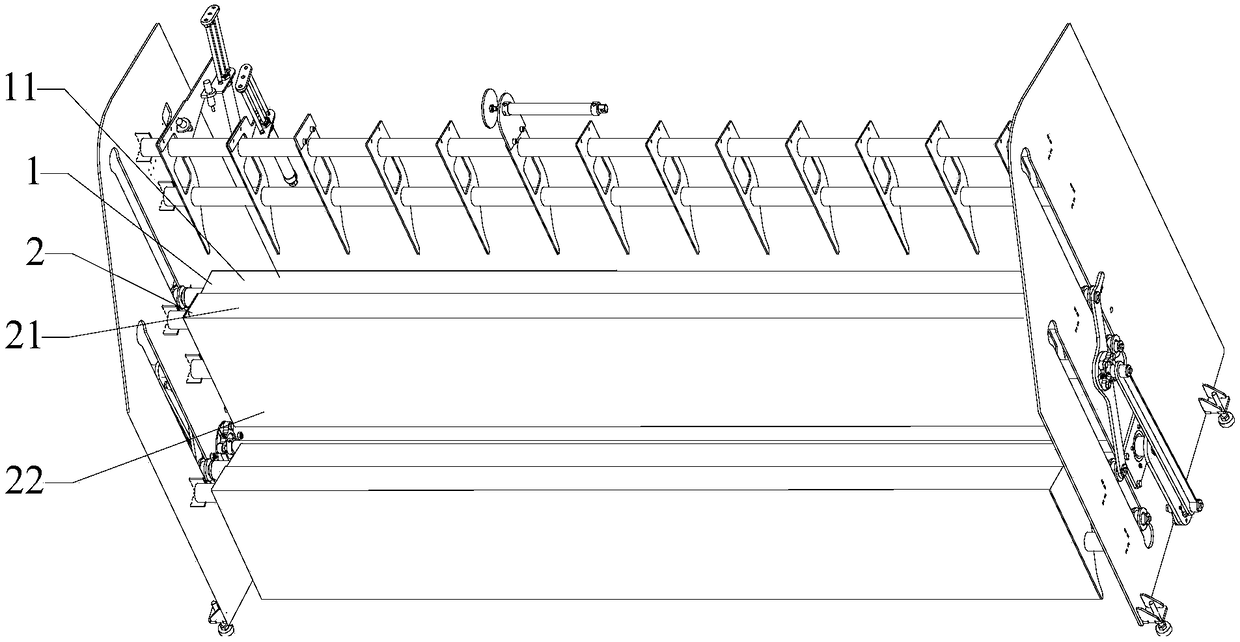

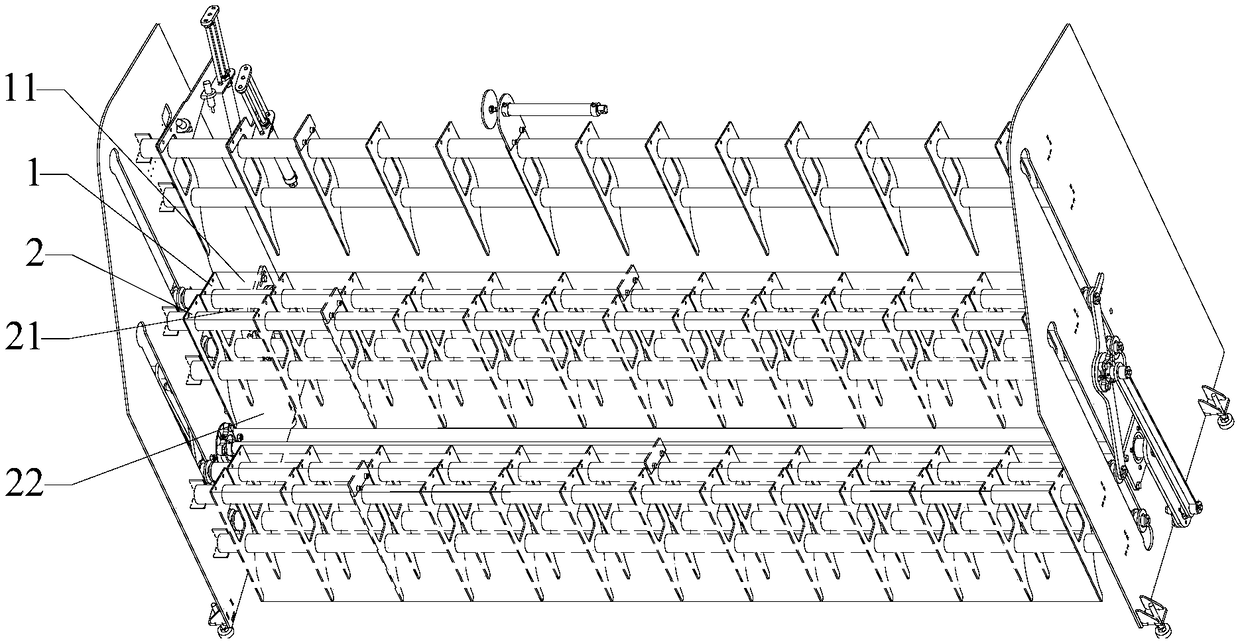

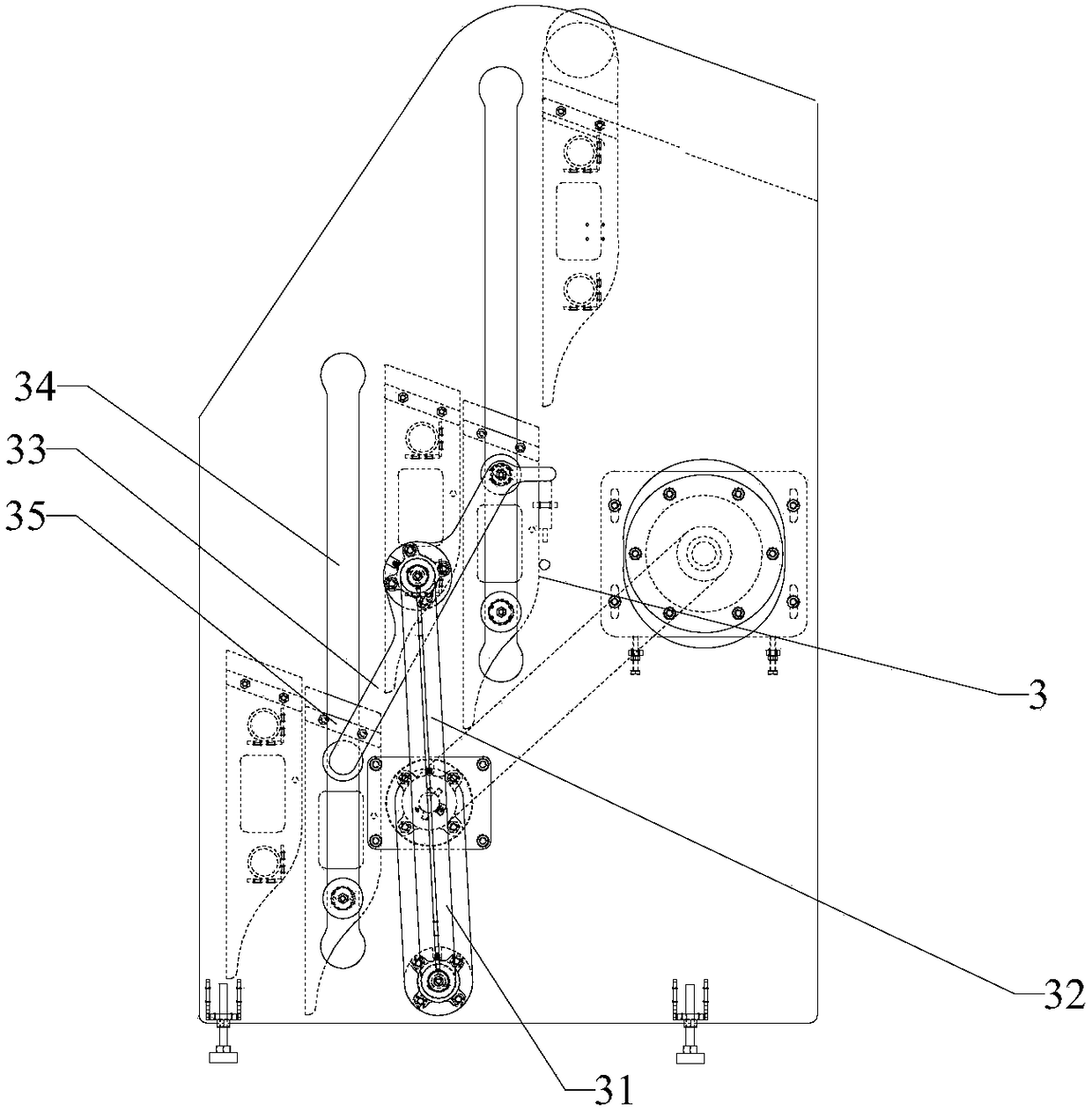

[0030] A multi-stage lifting and feeding device for an automatic bamboo breaking machine, comprising a lifting device body and a driving device 3, the lifting device body includes a plurality of lifting device monomers, and the lifting device monomers and adjacent lifting device monomers form steps distribution, the lifting device includes a fixed part 2 and a lifting part 1, and the lifting part 1 includes a lifting plate 11 that moves vertically; the fixing part 2 includes a side plate 22 and a guide plate 21; the guide plate 21 Located on the outside of the lifting plate 11, the guide plate 21 is a first slope inclined towards the lifting plate 11, the upper end of the side plate 22 is connected to the upper end of the first slope, and the lifting plate 11 is located at the lower end of the first slope The upper surface of the lifting plate 11 is a second slope identical to the first slope; the shape of the first slope is a rectangle; the shape of the second slope is a recta...

Embodiment 2

[0032] A multi-stage lifting and feeding device for an automatic bamboo breaking machine according to Embodiment 1, further comprising a stacking rack for stacking bamboo tubes to be processed; the stacking rack is connected to the body of the lifting device.

[0033]In summary, in the structure of the multi-stage lifting and feeding device of the automatic bamboo breaking machine involved in the present invention, the multi-stage lifting device unit is arranged in a stepped manner, and the bamboo tube is automatically rolled to the top of the lifting plate through the slope, and the bamboo tube is lifted by the lifting plate. Lift to the upper level lifting device monomer, automatically roll to the upper lifting plate of the upper level lifting device monomer, to achieve the purpose of automatic lifting and conveying of bamboo tubes; the multi-level lifting feeding device of the automatic bamboo breaking machine involved in the present invention is compared with the prior art ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com