A protective agent for protecting rusted art steel plates

A protective agent, steel plate technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of uncontrollable corrosion effect of rusted art steel plates and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

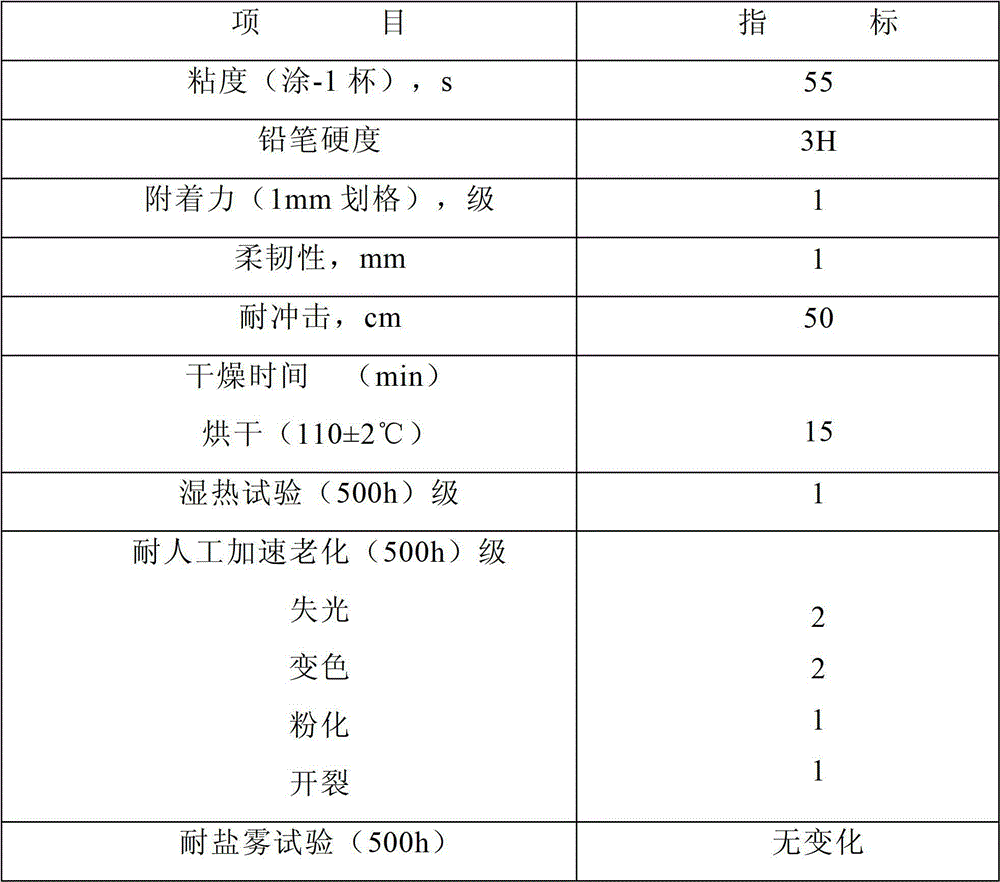

[0022] Put 60 grams of water-based polyurethane dispersion into the paint mixing tank, add 1 gram of ammonia water to adjust the pH value, add 3 grams of isopropanol, 25 grams of ethylene glycol butyl ether, 2 grams of BYK-345, 3 grams of BYK-333, and stir After uniformity, the protective agent solution is obtained, and the sample is coated on the surface of the steel plate model, and then quickly dried to form a film. After the performance test (parameters are shown in Table 1), it is filtered and packaged.

[0023] Table 1

[0024]

[0025] In the above examples, the water-based resin (water-based polyurethane dispersion) accounts for 64% of the weight of the total protective agent, the PH value adjustment aid (ammonia water) accounts for 1% of the weight of the total protective agent, and the coating additives (BYK-345 and BYK- 333) accounts for 5% of the total weight of the protective agent, and the solvent (isopropanol and ethylene glycol butyl ether) accounts for 30% ...

Embodiment 2

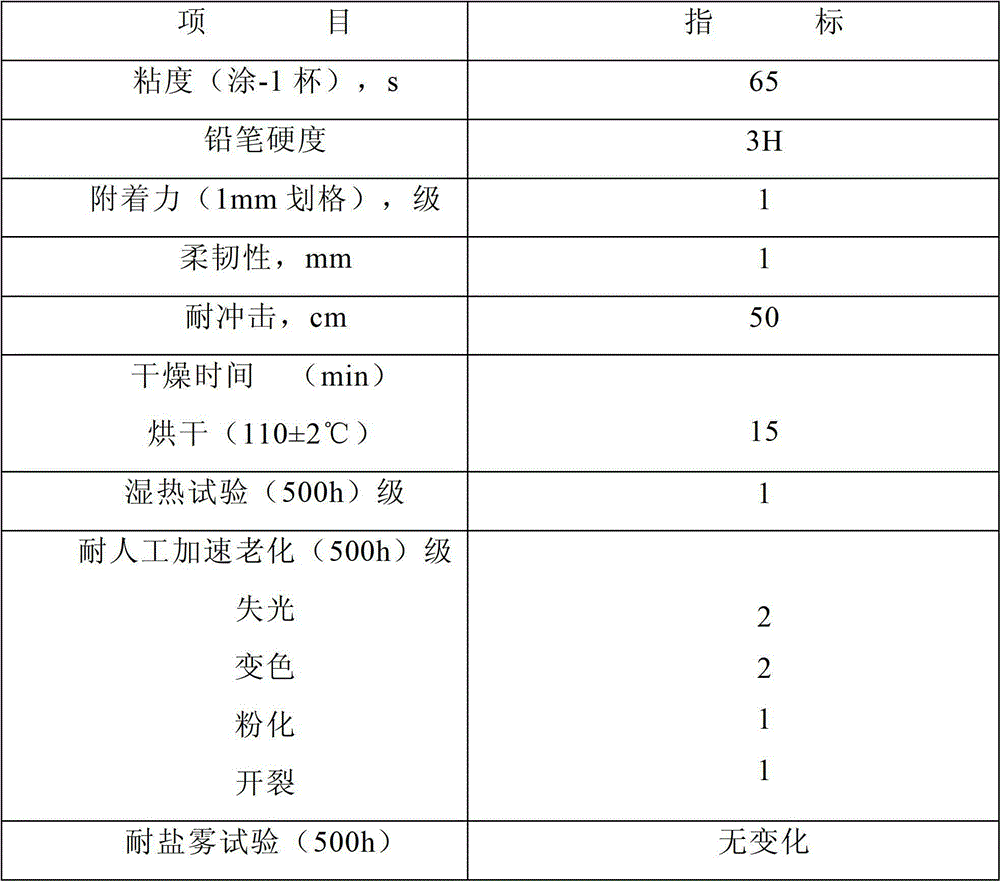

[0028] Add 159 grams of water-based acrylic emulsion to the paint mixing tank, stir evenly, add 4 grams of dimethylethanolamine to adjust the pH value, add 3 grams of isopropanol, 20 grams of ethylene glycol butyl ether, and 6 grams of ethylene glycol butyl ether acetate , 2 grams of ethylene glycol phenyl ether, 2 grams of BYK-345, 2 grams of BYK-333, and 2 grams of matting agent are stirred evenly to obtain a protective agent solution. The sample is coated on the surface of the steel plate and then quickly dried to form a film. Filter and pack after passing the test (parameters in Table 2).

[0029] Table 2

[0030]

[0031] In the above examples, the water-based resin (water-based acrylic emulsion) accounts for 80% of the weight of the total protective agent, the pH value adjustment assistant (dimethylethanolamine) accounts for 2% of the weight of the total protective agent, and the paint additives (BYK-345, BYK-333 and matting agent) account for 3% of the total weight ...

Embodiment 3

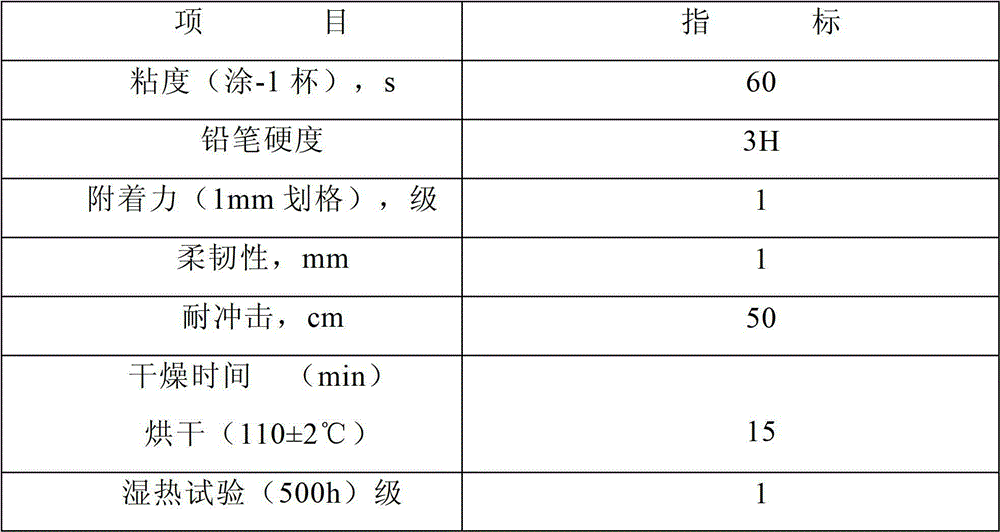

[0034] Add 90 grams of water-based polyurethane dispersion and 70 grams of water-based acrylic emulsion into the paint mixing tank, stir evenly, add 8 grams of ammonia water to adjust the pH value, add 4 grams of isopropanol, 25 grams of ethylene glycol butyl ether, and 3 grams of ethylene glycol Butyl ether acetate, 5 grams of ethylene glycol phenyl ether, 4 grams of BYK-345, 4 grams of BYK-333, and 4 grams of matting additives are stirred evenly to obtain a protective agent solution. Samples are coated on the surface of the steel plate and then quickly baked. Dry to form a film, filter and pack after passing the performance test (parameters in Table 3).

[0035] table 3

[0036]

[0037]

[0038] In the above-mentioned embodiment, the water-based resin (water-based polyurethane dispersion and water-based acrylic emulsion) accounts for 74% of the total protective agent weight, the PH value adjustment assistant (ammonia water) accounts for 4% of the total protective agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com