A kind of antifouling externally pasted inorganic board and preparation method thereof

An inorganic board, anti-fouling technology, applied in the field of outdoor building decoration materials, can solve the problems of water marks, affecting the decoration effect, etc., and achieve the effect of solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

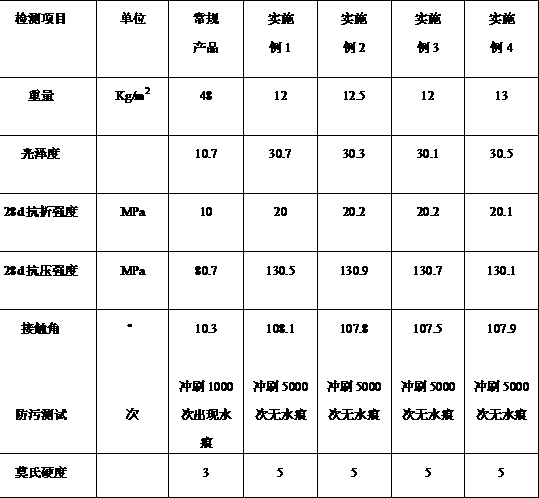

Examples

Embodiment 1

[0022] Inorganic gelling material 28.5%, reinforcing material 2%, dispersible rubber powder 1.2%, dispersant 2%, shrinkage reducing agent 1.3%, water reducing agent 1.3%, defoamer 0.8%, coagulant 1.4%, papermaking white mud 21%, hydrophobic agent 3.5%, filler 30.3%, water 6%, colorant 0.7%. Among them, the inorganic gel material is composed of the following components by weight percentage: 52.5 white Portland cement 60%, ferric aluminate cement 16%, Bossier cement 13%, clay 11%; the reinforcing material is glass fiber; dispersible The rubber powder is composed of the following components by weight percentage: polyacrylamide 32%, polyethylene glycol ether 21%, polyethylene oxide 35%, polyvinylpyrrolidone 12%; the dispersant is composed of the following components by weight percentage: hydroxyethyl Cellulose 37%, hydroxyethyl methyl cellulose 46%, hydroxybutyl methyl cellulose 17%; shrinkage reducing agent is composed of the following components by weight percentage: ethylene ox...

Embodiment 2

[0024] Inorganic gelling material 30.1%, reinforcing material 2%, dispersible rubber powder 1.8%, dispersant 1.5%, shrinkage reducing agent 1.5%, water reducing agent 1.6%, defoaming agent 1.1%, coagulant 1.2%, papermaking white mud 20%, hydrophobic agent 4.2%, filler 27.1%, water 7%, colorant 0.9%. Among them, the inorganic gel material is composed of the following components by weight percentage: 52.5 white Portland cement 71%, ferroaluminate cement 16%, and clay 13%; the reinforcing material is glass fiber; the dispersible rubber powder is composed of the following weight percentage The composition of the composition: polyacrylamide 41%, polyethylene oxide 32%, polyvinylpyrrolidone 17%; the dispersant is composed of the following components by weight percentage: hydroxyethyl cellulose 43%, hydroxyethyl methyl cellulose 28% %, hydroxybutyl methyl cellulose 29%; the shrinkage reducer is composed of the following components by weight percentage: ethylene oxide propylene oxide ...

Embodiment 3

[0026]Inorganic gelling material 26.9%, reinforcing material 2%, dispersible rubber powder 1.8%, dispersant 1.2%, shrinkage reducing agent 2.1%, water reducing agent 1.9%, defoaming agent 1.5%, coagulant 1.7%, papermaking white mud 21.8%, hydrophobic agent 6%, filler 25.3%, water 7%, colorant 0.8%. Among them, the inorganic gel material is composed of the following components by weight percentage: 52.5% white Portland cement 56%, ferroaluminate cement 35%, clay 9%; the reinforcing material is glass fiber; the dispersible rubber powder is composed of the following weight percentage Composition: 32% polyacrylamide, 35% polyethylene glycol ether, 18% polyethylene oxide, 15% polyvinylpyrrolidone; the dispersant is composed of the following components by weight: 43% hydroxyethyl cellulose, hydroxyethyl cellulose Hydroxybutyl methyl cellulose 17%, hydroxybutyl methyl cellulose 40%; shrinkage reducing agent is composed of the following components by weight percentage: ethylene oxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com