Pulling-resistant frictional oscillating support for seismic reduction and isolation

A seismic isolation and pullout-resistant technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of lack of pullout resistance, limited sliding displacement, and inability to grade seismic fortification, and achieve easy design selection and optimization, large sliding Displacement capacity, the effect of reducing seismic action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

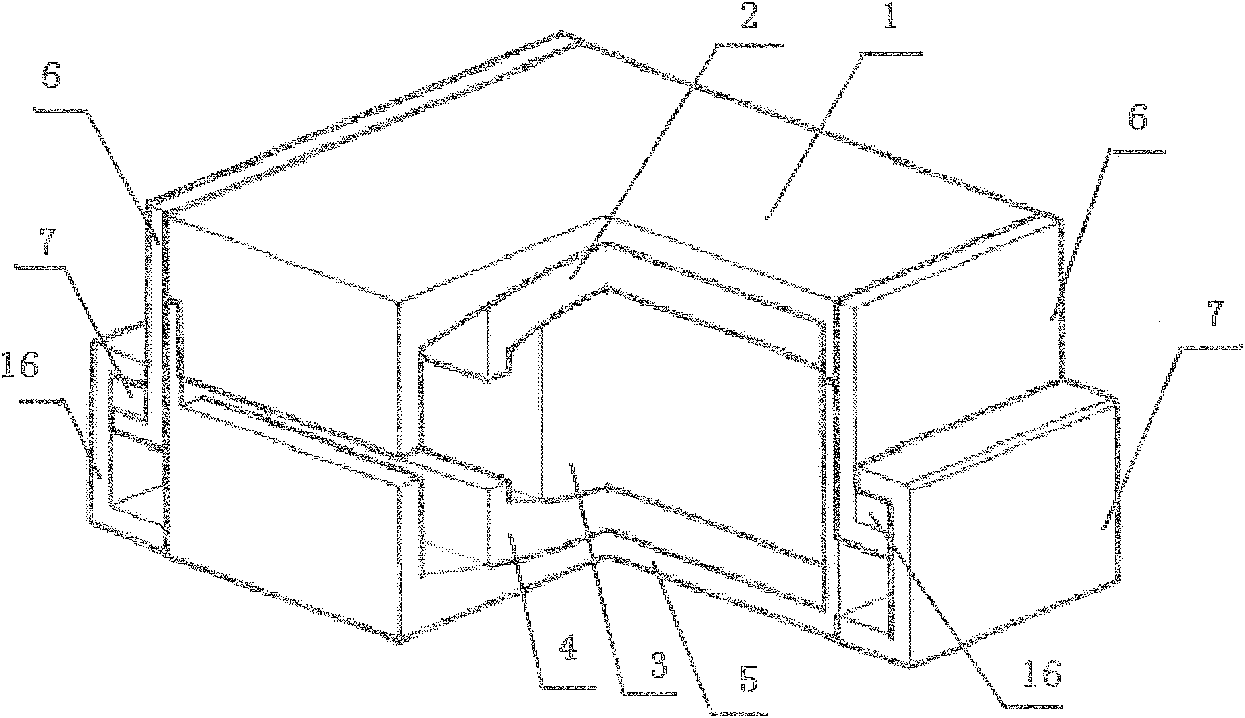

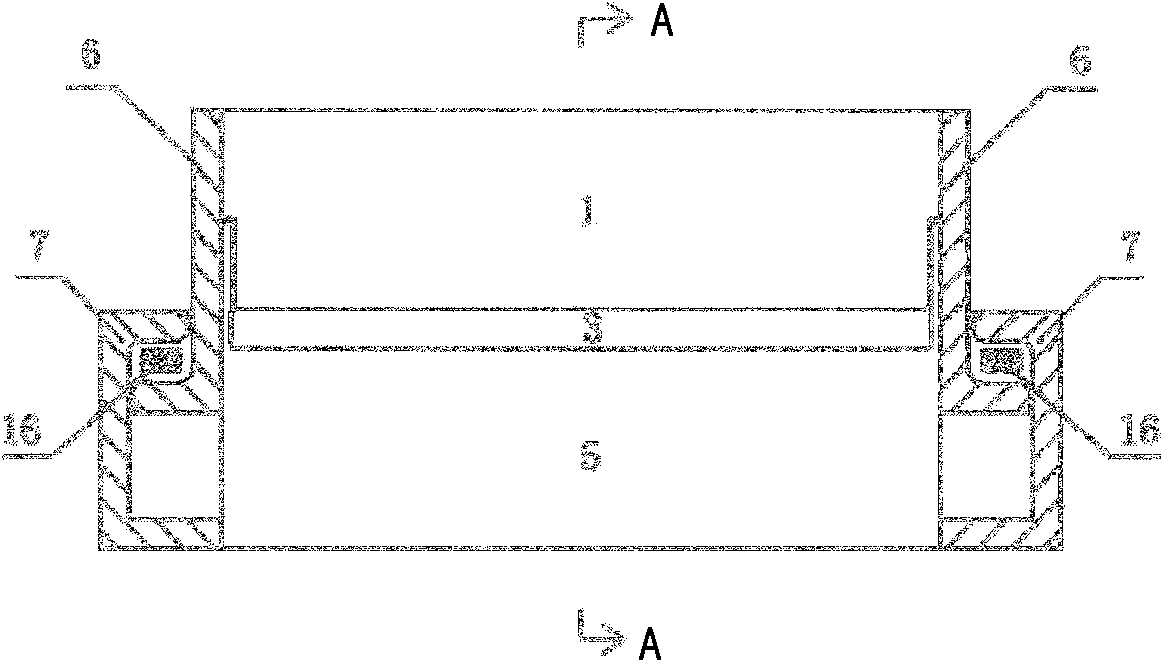

[0037] The anti-pull type friction pendulum shock-absorbing and isolating support of the present invention is based on a hyperboloid spherical shock-absorbing and isolating support, and a sliding plate is added, and an L-shaped upper baffle 6 and a [-shaped lower baffle 7 are provided. A new type of support is formed. It is mainly used for bridge structures in strong earthquake areas.

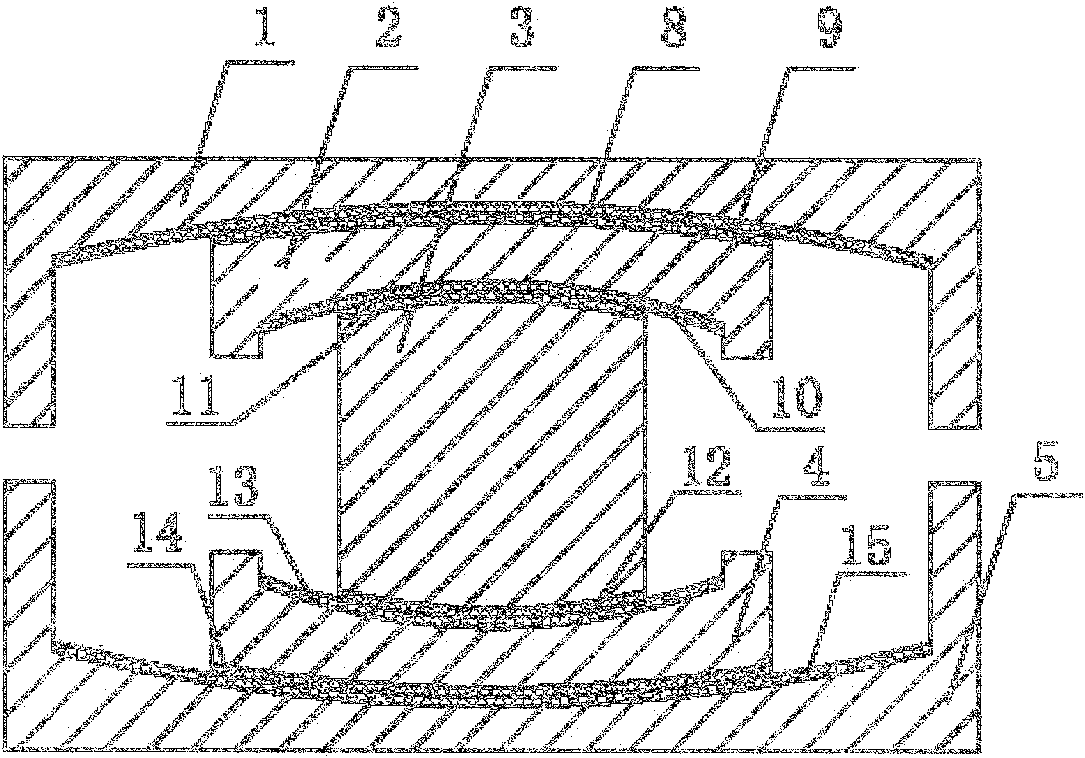

[0038] Such as Figure 1 to Figure 3 As shown, the anti-pull friction pendulum shock-absorbing bearing is mainly composed of an upper support plate 1, an upper slide plate 2, a middle slide plate 3, a lower slide plate 4, a lower support plate 5, an L-shaped upper baffle plate 6 and a [type lower plate Baffle plate 7 etc. are formed. The upper slide plate 2, the middle slide plate 3, and the lower slide plate 4 are arranged between the upper support plate 1 and the lower support plate 5 from top to bottom.

[0039] The concave cylindrical surface of the upper support plate 1 is welded and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com