Method for testing thermal resistance of high-power silicon carbide diode

A technology of silicon carbide diodes and testing methods, applied in the direction of thermal development of materials, etc., can solve the problems of long time, complicated operation method and high cost, and achieve the effect of wide application range, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

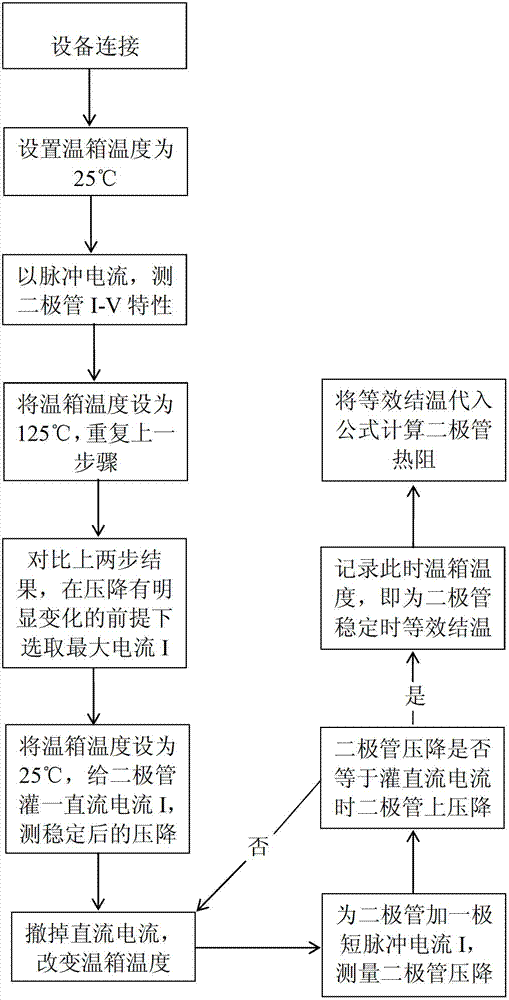

[0027] A high-power silicon carbide diode thermal resistance test method:

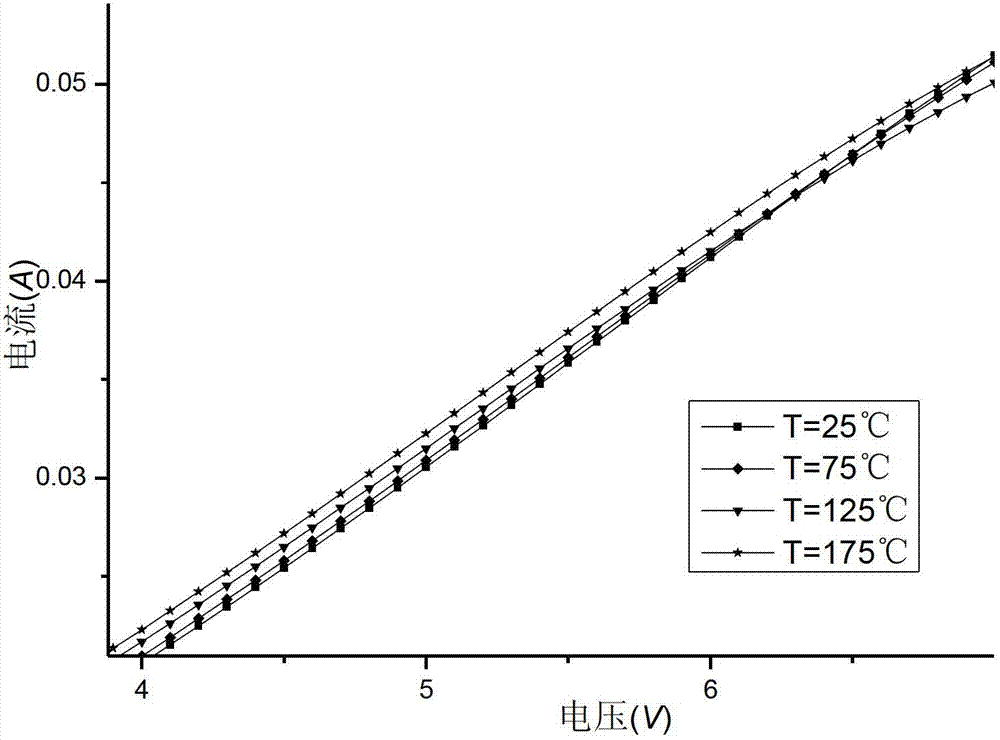

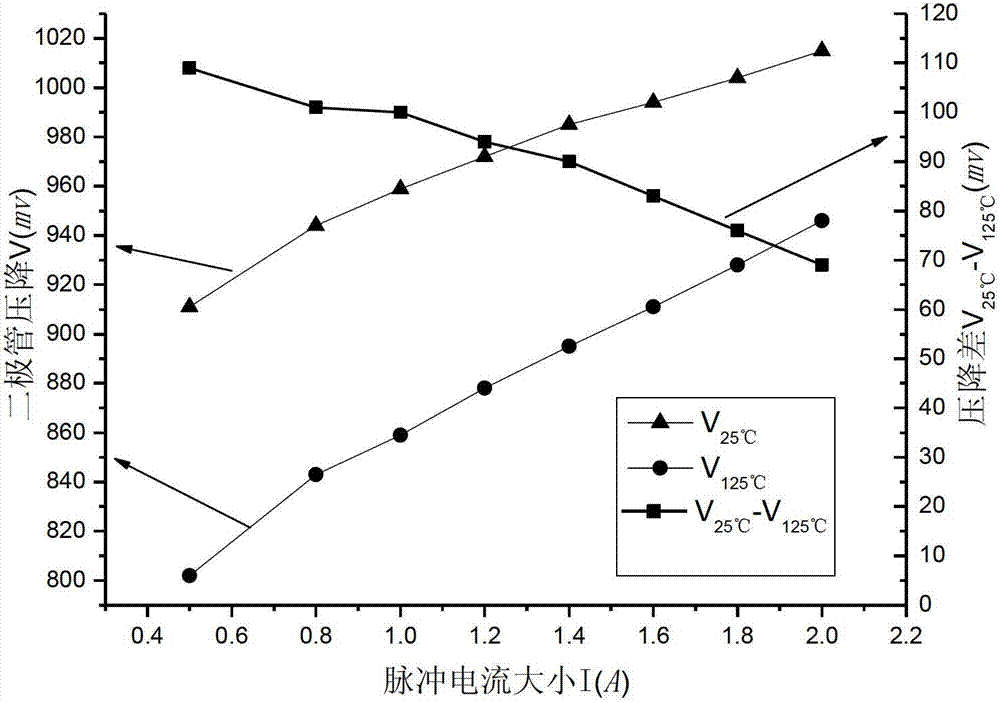

[0028] Step 1. Place the insulating substrate on which the diode to be tested is placed in the temperature control box, and adjust the temperature control box to 25°C. According to the scope of the safe working area of the diode to be tested and ensure that the device to be tested can work normally, Apply a single current pulse with a pulse width of 200μs to both ends of the diode to be tested, and the pulse current values are 0.5A, 0.8A, 1.0A, 1.2A, 1.4A, 1.6A, 1.8A, and 2.0A in sequence, and record them respectively The voltage drop across the diode under different pulse currents,

[0029] Step 2. Raise the temperature of the incubator to 125°C. According to the range of the safe working area of the diode to be tested and ensure that the device to be tested can work normally, apply a single current pulse with a pulse width of 200 μs to both ends of the diode to be tested. The current values ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com