Current transformer

A technology for current transformers and iron cores, applied in the directions of inductors, transformer/inductor cores, transformer/inductor coils/windings/connections, etc. The output waveform is easy to saturate and distort, and achieve the effect of eliminating the secondary and trailing after fault removal, the number of secondary turns, and the large cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

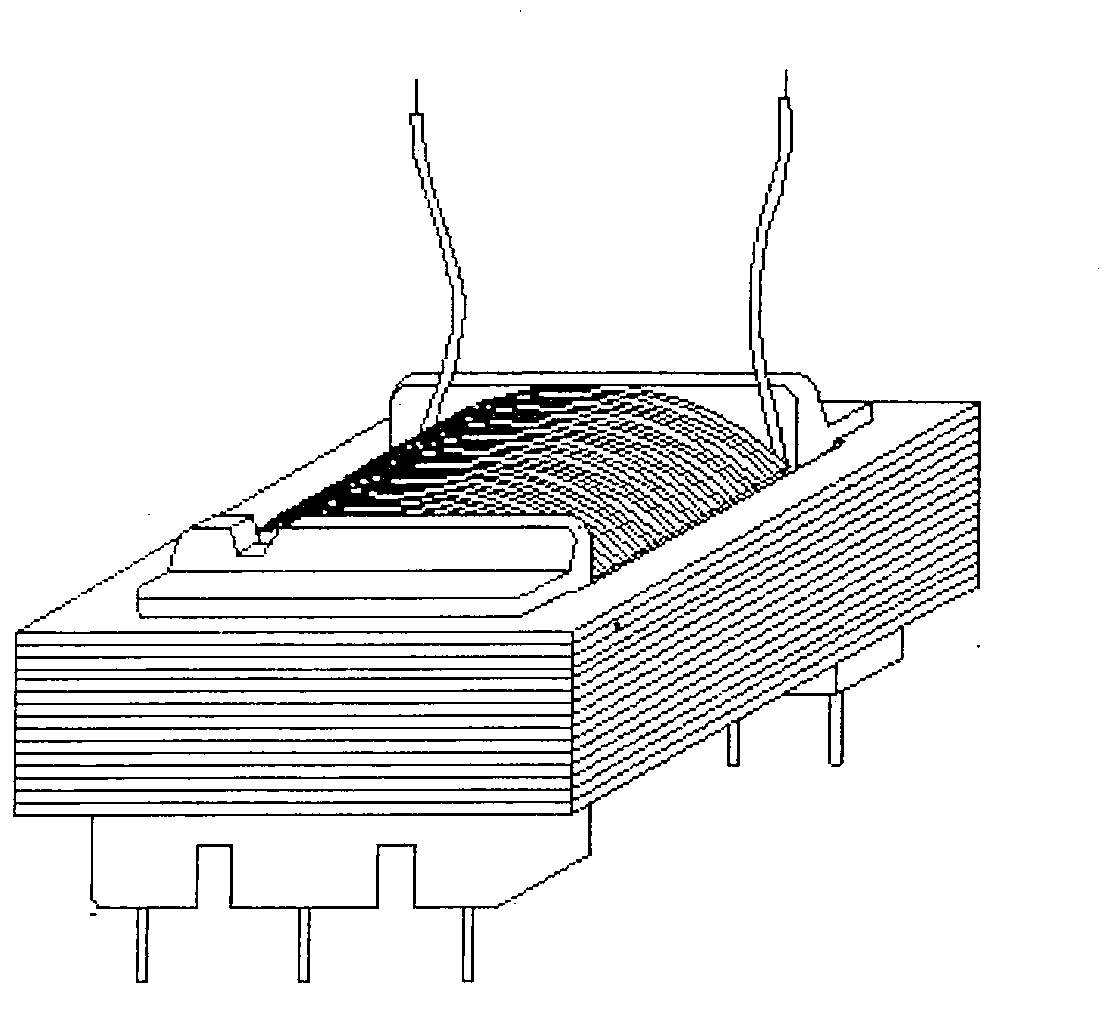

[0027] Such as figure 1 As shown, a current transformer includes an iron core, a primary winding and a secondary winding, and the cross section of the iron core is 1cm 2 -4cm 2 ; The iron core is provided with at least one air gap along the direction of cutting magnetic force lines; the number of turns of the primary winding is 1 turn-25 turns, and the number of turns of the secondary winding is 2000 turns-10000 turns; The coil diameter of the winding is Φ0.06mm-Φ0.21mm. The number of turns of the primary winding is preferably 1-15 turns, and 8 turns are used in this embodiment, and the number of turns of the secondary winding is preferably 2500 turns-6000 turns, and 2500 turns are used in this embodiment. The cross-section of the iron core refers to the cross-section of the part of the iron core that passes through the winding on one side and the secondary winding, and the cross-sectional area is 3.5cm 2 . The coil diameter of the secondary winding is 0.10mm.

[0028] Th...

Embodiment 2

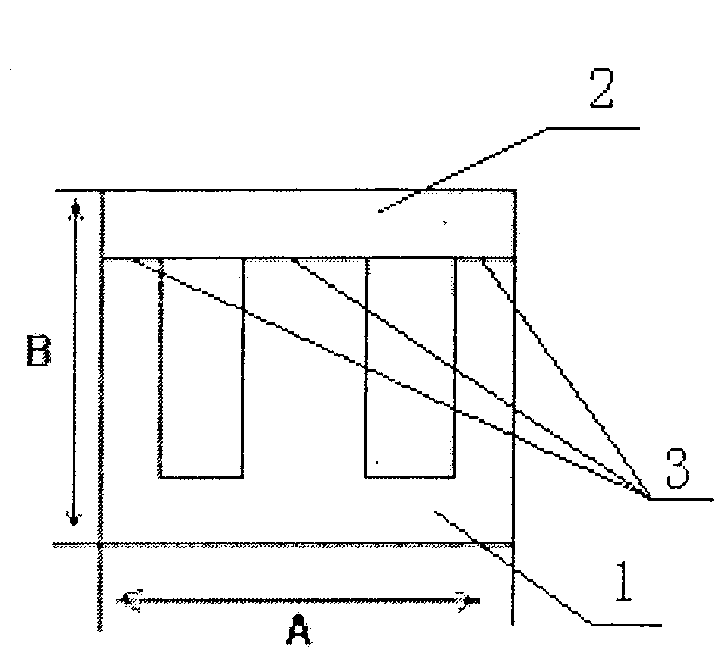

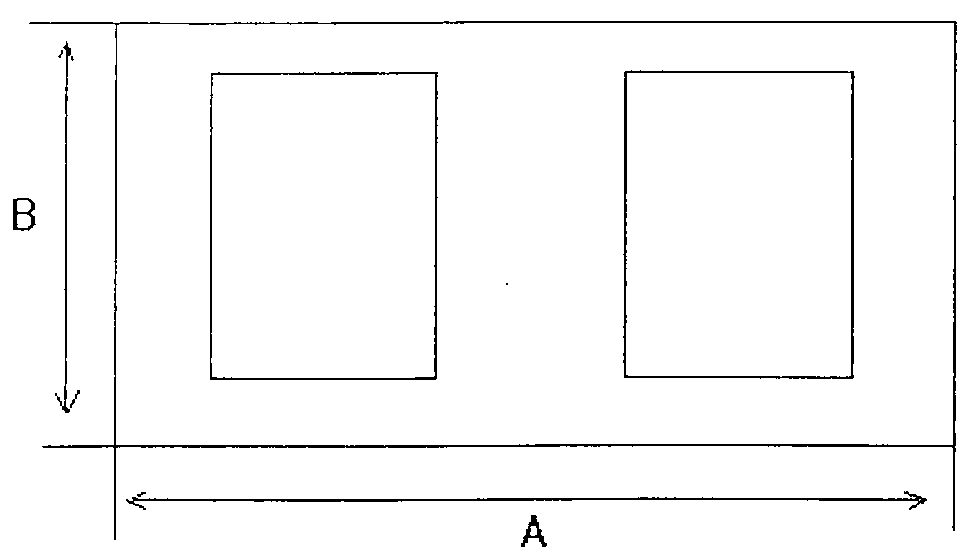

[0030] Such as Figure 7 with Figure 8 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the iron core of this embodiment adopts an annular notch iron core, and the iron core cross-sectional area is 2cm 2 , the number of turns of the primary winding is 5 turns, the number of turns of the secondary winding is 4000 turns, and the coil diameter of the secondary winding is 0.08mm. The iron core may be composed of a pair of annular notched iron cores, or may be composed of at least two pairs of annular notched iron cores superimposed. Such as image 3 The illustrated embodiment employs only an annular iron core provided with an air gap 8 . The outer diameter A of the annular iron core is 18mm-40mm, the inner diameter B is 12mm-30mm, and the thickness C is 6mm-18mm. In this embodiment, the outer diameter B is preferably 36mm, the inner diameter A is 20mm, and the thickness C is 16mm. Of course, the annular iron core with air gap and the ann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com