Thermal oxidation system with liquid accumulation preventing function and thermal oxidation method

An oxidation system, silicon oxide technology, applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of wafer quality decline, product scrap, pollution of the furnace environment, etc., to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The features and technical effects of the technical solution of the present invention will be described in detail below with reference to the accompanying drawings and combined with schematic embodiments, disclosing an improved thermal oxidation system and its method to avoid the accumulation of liquid water in the reaction furnace. It should be noted that similar reference numerals represent similar structures, and the terms "first", "second", "upper", "lower" and the like used in this application can be used to modify various system components and manufacturing processes . These modifications do not imply a spatial, sequential, or hierarchical relationship of the modified system components and manufacturing processes unless specifically stated.

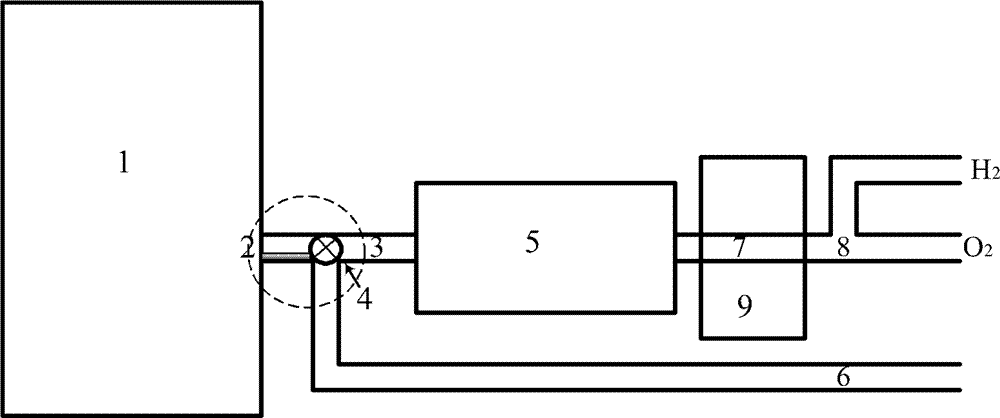

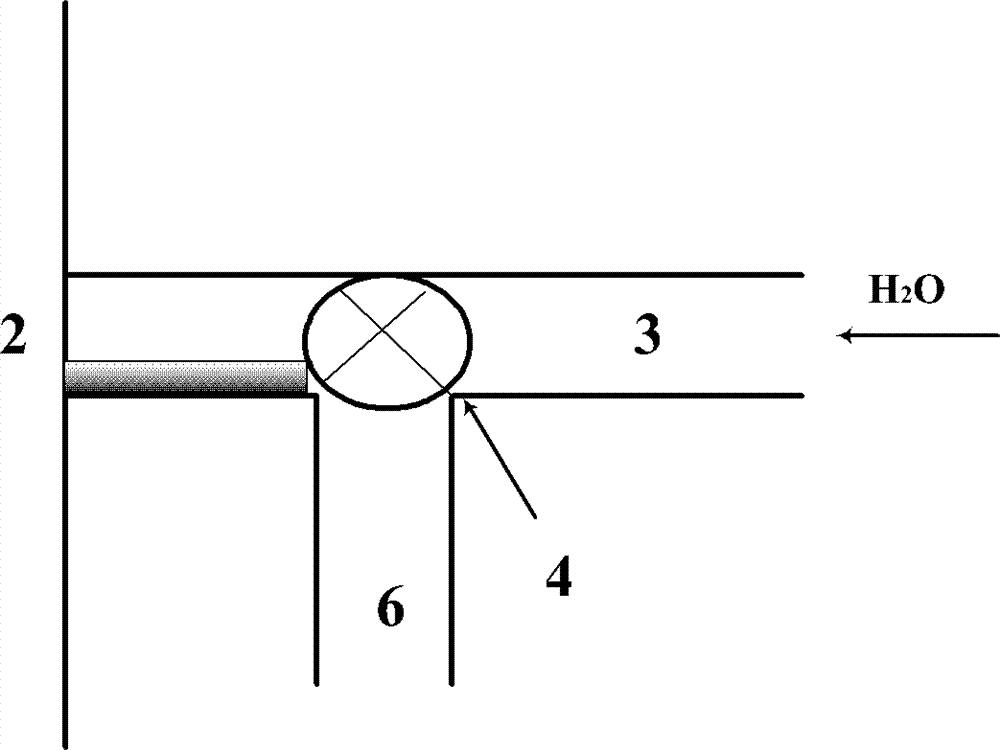

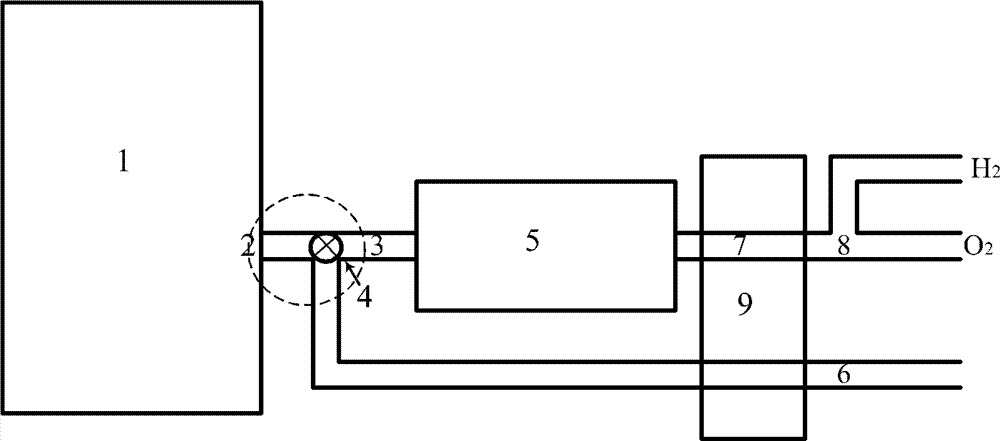

[0020] Such as Figure 2A Shown is the preparation of SiO by wet oxidation according to the present invention 2 thermal oxidation system. The reaction furnace 1 has an air inlet 2 for the reaction gas (others such as the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com