Drive device for pivoting adjustable blades of a turbomachine

A technology of driving device and turbine, which is applied to components of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., can solve the problem of endangering the reliability and integrity of driving devices, the inability to implement micro adjustments, large load and other issues, to save weight, improve force introduction, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

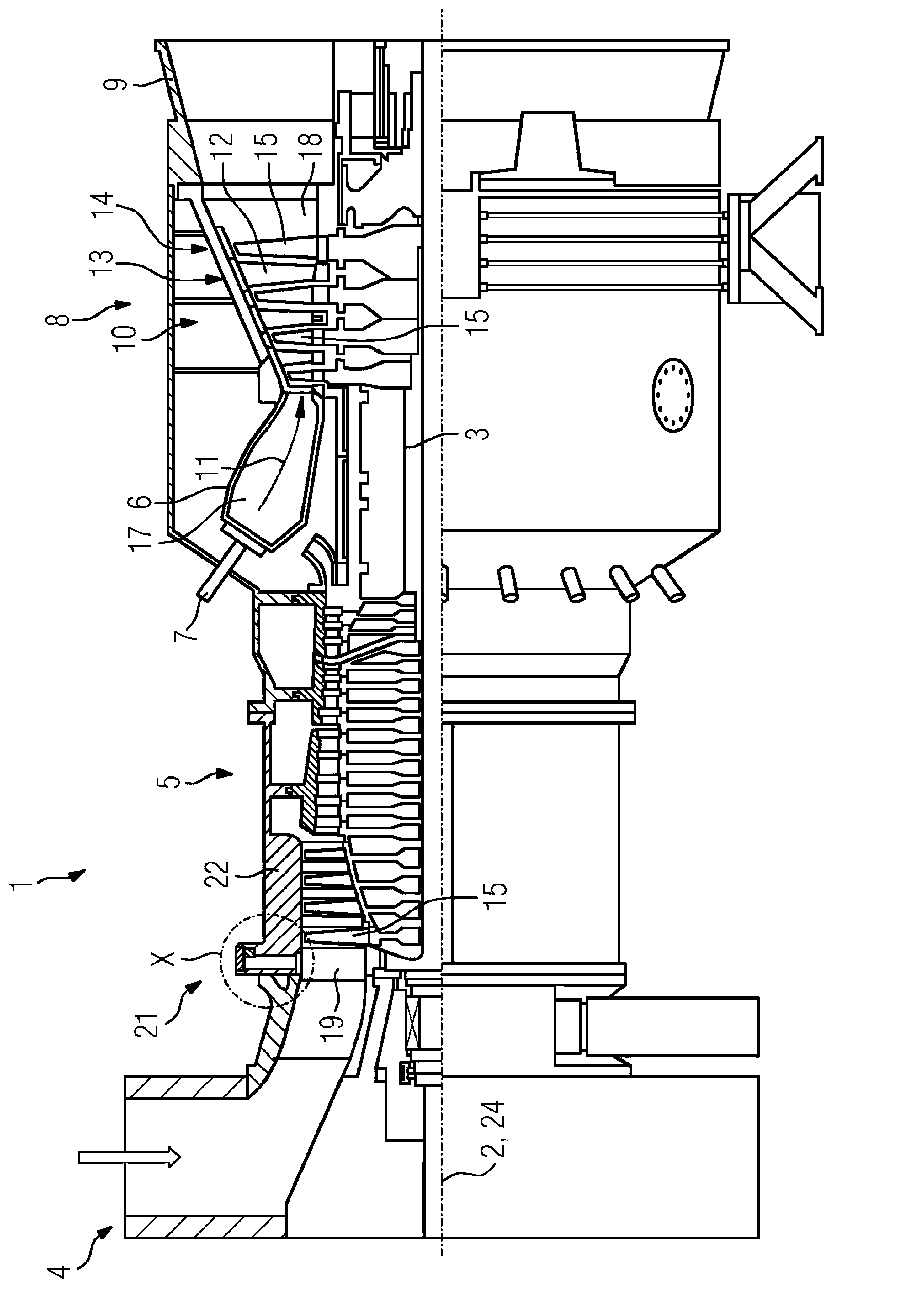

[0031] figure 1 A longitudinal partial section through a turbine designed as a stationary gas turbine 1 is shown in a longitudinal partial section. The gas turbine 1 is provided for generating electricity. The gas turbine internally has a rotor 3 mounted in rotation about an axis of rotation 2 , which is also referred to as a turbine rotor. Along the rotor 3 there follows an intake housing 4 , a compressor 5 , an annular annular combustion chamber 6 with a plurality of burners 7 arranged rotationally symmetrically to one another, a turbine unit 8 and an exhaust gas housing 9 . The annular combustion chamber 6 forms a combustion chamber 17 connected to an annular hot gas channel 18 . There, four successively connected turbine stages 10 form a turbine unit 8 . Each turbine stage 10 is formed by two blade rings. Viewed in the flow direction of the hot gas 11 generated in the annular combustion chamber 6 , each blade row 13 is followed by a row 14 formed by rotor blades 15 in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap