Method for controlling edge flatness defects of cold-rolling strip steel

A technology of cold-rolled strip steel and strip steel, which is applied in the field of controlling shape defects at the edge of cold-rolled strip steel, can solve the problems that the edge of the strip steel is prone to shape defects and cannot be eliminated by the shape control system, and achieves Avoid the effect of overshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0048] A method for controlling the shape defects at the edge of cold-rolled steel strip, the method comprises the steps of:

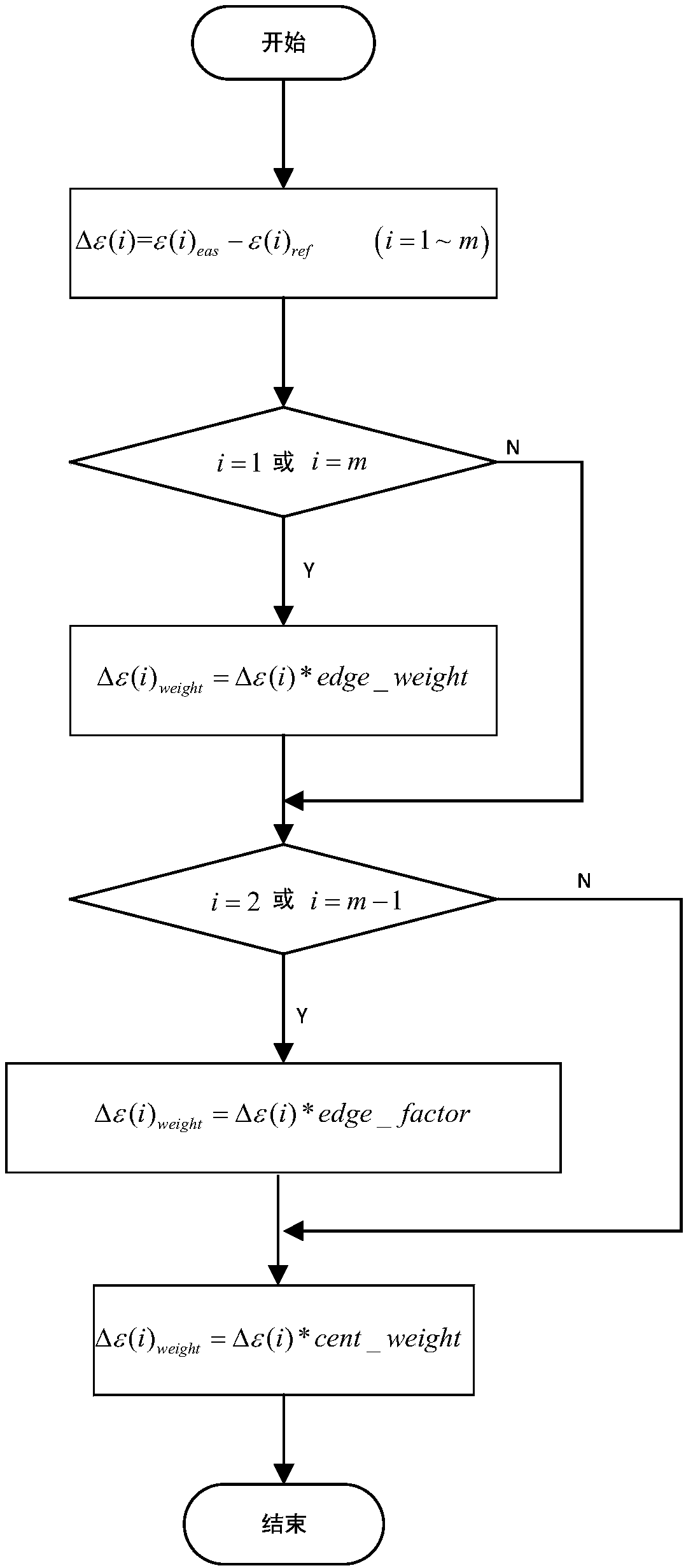

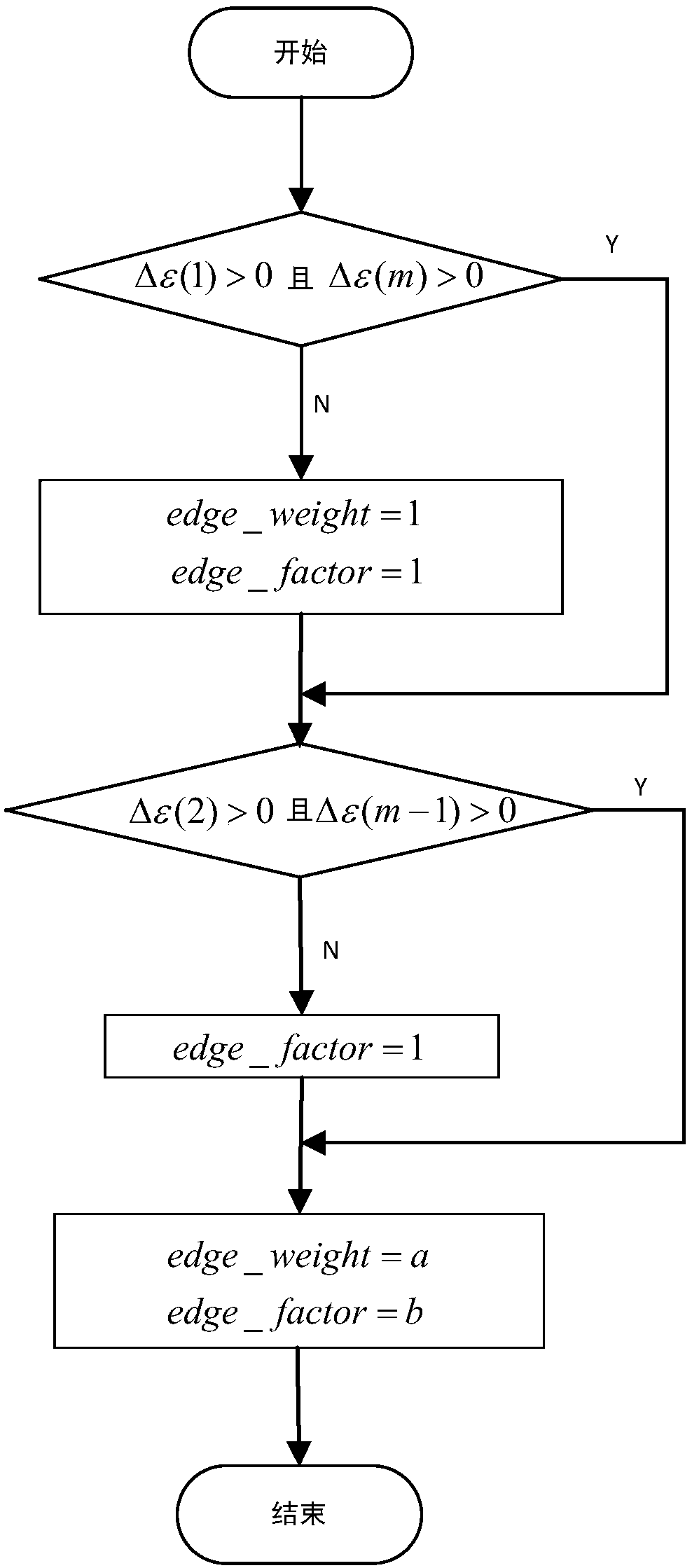

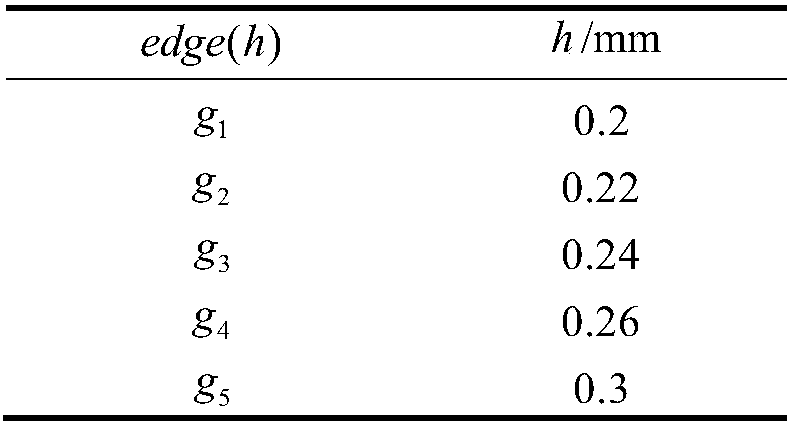

[0049] (1) Calculation of plate shape deviation

[0050] Receive the target shape value distribution signal and the shape value distribution signal measured by the shape meter, calculate the discrete shape deviation value according to the measured shape value distribution method, and the discrete shape deviation value can represent the horizontal difference of the strip steel The shape state at the location. The formula for calculating the shape deviation of each section of the strip is as follows:

[0051] Δε(i)=ε(i) eas -ε(i) ref (i=1, 2, 3...m)

[0052] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com